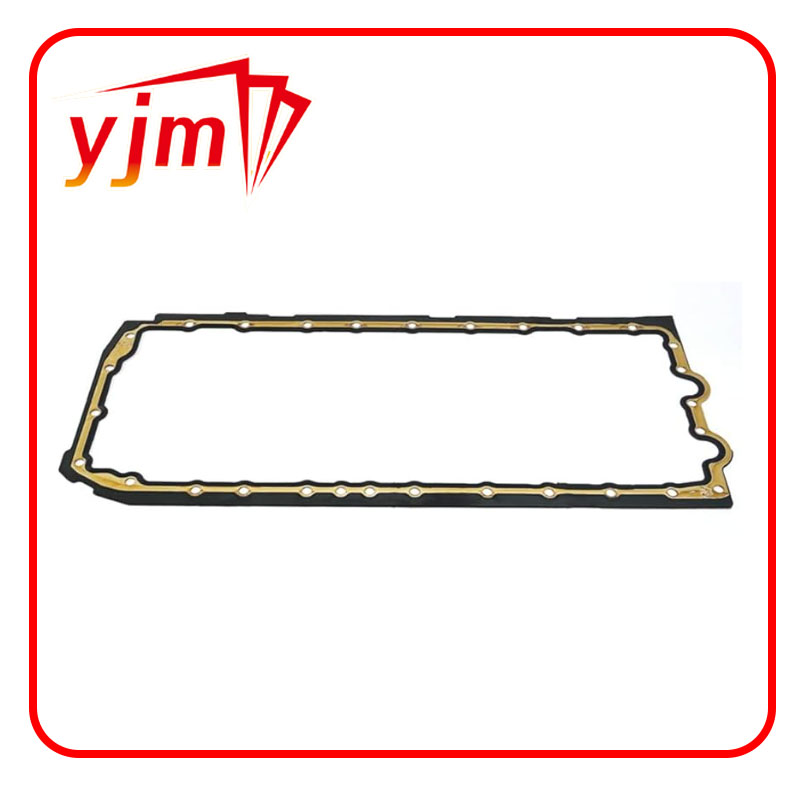

Oil Pan Gasket – Leak-Proof, High-Temp, OEM-Grade Seal

oil pan gasket,pan gasket,engine sump gasket,liquid gasket for oil pan is a key solution in the automotive industry, specifically within auto parts and Engine Parts. This article explores how JULU YJM HWMF SEAL CO.,LTD. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- oil pan gasket,pan gasket,engine sump gasket,liquid gasket for oil pan Overview

- Benefits & Use Cases of oil pan gasket,pan gasket,engine sump gasket,liquid gasket for oil pan in Engine Parts

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in automotive industry

- Conclusion on oil pan gasket,pan gasket,engine sump gasket,liquid gasket for oil pan from JULU YJM HWMF SEAL CO.,LTD.

oil pan gasket,pan gasket,engine sump gasket,liquid gasket for oil pan Overview

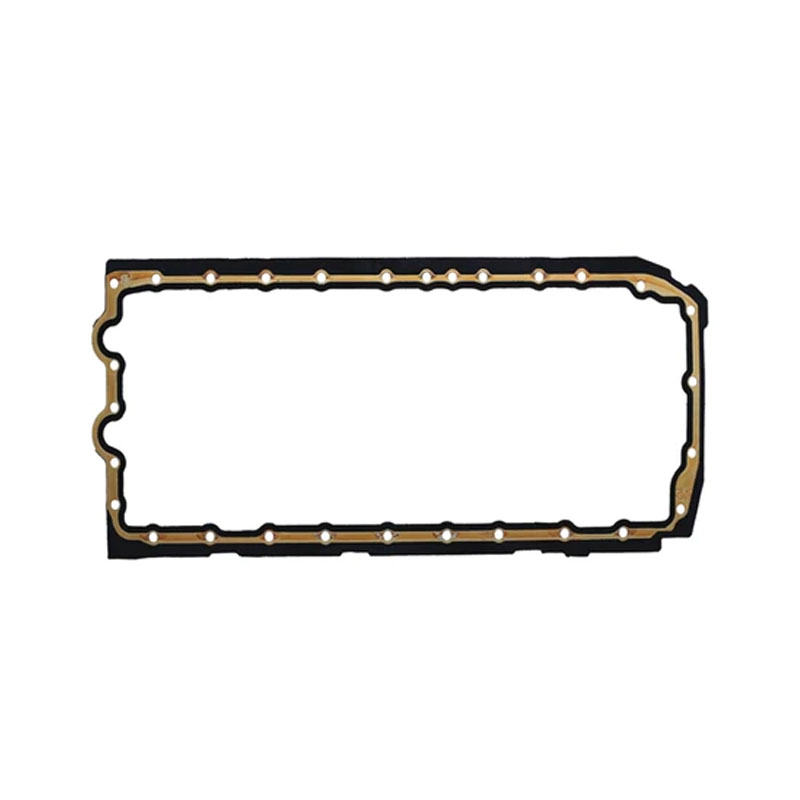

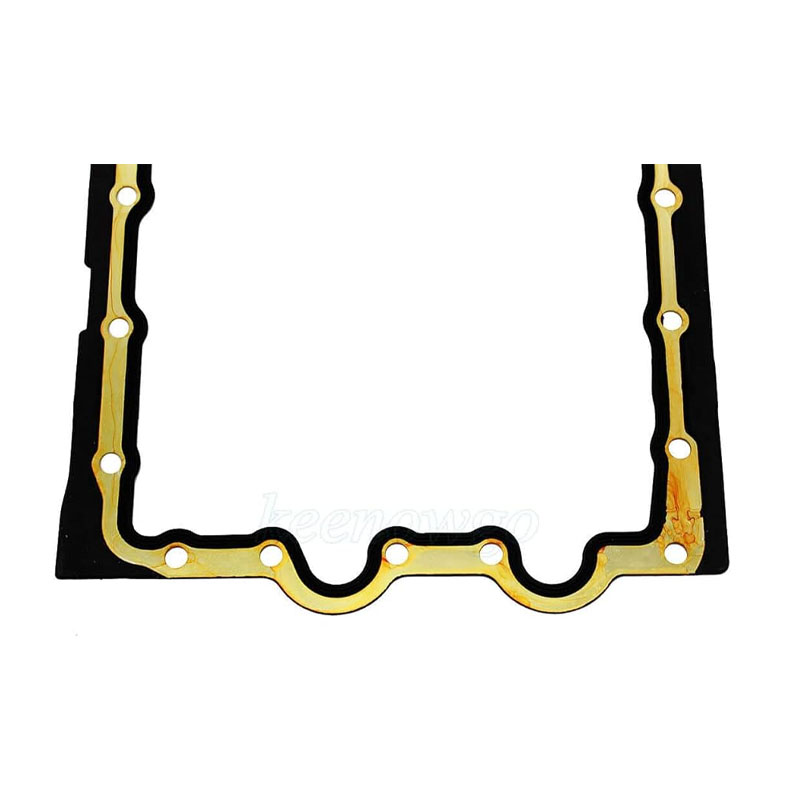

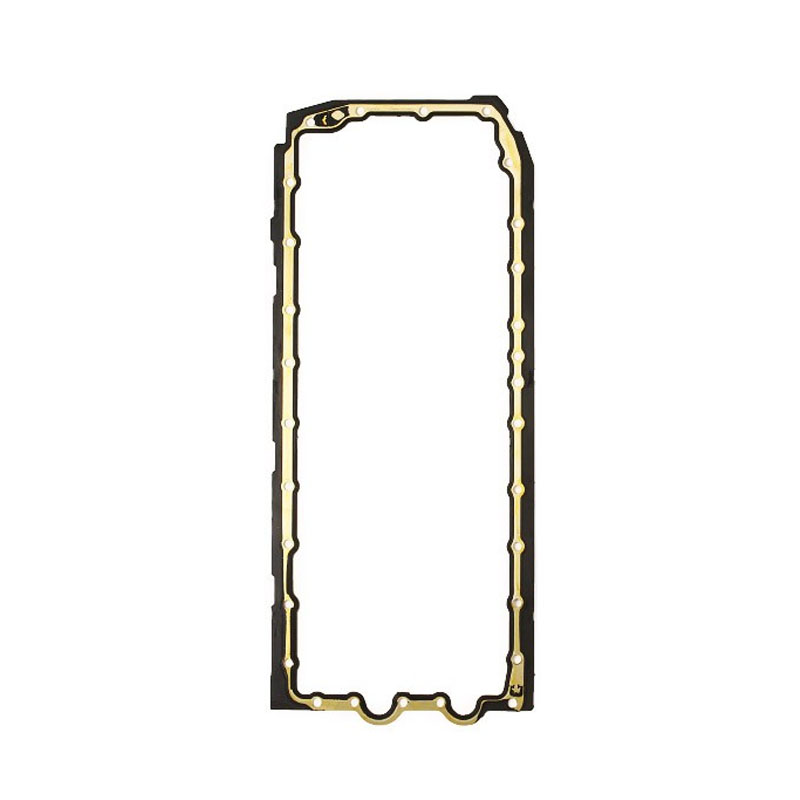

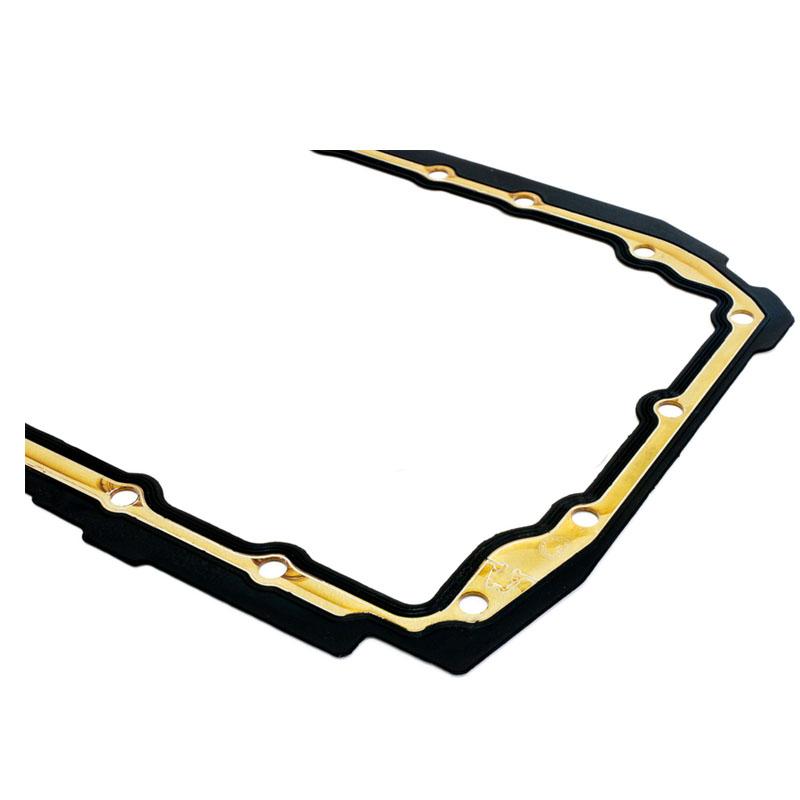

In modern powertrain design, the oil pan gasket (also called a pan gasket or engine sump gasket) is the primary static seal between the engine block and the sump, preventing oil seepage under thermal cycling, pressure pulses, and vibration. For B2B buyers, the choice of gasket directly influences warranty risk, service labor, and end-customer satisfaction. JULU YJM HWMF SEAL CO.,LTD. manufactures OE-comparable and aftermarket solutions, including molded rubber-on-steel carriers, fiber-reinforced composites, and complementary liquid gasket for oil pan applications where flange design or service strategies require form-in-place sealing.

Typical technical attributes include precise compression set control, oil and fuel additive resistance, and bead geometrics that maintain micro-seal integrity across uneven flange surfaces. For buyers serving European platforms, the product line covers key OE references such as BMW oil sump gasket (e.g., OE-ref 11137548031), along with broad Asian and American fitments. Engineering support includes guidance on surface roughness, bolt load distribution, and torque-to-yield practices—ensuring a robust seal on first assembly and during service. With materials ranging from premium NBR and FKM to silicone RTV and anaerobic chemistries for liquid gasket integration, JULU YJM HWMF SEAL CO.,LTD. is a reliable manufacturer committed to consistent quality and supply continuity.

Benefits & Use Cases of oil pan gasket,pan gasket,engine sump gasket,liquid gasket for oil pan in Engine Parts

Oil pan gaskets are used wherever the sump interfaces with the crankcase—passenger cars, light commercial vehicles, performance builds, and remanufacturing lines. In OE assembly and aftermarket service, the right pan gasket prevents leaks that can trigger low-oil warnings, contamination, and environmental non-compliance. For engines with cast aluminum pans and tight NVH targets, molded rubber-on-carrier solutions provide superior flange conformity and torque retention. For stamped steel pans or legacy designs, fiber or composite engine sump gasket options offer cost-effective sealing with strong crush resistance.

Competitive advantages of JULU YJM HWMF SEAL CO.,LTD. include:

- Material engineering: oil- and additive-resistant elastomers, FKM options for high-temperature duty cycles, and anti-stick coatings for clean service removal.

- Design precision: sealing beads, corner reinforcements, and controlled thickness for even compression under specified torque patterns.

- Form-in-place support: liquid gasket for oil pan solutions (e.g., RTV) for complex covers or service conditions where gasket substitution or hybrid sealing is preferred.

- Fitment coverage: targeted SKUs aligned to high-demand European and global applications, backed by drawings and PPAP-ready documentation upon request.

For B2B buyers, this translates to streamlined procurement, fewer leak-related callbacks, and faster technician throughput across dealer, fleet, and independent service networks.

Cost, Maintenance & User Experience

Total cost of ownership hinges on zero-leak performance, predictable installation, and reduced rework. JULU YJM HWMF SEAL CO.,LTD.’s oil pan gasket portfolio is engineered to minimize compression set and retain sealing force over long drain intervals, driving down warranty claims and labor-intensive revisits. When paired with proper surface prep and a controlled torque sequence, end users report clean, repeatable installs and fewer post-service seepages—especially critical for high-mileage fleets and warranty-sensitive programs.

From a procurement perspective, consistent dimensional tolerance and packaging integrity reduce waste on the line. For shops that prefer hybrid strategies, the compatible liquid gasket for oil pan products help address minor flange irregularities, while avoiding excessive squeeze-out that can clog pickup screens. Over the product life, buyers see ROI through:

- Lower oil consumption and reduced cleanup or top-off events.

- Improved customer satisfaction scores due to clean undercarriages and no driveway spots.

- Inventory efficiency via coverage-focused SKUs with stable lead times.

Feedback from auto parts distributors highlights decreased returns and improved installer confidence, attributing outcomes to robust bead design and clearly communicated torque guidelines.

Sustainability & Market Trends in automotive industry

Sustainability pressures in the automotive industry increasingly penalize fluid leaks and material waste. High-quality oil pan gasket solutions mitigate environmental risks by preventing oil drips that contaminate soil and water and by extending maintenance intervals. In parallel, lightweight carriers and optimized gasket profiles support OEM efforts to reduce mass without sacrificing sealing performance. Liquids and sealants are trending toward low-VOC, solvent-free formulations, aligning with global regulatory frameworks.

Market trends show rising demand for long-life sealing with compatibility across synthetic oils and aggressive additive packages—especially as turbocharging and start-stop cycles impose harsher thermal profiles. JULU YJM HWMF SEAL CO.,LTD. remains forward-thinking by:

- Prioritizing materials that balance heat resistance, elasticity, and chemical stability.

- Supporting quality systems and traceability expectations common to modern automotive supply chains.

- Collaborating with buyers on design-for-serviceability to reduce waste during maintenance.

As electrification advances, ICE platforms will continue to serve vast global fleets for years. Durable engine sump gasket solutions will remain essential to fleet uptime and environmental compliance—an area where JULU YJM HWMF SEAL CO.,LTD. invests in continuous improvement and application coverage.

Conclusion on oil pan gasket,pan gasket,engine sump gasket,liquid gasket for oil pan from JULU YJM HWMF SEAL CO.,LTD.

For B2B decision makers, a dependable oil pan gasket strategy reduces leak risk, protects brand reputation, and improves lifecycle cost across automotive industry / auto parts / Engine Parts portfolios. With engineered materials, precise bead designs, and proven fitment coverage—including liquid gasket for oil pan options—JULU YJM HWMF SEAL CO.,LTD. delivers the performance and consistency modern programs demand.

Contact us: email: yjm006@hwmf.com

Visit our website: https://www.yjmseal.com

-

Seal 12x20x5: Precision Radial Shaft Seals for Industrial Reliability

News Nov.24,2025

-

Seal 12x18x5: Essential Guide to Specifications, Applications & Vendors

News Nov.24,2025

-

Understanding Seal 12 20 5: Applications, Specifications & Industry Insights

News Nov.23,2025

-

Durable Oil Seal 85x110x12 – Reliable Sealing Solutions for Industry

News Nov.23,2025

-

Durable and Precise Oil Seal 75x95x10 for Efficient Machinery | YJM Seal

News Nov.22,2025

-

Durable Oil Seal 75x100x10 for Reliable Industrial Performance | YJM Seal

News Nov.22,2025

-

High-Quality Oil Seal 65x90x10 | Durable & Reliable Sealing Solutions

News Nov.22,2025

Products categories