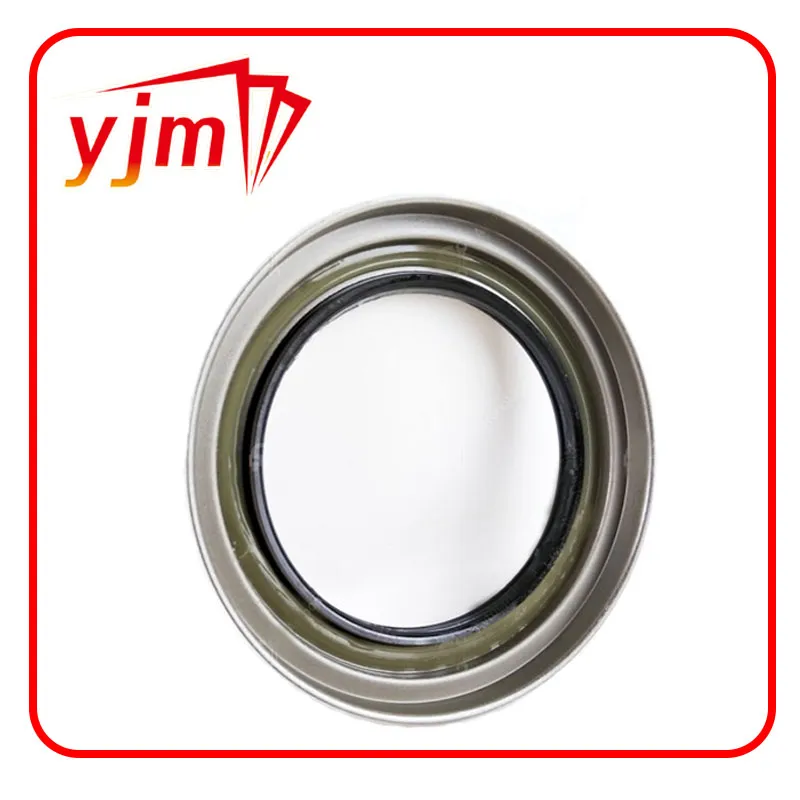

SEAL – OEM Genuine Toyota Oil (9031672001), Leak-Proof Fit

Field notes on the SEAL, OIL Genuine Toyota (9031672001)

If you work around Toyota powertrains long enough, you learn a simple truth: a tiny oil seal can make or break a rebuild. This one—part numbers 90316-72001 / 9031672001—shows up in procurement lists a lot. The version from YJM (Brand YJM, manufacturer ref 9331578841292) is a practical alternative many shops ask about. To be honest, availability and traceable quality matter more than hype.

What’s trending and why it matters

Industry trend check: low-friction lip geometries, better heat/oil resistance (FKM uptick), and tighter runout control. Electrification hasn’t killed rotary shaft seals—aux drives, reduction boxes, and hybrids still need them. Counterfeits remain a headache, so source traceability and standards compliance are, frankly, non-negotiable.

Product snapshot (specs at a glance)

| OEM P/N | 90316-72001 (aka 9031672001) |

| Brand / Mfr Ref | YJM / 9331578841292 |

| Origin | JULU INDUSTRY AREA, XINGTAI CITY, HEBEI, CHINA 055250 |

| Material options | NBR (standard) or FKM (heat/oil enhanced) |

| Hardness | ≈72 ±3 Shore A (rubber element) |

| Temp range | NBR: -30~+120°C; FKM: -20~+200°C (real-world use may vary) |

| Lip/spring | Spring-loaded primary lip + dust lip; stainless garter spring |

| Speed/pressure | ≤10 m/s; ≤0.05 MPa typical non-pressurized housings |

| Standards | ISO 6194, ASTM D2000 materials guidance |

| Service life | ≈80k–150k km depending on shaft finish, fluid, duty |

Process flow, testing, and QA signals

Materials are compounded (NBR/FKM per ASTM D2000 callouts), steel case pre-treated, lips molded and post-cured, then spring set. Criticals: lip edge radius, interference fit, and runout. Typical testing includes hardness (ASTM D2240), volume change in IRM oil (ASTM D471), and rotary lip endurance under ISO 6194 methods. Shops tell me a light oil film on install plus a clean 0.2–0.4 μm Ra shaft finish is where leaks live or die.

Where it’s used

Applications include rotary shaft locations in selected Toyota assemblies referencing 90316-72001. Always verify fitment by VIN and housing dimensions; even tiny OD variance can cause spin or seepage. Many customers say the SEAL lands best where moderate speeds and hot oil exposure are routine.

Why teams pick this SEAL

- Fitment consistency and stable lip load (that “just-right” press feel).

- FKM option for higher-temp synthetic oils.

- Reasonable lead times versus dealer backorders.

Vendor comparison (quick buyer’s view)

| Vendor | Fitment | Certs | Lead time | Price | Customization |

|---|---|---|---|---|---|

| YJM (this SEAL) | OEM-equivalent | ISO 9001/IATF 16949 (supplier-declared) | ≈7–15 days | Mid | Material/lip/spring options |

| OEM dealer | OEM | OEM internal | 3–10 days (stock dependent) | High | None |

| Generic aftermarket | Varies | Limited/varies | Unpredictable | Low | Limited |

Customization and test data

Options include NBR vs FKM, dual-dust lip, spring wire grade, and private labeling. Internal lab snapshots: NBR ΔV in IRM903 oil @100°C, 70h ≈ +12%; FKM ΔV @150°C, 70h ≈ +3% (ASTM D471). Hardness 72±3 Shore A; torque rise at 1500 rpm stayed within expected ISO 6194 envelopes. Your mileage will vary with shaft finish and oil chemistry.

Case snapshots (illustrative)

- Independent shop swap: after 20k km check, no visible seep; installer cited “clean bore, light oil on lip” as key.

- Fleet maintenance note: FKM version held up better with extended drains and higher sump temps.

Part IDs to match: OEM 90316-72001 / 9031672001; Manufacturer part number 9331578841292. Packaging from YJM is usually scannable and batch-coded—small touch, big help against mix-ups.

Certifications: supplier-stated ISO 9001 and IATF 16949 alignment; materials typically RoHS/REACH compliant. Request current certificates and PPAP if you’re on a Tier-1 audit trail.

Final take

If you need an OEM-referenced SEAL with predictable fit and the option to step up to FKM, this is a sensible line item. Just don’t skip the basics: inspect the shaft, gauge the bore, and lube the lip. Simple things, big payoffs.

References

- ISO 6194 – Rotary shaft lip-type seals for gas and liquid.

- ASTM D2000 – Standard Classification System for Rubber Products in Automotive Applications.

- ASTM D471 – Standard Test Method for Rubber Property—Effect of Liquids.

- IATF 16949 – Automotive Quality Management System Requirements.

-

Seal 12x20x5: Precision Radial Shaft Seals for Industrial Reliability

News Nov.24,2025

-

Seal 12x18x5: Essential Guide to Specifications, Applications & Vendors

News Nov.24,2025

-

Understanding Seal 12 20 5: Applications, Specifications & Industry Insights

News Nov.23,2025

-

Durable Oil Seal 85x110x12 – Reliable Sealing Solutions for Industry

News Nov.23,2025

-

Durable and Precise Oil Seal 75x95x10 for Efficient Machinery | YJM Seal

News Nov.22,2025

-

Durable Oil Seal 75x100x10 for Reliable Industrial Performance | YJM Seal

News Nov.22,2025

-

High-Quality Oil Seal 65x90x10 | Durable & Reliable Sealing Solutions

News Nov.22,2025

Products categories