Engine Repair Kit for DIY & Pros—Complete, Durable, Easy?

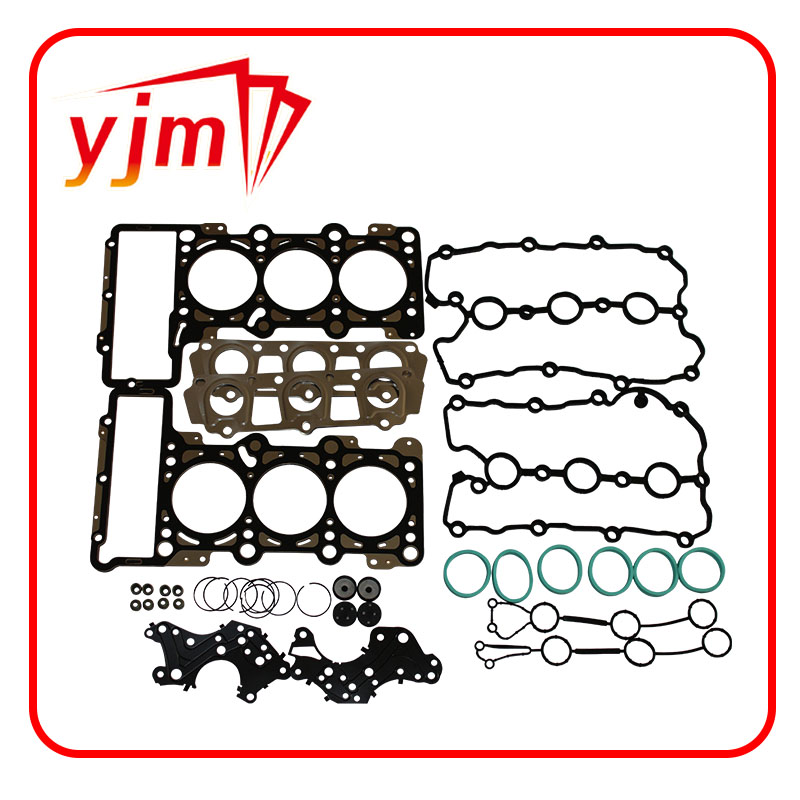

AUDI ENGINE REPAIR KIT 06E103149AT: field notes from a wrench-friendly journalist

If you’ve hunted for an engine repair kit lately, you’ve probably noticed two things: lots of lookalikes, and a painful spread in quality. This 06E103149AT set is one of those parts that, to be honest, either fixes the leak once—or makes you do the job twice.

What it is (and why shops keep it on hand)

The AUDI ENGINE REPAIR KIT 06E103149AT arrives new, sealed, and spec’d for reliable separation of coolant and lubricating oil—no cross-contamination, no weeping edges. Materials are chosen for heat and pressure: metal carriers, rubber (often FKM/NBR), and composite layers that retain torque and conform to micro-roughness. It’s built to compress just enough—then hold.

Quick spec sheet (shop-counter edition)

| Model | AUDI ENGINE REPAIR KIT 06E103149AT |

| Condition | New, unopened retail packaging |

| Materials | Metal carriers, rubber (FKM/NBR), fiber-composite |

| Operating temp | ≈ -40°C to +230°C (real-world use may vary) |

| Seal media | Engine oil, coolant, blow-by gases |

| Compression set | ≤ 25% @ 150°C, 22h (ASTM D395) |

| Leakage | ≤ 0.1 cc/min @ 1 bar (ASTM F37 bench) |

| Service life | Up to 150,000–200,000 km with proper torque & fluids |

| Certifications | ISO 9001, IATF 16949 compliant production |

| Origin | Julu Industry Area, Xingtai City, Hebei, China 055250 |

Manufacturing and test flow (how it earns its keep)

Materials: heat-resistant metal carriers; elastomers per ASTM D2000; bead/coating tuned for micro-seal. Methods: precision stamping, CNC die-cutting, vulcanization, PTFE or FKM bead application, batch curing. Testing: dimensional CMM checks; sealability per ASTM F37; compression set per ASTM D395; thermal cycling -40°C↔200°C for ≈500 cycles; surface energy/adhesion; torque retention loops (50–100 repeats). Documentation: PPAP-ready, lot traceability. Frankly, it’s more lab time than most people expect for a gasket set.

Where it fits and how shops use it

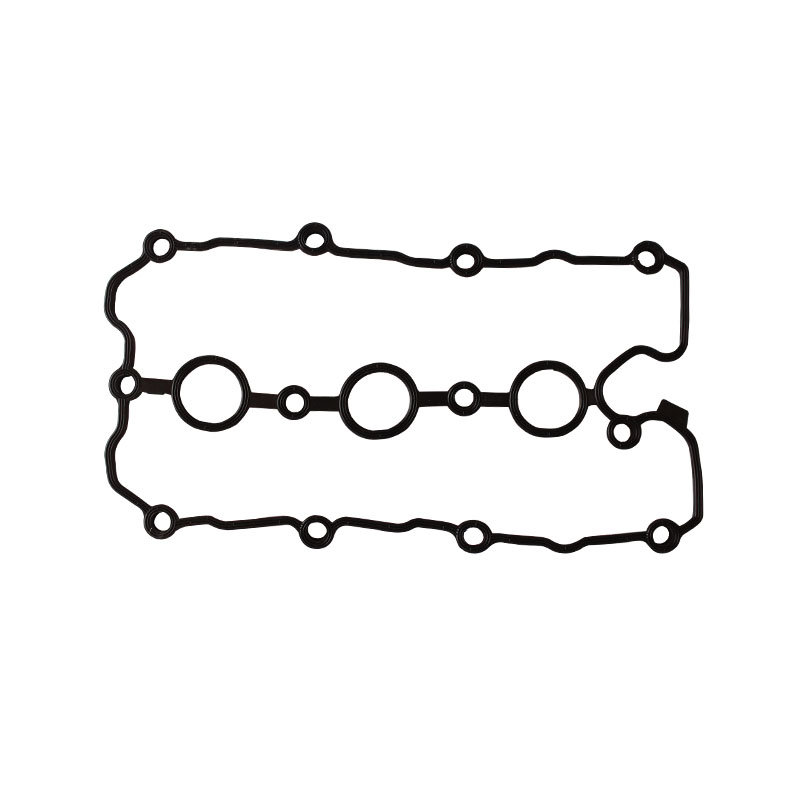

Typical use: Audi 06E-series engines where 06E103149AT applies—always verify by VIN. Common jobs include resealing cam/cover areas, coolant junctions, and interfaces that see mixed oil/coolant exposure. Many customers say the set “just fits”—no trimming, no drama, which is nice.

Engine repair kit advantages: quick turnaround; compressibility that tracks thermal expansion; high-temp stability; coatings that resist stick-slip during torque checks.

Vendor comparison (what buyers quietly ask me)

| Vendor | Lead Time | Certs | Customization | Typical Price |

|---|---|---|---|---|

| Factory (YJM Seal) | ≈7–15 days | ISO 9001, IATF 16949 | Thickness, elastomer, bead | Mid |

| OEM Dealer | In stock/region-dependent | OEM supply chain | Limited | High |

| Generic Aftermarket | 2–30 days | Varies | Varies | Low |

Customization options (when “stock” isn’t quite right)

For fleets or tuners: alternate elastomer (FKM for sustained heat), bead height tweaks for warped covers, anti-stick coatings, and thickness tuning for torque windows. I guess that’s overkill for daily drivers—but performance shops love it.

Case notes from the field

Case A: Independent Audi specialist resealed a high-mileage V6; post-job leak test: 0 cc/min at 1 bar; comeback rate: zero after 6 months. Owner comment: “No more driveway spots.”

Case B: Fleet service (ride-hail) standardized this engine repair kit; downtime per car dropped ≈18% thanks to first-pass fit and fewer torque rechecks.

Final checks before you order

- Confirm 06E103149AT applicability by VIN/supersession.

- Follow torque specs and pattern—thermal cycles matter.

- Use OE-grade fluids; re-torque after initial heat soak if specified.

In short, this engine repair kit is built for real-world bays, not just brochure specs. And that, surprisingly, still isn’t universal.

Authoritative citations

-

Seal 12x20x5: Precision Radial Shaft Seals for Industrial Reliability

News Nov.24,2025

-

Seal 12x18x5: Essential Guide to Specifications, Applications & Vendors

News Nov.24,2025

-

Understanding Seal 12 20 5: Applications, Specifications & Industry Insights

News Nov.23,2025

-

Durable Oil Seal 85x110x12 – Reliable Sealing Solutions for Industry

News Nov.23,2025

-

Durable and Precise Oil Seal 75x95x10 for Efficient Machinery | YJM Seal

News Nov.22,2025

-

Durable Oil Seal 75x100x10 for Reliable Industrial Performance | YJM Seal

News Nov.22,2025

-

High-Quality Oil Seal 65x90x10 | Durable & Reliable Sealing Solutions

News Nov.22,2025

Products categories