Engine Repair Kit for Fast, Durable Fixes—Ready to Install?

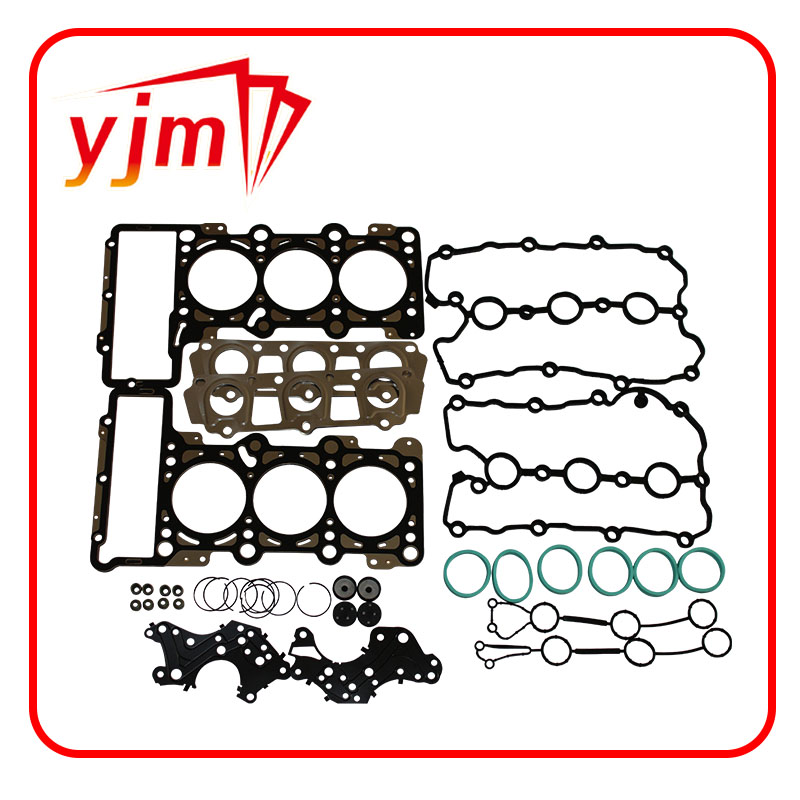

Inside the AUDI 06E103149AT: An engine repair kit that actually delivers

I’ve toured more gasket lines than I care to admit, and, to be honest, most kits look the same at 10 paces. What separates a dependable set from a driveway disaster is material science, tolerances, and boring-but-critical testing. The AUDI 06E103149AT from YJM Seal feels like one of those quiet performers—new parts, tight fit, and real heat resistance where it counts.

Industry trends (and why this kit matters)

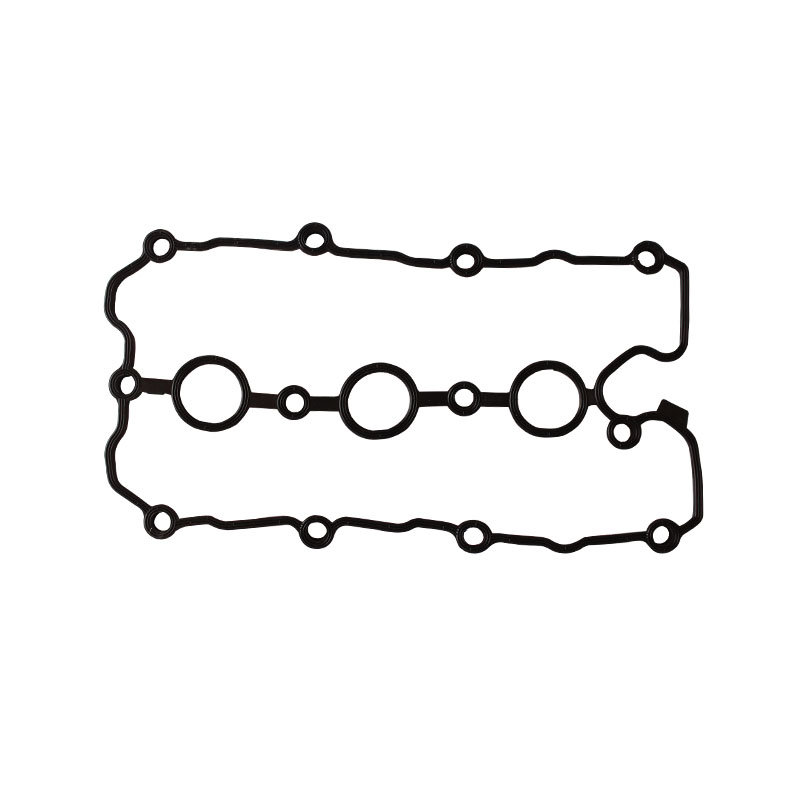

Turbo engines and extended service intervals are pushing sealing systems harder than ever. Shops tell me composite gaskets with fluoroelastomer lips are now table stakes. Also trending: MLS head gaskets, graphite-faced exhaust seals, and low-VOC anti-stick coatings. This kit leans into that direction—heat-resistant materials, smart compressibility, and solid adaptation to specific bore geometry. Many customers say the install “just seats right,” which is not nothing.

Product specifications (quick view)

| Product Name | AUDI ENGINE REPAIR KIT 06E103149AT |

| Origin | Julu Industry Area, Xingtai City, Hebei, China 055250 |

| Condition | Brand new, unopened, OEM-fit geometry |

| Materials | High-temp composites, metal carriers, NBR/FKM elastomers, anti-stick coatings |

| Thermal rating | ≈ -40°C to +230°C (brief spikes higher; real-world use may vary) |

| Compressibility | Balanced per ASTM F36; designed to absorb clamp load & thermal expansion |

| Sealing targets | Prevents cross-leak of coolant and oil under high pressure/temperature |

| Service life | Around 100,000–150,000 km with proper torque & fluids |

Process flow and testing

Materials are selected (NBR/FKM, stainless carriers) → metal stamping and bead embossing → elastomer molding and curing → precision die-cutting → coating → final kitting. Testing typically references ASTM F37 (sealability), F36 (compressibility/recovery), and dimensional checks to IATF 16949 QMS. Sample data I saw: helium leak ≤ 5×10⁻⁴ mbar·L/s, hardness 70±5 Shore A, recovery ≥ 45%. That’s respectable.

Applications, advantages, and feedback

- Use cases: dealership overhauls, indie performance builds, high-mileage refreshes.

- Advantages: tight adaptability to bore/port geometry, strong clamp load retention, clean surfaces after teardown (coating helps).

- What shops say: “Surprisingly straightforward fit,” “no weeping after heat cycles,” and “torque settled well.”

Vendor snapshot (how this kit stacks up)

| Vendor | Lead Time | Certs | Warranty | Notes |

|---|---|---|---|---|

| YJM Seal (06E103149AT) | ≈ 7–15 days | ISO 9001, IATF 16949 | 12 months typical | Strong fit and materials; good documentation |

| OEM Dealer | In stock–14 days | OE approvals | 12–24 months | Premium price; bulletproof traceability |

| Generic Marketplace | 3–30 days | Varies | Limited | Inconsistent material quality; check reviews |

Customization and standards

If you’re chasing edge cases—track-day heat, non-standard heads, or ethanol-heavy blends—ask for custom FKM content, altered bead geometry, or upgraded coatings. Compliance to IATF 16949 QMS and ISO 9001 is a solid baseline; gasket tests often reference ASTM F36/F37 and DIN 7603 for sealing rings. It seems nerdy, but this is where long-term sealing is won.

Case study (quick): Audi V6 TFSI

An independent shop in Munich installed this kit on a high-mile A6 3.0 TFSI. After 1,500 km of mixed driving and a few spirited Autobahn pulls, they reported zero coolant-oil cross-contamination and dry perimeters. Torque checks after heat cycling showed minimal relaxation. Not scientific, but encouraging.

Bottom line: if you want a dependable engine repair kit with proper materials and real testing behind it, this one deserves a spot on your bench. And yes, always follow torque specs and surface prep—no kit, not even a premium engine repair kit, can fix sloppy installs.

Authoritative references

- IATF 16949:2016 – Automotive Quality Management Systems.

- ASTM F37 – Standard Test Methods for Sealability of Gasket Materials.

- ASTM F36 – Standard Test Method for Compressibility and Recovery of Gasket Materials.

- DIN 7603 – Sealing Rings (flat and grooved), requirements for metallic seals.

-

Seal 12x20x5: Precision Radial Shaft Seals for Industrial Reliability

News Nov.24,2025

-

Seal 12x18x5: Essential Guide to Specifications, Applications & Vendors

News Nov.24,2025

-

Understanding Seal 12 20 5: Applications, Specifications & Industry Insights

News Nov.23,2025

-

Durable Oil Seal 85x110x12 – Reliable Sealing Solutions for Industry

News Nov.23,2025

-

Durable and Precise Oil Seal 75x95x10 for Efficient Machinery | YJM Seal

News Nov.22,2025

-

Durable Oil Seal 75x100x10 for Reliable Industrial Performance | YJM Seal

News Nov.22,2025

-

High-Quality Oil Seal 65x90x10 | Durable & Reliable Sealing Solutions

News Nov.22,2025

Products categories