Looking for a transmission oil pan gasket that won't leak?

transmission oil pan gasket,oil pan drain plug gasket,pan gasket,oil pan gasket is a key solution in the automotive industry, specifically within Automotive parts manufacturing and Engine Parts. This article explores how JULU YJM HWMF SEAL CO.,LTD. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- transmission oil pan gasket,oil pan drain plug gasket,pan gasket,oil pan gasket Overview

- Benefits & Use Cases of transmission oil pan gasket,oil pan drain plug gasket,pan gasket,oil pan gasket in Engine Parts

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in automotive industry

- Conclusion on transmission oil pan gasket,oil pan drain plug gasket,pan gasket,oil pan gasket from JULU YJM HWMF SEAL CO.,LTD.

transmission oil pan gasket,oil pan drain plug gasket,pan gasket,oil pan gasket Overview

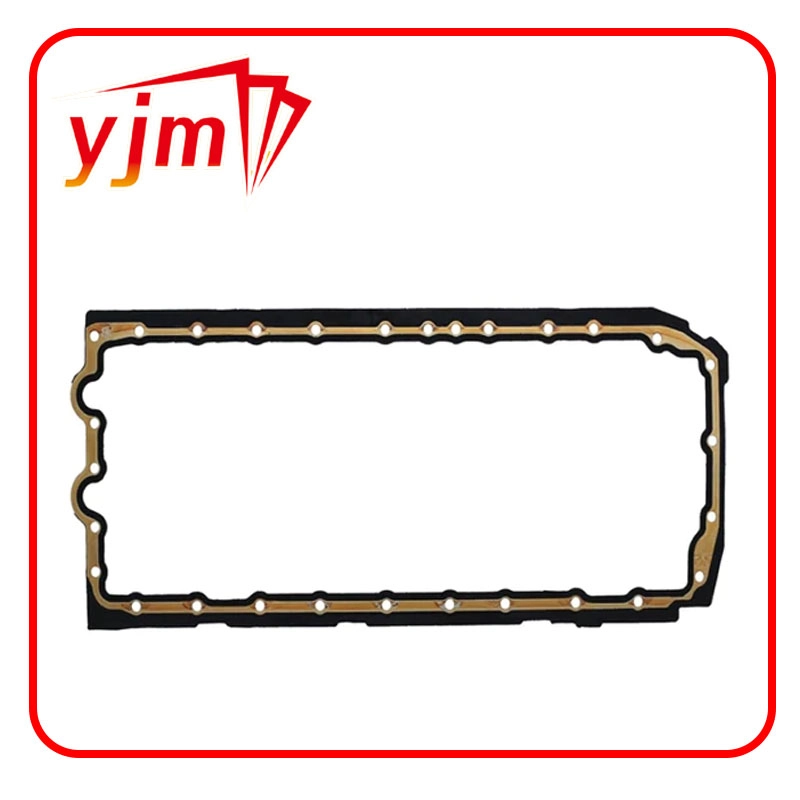

In powertrain sealing, few components impact uptime and warranty metrics as directly as the oil pan gasket and transmission pan interface. A high-quality transmission oil pan gasket or engine oil pan gasket provides a conformal, fluid-tight barrier between the pan and the mating surface, preventing leaks of ATF or engine oil under thermal cycling, vibration, and bolt-load relaxation. Likewise, an oil pan drain plug gasket ensures repeatable sealing at service intervals, minimizing drips and contamination risk.

JULU YJM HWMF SEAL CO.,LTD. manufactures precision pan gasket solutions using application-appropriate polymers and carriers, including NBR, HNBR, and FKM elastomers, cork-rubber composites, and steel-reinforced rubber carriers. Typical performance targets include compatibility with modern low-SAPS lubricants and ATFs, compression set resistance for long-term clamping, and heat tolerance suitable for underbody thermal profiles. Molded-in sealing beads and rigid carriers help maintain uniform stress distribution, reducing the need for RTV and cutting installation time. For B2B buyers, the company’s consistent tooling and material controls enable stable quality across volumes and SKUs, aligning with OEM and aftermarket expectations for fit, finish, and durability. Explore the representative product page here: https://www.yjmseal.com/yjm-oil-sump-gasket-11-13-7-600-482.html.

Benefits & Use Cases of transmission oil pan gasket,oil pan drain plug gasket,pan gasket,oil pan gasket in Engine Parts

Across Engine Parts programs, transmission oil pan gaskets and engine pan gaskets are specified for new assembly, remanufacturing, and service kits. Applications span passenger vehicles, light commercial, and off-highway platforms where thermal cycling, chassis flex, and fluid chemistry vary. An oil pan drain plug gasket—often an aluminum, copper, or engineered polymer crush washer—delivers consistent sealing during routine oil changes, reducing return visits and environmental cleanup.

JULU YJM HWMF SEAL CO.,LTD. focuses on features B2B decision-makers value: precise flange conformity, bead geometry that compensates for surface irregularities, and materials matched to lubricant additives and temperature windows. For pan gasket programs, options include steel-core rubber to minimize creep, molded locator tabs for assembly accuracy, and surface finishes that enhance micro-sealing without over-torquing. These advantages translate into reduced seepage, fewer NVH-related callbacks linked to loose fasteners, and improved first-time-through rates on the line. The company’s application engineering helps distributors and OEMs rationalize SKU counts while maintaining coverage, streamlining inventory and improving turns—especially beneficial for private-label or kit bundling initiatives.

Cost, Maintenance & User Experience

Total cost of ownership in sealing is driven by more than purchase price. A robust oil pan gasket or transmission pan gasket lowers lifetime cost by preventing fluid loss, safeguarding catalytic systems, and avoiding corrosion at fastener points. Reductions in rework and warranty claims often outweigh small differences in component cost. For service operations, a correct-fit oil pan drain plug gasket prevents come-backs caused by weeping plugs after oil changes—saving labor hours and customer goodwill.

B2B customers report that consistent clamping behavior and clear orientation features speed up installs and reduce technician variability. For maintenance best practices, ensure clean mating surfaces, follow the OEM torque sequence and specs, and avoid over-application of RTV unless required by the service manual. With JULU YJM HWMF SEAL CO.,LTD., buyers benefit from stable lead times, predictable quality across batches, and packaging options that protect sealing surfaces in transit. The result is improved ROI via higher throughput, less scrap, and a tighter feedback loop from field performance to procurement planning.

Sustainability & Market Trends in automotive industry

As powertrains evolve, sealing materials must keep pace with low-viscosity oils, bio-based additives, and higher thermal loads around turbocharged and hybrid systems. Pan gasket and drain plug gasket designs increasingly emphasize lightweight carriers, reduced VOC bonding processes, and materials that maintain integrity with modern ATF and engine oil chemistries. Regulatory attention on fluid leaks is intensifying; minimizing drips supports plant ESG metrics and dealer service compliance while protecting groundwater and shop environments.

JULU YJM HWMF SEAL CO.,LTD. aligns product development with these shifts—prioritizing material compatibility, long-life compression set performance, and manufacturability that curbs waste. Engineering efforts center on durability under extended service intervals, contributing to fewer replacements and less packaging and transport emissions over a vehicle’s life. Market trends also include the growth of hybrid transmissions and sealed-for-life assemblies; where serviceable, precision pan gaskets remain critical. By pairing application-driven materials with efficient production and robust QC, the company positions customers to meet performance targets and sustainability objectives simultaneously.

Conclusion on transmission oil pan gasket,oil pan drain plug gasket,pan gasket,oil pan gasket from JULU YJM HWMF SEAL CO.,LTD.

For Engine Parts programs, selecting the right transmission oil pan gasket, oil pan gasket, and oil pan drain plug gasket directly impacts reliability, service efficiency, and operating costs. JULU YJM HWMF SEAL CO.,LTD. delivers fit-for-purpose pan gasket solutions engineered for durable sealing, consistent installation, and compatibility with contemporary lubricant chemistries. Partnering with a focused sealing manufacturer helps B2B buyers stabilize quality, simplify inventory, and protect margins.

Contact us: email: yjm006@hwmf.com

Visit our website: https://www.yjmseal.com

-

Seal 12x20x5: Precision Radial Shaft Seals for Industrial Reliability

News Nov.24,2025

-

Seal 12x18x5: Essential Guide to Specifications, Applications & Vendors

News Nov.24,2025

-

Understanding Seal 12 20 5: Applications, Specifications & Industry Insights

News Nov.23,2025

-

Durable Oil Seal 85x110x12 – Reliable Sealing Solutions for Industry

News Nov.23,2025

-

Durable and Precise Oil Seal 75x95x10 for Efficient Machinery | YJM Seal

News Nov.22,2025

-

Durable Oil Seal 75x100x10 for Reliable Industrial Performance | YJM Seal

News Nov.22,2025

-

High-Quality Oil Seal 65x90x10 | Durable & Reliable Sealing Solutions

News Nov.22,2025

Products categories