Oil Pump Seal 9031143010 - OEM-Grade, Heat & Leak Resistant

Oil Pump Seal 9031143010 is a key solution in the manufacturing industry, specifically within Mechanical equipment manufacturing industry and Seal manufacturing. This article explores how JULU YJM HWMF SEAL CO.,LTD. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Oil Pump Seal 9031143010 Overview

- Benefits & Use Cases of Oil Pump Seal 9031143010 in Seal manufacturing

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Oil Pump Seal 9031143010 from JULU YJM HWMF SEAL CO.,LTD.

Oil Pump Seal 9031143010 Overview

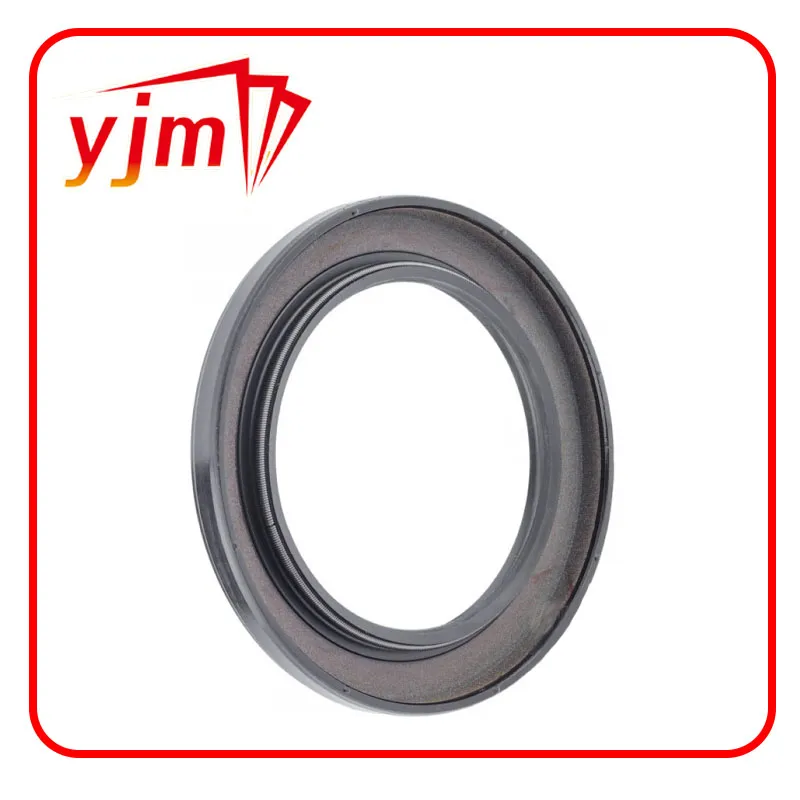

The Oil Pump Seal 9031143010 is a precision-engineered radial shaft seal designed to prevent oil leakage and ingress of contaminants at the pump drive interface. In mechanical equipment manufacturing and the broader seal manufacturing domain, this component plays a mission-critical role: it stabilizes lubrication regimes, protects bearings, and sustains hydraulic efficiency. For B2B decision makers, that translates to longer mean time between failures (MTBF), fewer unplanned stoppages, and predictable maintenance windows across production fleets.

Typical configurations for the Oil Pump Seal 9031143010 include a spring-energized elastomeric lip, metal case reinforcement, and optional dust lips. Material options often include NBR for balanced oil resistance and cost efficiency, and FKM for elevated thermal and chemical exposure. Seals of this class are commonly engineered for oil temperatures ranging from sub-zero environments to high-heat duty cycles, low differential pressure at the shaft interface, and surface speeds aligned with automotive and industrial pump outputs. Dimensional tolerances and surface finish compatibility (shaft Ra, lead, and hardness) ensure reliable sealing over prolonged service hours.

JULU YJM HWMF SEAL CO.,LTD. manufactures the Oil Pump Seal 9031143010 with strict process control, dependable compound formulation, and consistent lip geometry—key variables that influence break-in behavior, friction, and lifetime. Our application engineers collaborate with OEMs and Tier suppliers to align seal design with shaft metallurgy, housing tolerances, and lubrication strategy, helping you validate performance quickly and cost-effectively.

Benefits & Use Cases of Oil Pump Seal 9031143010 in Seal manufacturing

In seal manufacturing, the Oil Pump Seal 9031143010 is specified across automotive oil pumps, light industrial hydraulic modules, and compact gear pumps found in assembly, packaging, and material-handling equipment. It is also suited to auxiliary lubrication circuits in compressors and stationary engines where leakage control directly affects uptime and compliance. The seal’s balanced lip design and case rigidity support consistent contact pressure, minimizing micro-leaks during cold starts and thermal transients.

- Performance stability: optimized lip profile for steady film formation, reduced heat generation, and lower wear at the shaft interface.

- Material flexibility: NBR and FKM options to handle a wide spectrum of base oils and additives, as well as elevated temperatures.

- Contamination control: optional dust lip configuration improves barrier performance in dusty or splash-prone environments.

- Fit-for-purpose geometry: stable metal case and precise OD interference to resist spin-out and maintain concentricity.

Backed by JULU YJM HWMF SEAL CO.,LTD.’s application know-how, the Oil Pump Seal 9031143010 integrates seamlessly into OEM and aftermarket programs. Our team supports PPAP-level documentation upon request, advises on shaft lead correction, and recommends storage/handling practices that preserve lip integrity before installation—so your lines run smoother with fewer start-up anomalies.

Cost, Maintenance & User Experience

Total cost of ownership for the Oil Pump Seal 9031143010 hinges on durability, installation accuracy, and fluid compatibility. By pairing proven elastomer compounds with consistent lip preload, JULU YJM HWMF SEAL CO.,LTD. helps extend seal life and stabilize MTBF. Less leakage means fewer oil top-ups, cleaner workcells, lower environmental fees, and reduced customer warranty exposure—an ROI that compounds over thousands of units. For B2B leaders, this equates to predictable spend and a lower cost-per-operating-hour.

Users in the mechanical equipment manufacturing industry emphasize three benefits: straightforward installation, stable running-in, and consistent quality across batches. To maximize results, ensure correct shaft surface finish and hardness, verify housing bore tolerances, lubricate the lip during assembly, and avoid dry-running during start-up. Many customers standardize the Oil Pump Seal 9031143010 across platforms to reduce SKU complexity and speed procurement. Field feedback highlights clean removal without case deformation and minimal groove wear on properly hardened shafts—key to quicker service intervals and less rework.

Sustainability & Market Trends in manufacturing

Sustainability in modern manufacturing prioritizes leakage prevention, energy efficiency, and material stewardship. Effective oil sealing reduces lubricant consumption, prevents floor contamination, and helps facilities meet environmental targets. As regulations tighten around VOCs, waste handling, and machine cleanliness, a reliable seal such as the Oil Pump Seal 9031143010 becomes a practical lever to improve ESG metrics without redesigning entire systems. Additionally, specifying materials compatible with common eco-labeled lubricants can support broader corporate sustainability initiatives.

Market trends point to compact pump designs with higher shaft speeds, more aggressive additive packages, and wider temperature windows. JULU YJM HWMF SEAL CO.,LTD. tracks these shifts and develops formulations and geometries that maintain seal integrity under higher dynamic loads. We also emphasize responsible sourcing and process efficiency, aiming to reduce scrap and optimize logistics. Whether you are updating an existing platform or launching a next-generation pump, our engineering support helps align performance with sustainability and compliance expectations.

Conclusion on Oil Pump Seal 9031143010 from JULU YJM HWMF SEAL CO.,LTD.

The Oil Pump Seal 9031143010 delivers the sealing reliability that manufacturers need to reduce downtime, protect assets, and control lifecycle costs. Its balanced lip design, material flexibility, and robust case support consistent performance across automotive and industrial pump applications. With JULU YJM HWMF SEAL CO.,LTD., you gain a responsive partner focused on quality, application fit, and supply continuity. Contact us: email: yjm006@hwmf.com — Visit our website: https://www.yjmseal.com

-

Seal 12x20x5: Precision Radial Shaft Seals for Industrial Reliability

News Nov.24,2025

-

Seal 12x18x5: Essential Guide to Specifications, Applications & Vendors

News Nov.24,2025

-

Understanding Seal 12 20 5: Applications, Specifications & Industry Insights

News Nov.23,2025

-

Durable Oil Seal 85x110x12 – Reliable Sealing Solutions for Industry

News Nov.23,2025

-

Durable and Precise Oil Seal 75x95x10 for Efficient Machinery | YJM Seal

News Nov.22,2025

-

Durable Oil Seal 75x100x10 for Reliable Industrial Performance | YJM Seal

News Nov.22,2025

-

High-Quality Oil Seal 65x90x10 | Durable & Reliable Sealing Solutions

News Nov.22,2025

Products categories