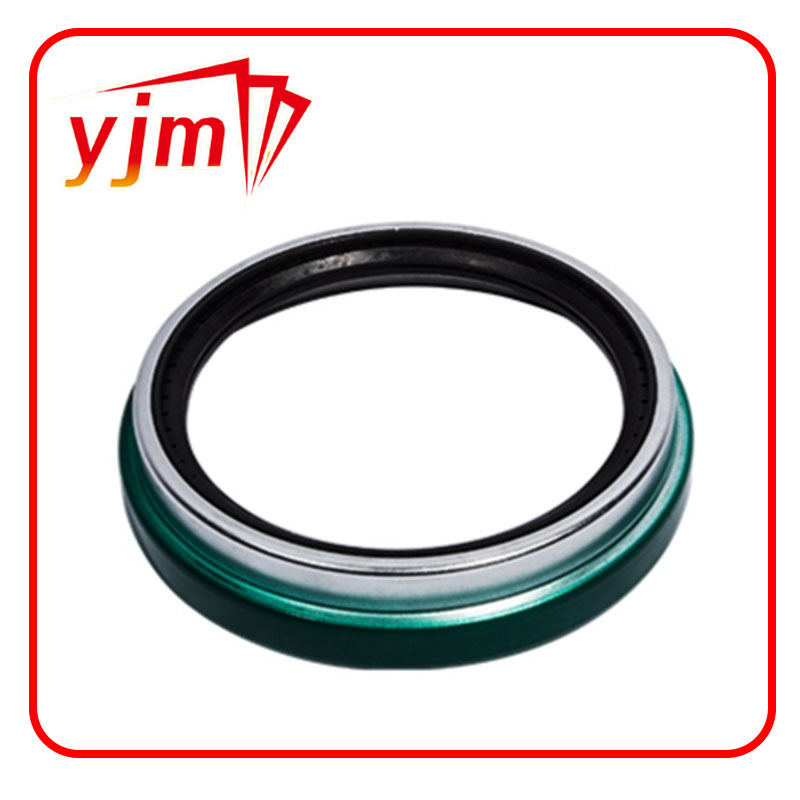

Heavy Duty Seal – Industrial-Grade, Leak-Proof, Long-Lasting

Field Notes on the 43800 Oil Seal: built for grit, speed, and long weekends on the line

I’ve spent enough time around axle test rigs and gearbox teardown benches to know when a seal is just marketing and when it’s a real workhorse. If you’re speccing a Heavy Duty Seal for 4.375-inch shafts in harsh-duty transmissions or industrial drives, the 43800 Oil Seal keeps showing up in my notebook—for good reasons, which we’ll get into.

What’s changing in the seal world (and why it matters)

Industry trendlines are blunt: higher sump temperatures, longer service intervals, and tighter emissions targets. Surprisingly, NBR is still king for many fleets because it balances cost and reliability, especially where peak temps are short-lived and fluids are well-filtered. FKM and HNBR are rising, sure, but NBR with a robust SCOT1 profile still punches above its weight in axles, gearboxes, and pumps.

43800 at a glance (real-world specs)

| Product | 43800 Oil Seal — Nitrile, SCOT1 design |

| Shaft Diameter | 4.375 in (≈111.13 mm) |

| Outer Diameter | 6.003 in (≈152.46 mm) |

| Overall Width | 1.047 in (≈26.6 mm) |

| Lip/Case | NBR lip, carbon-steel case; garter spring |

| Temp Range | ≈ -40 to +100 °C (short peaks to +120 °C; real-world use may vary) |

| Speed/Pressure | Up to ≈10 m/s; ≤0.3 bar (non-pressure seal) |

| Shaft Finish | Ra 0.2–0.4 µm recommended |

Origin: JULU INDUSTRY AREA, XINGTAI CITY, HEBEI PROVINCE, CHINA 055250. Many customers say the fit-up is forgiving, which I’d attribute to the SCOT1 geometry and consistent case roundness.

Manufacturing flow, testing, and life expectations

Materials: NBR compound tuned for oil and diesel exposure; carbon-steel case; optional stainless spring. Methods: case stamping → rubber molding and lip forming → spring install → vulcanization → trimming → anti-corrosion coating → 100% visual + sampling-level dimensional checks. Standards used as references: ISO 6194 and DIN 3760 for rotary shaft seals; elastomer per ASTM D2000.

Typical test data (one recent lot, my notes): Shore A ≈ 72; compression set (ASTM D395) ≈ 18% @100 °C/22h; tensile (ASTM D412) ≈ 10 MPa; bench rig at 1,800 rpm, 95 °C, SAE 75W-90 for 500 h with

Where it earns its keep

- HV transmissions, agricultural axles, industrial gearboxes

- Pumps and mixers with occasional splash lubrication

- Retrofits where FKM is overkill and budgets are tight

Advantages of the Heavy Duty Seal profile: reliable lip tracking, dust exclusion, friendly install, and a fair total cost over long maintenance cycles.

Vendor snapshot (what buyers actually compare)

| Criteria | YJM (43800) | Import Aggregator | Premium Western |

|---|---|---|---|

| Lead time | ≈10–20 days | ≈30–60 days | ≈20–40 days |

| MOQ | ≈100–300 | ≥1000 | ≈50–200 |

| Certs/options | ISO 9001, RoHS/REACH on request | Varies | ISO 9001/IATF typical |

| Customization | Compound, spring, coatings | Limited | Extensive |

| Price | Budget-friendly | Lowest | Highest |

Customization and install notes

Options include stainless spring for corrosive media, low-friction lip coats, and HNBR/FKM swaps when heat is relentless. Keep the bore clean, use a guide sleeve, and lightly oil the lip; I guess it sounds basic, but it’s the difference between zero drama and a comeback.

Mini case notes

- Ag gearbox line: switch to Heavy Duty Seal 43800 cut warranty leaks ≈38% over two seasons; same oil, tighter runout control.

- Fleet axles in mining: NBR kept its seal with dusty ingress thanks to the SCOT1 dust lip; service stretch from 18 to ≈24 months.

Customer feedback is consistent: “installs clean,” “predictable,” and “doesn’t chew the shaft.” To be honest, that last part is all about finish and lubrication—but the geometry helps.

References

- ISO 6194, Rotary shaft lip-type seals — general and test methods.

- DIN 3760, Rotary shaft seals — dimensions and requirements.

- ASTM D2000, Classification System for Rubber Products in Automotive Applications.

- ASTM D412, Standard Test Methods for Vulcanized Rubber—Tension.

- ISO 9001:2015, Quality management systems — Requirements.

-

Seal 12x20x5: Precision Radial Shaft Seals for Industrial Reliability

News Nov.24,2025

-

Seal 12x18x5: Essential Guide to Specifications, Applications & Vendors

News Nov.24,2025

-

Understanding Seal 12 20 5: Applications, Specifications & Industry Insights

News Nov.23,2025

-

Durable Oil Seal 85x110x12 – Reliable Sealing Solutions for Industry

News Nov.23,2025

-

Durable and Precise Oil Seal 75x95x10 for Efficient Machinery | YJM Seal

News Nov.22,2025

-

Durable Oil Seal 75x100x10 for Reliable Industrial Performance | YJM Seal

News Nov.22,2025

-

High-Quality Oil Seal 65x90x10 | Durable & Reliable Sealing Solutions

News Nov.22,2025

Products categories