Understanding Semi Truck Axle Seals and Their Importance in Vehicle Maintenance

Understanding Semi Truck Axle Seals Importance and Maintenance

Semi trucks are the backbone of freight transportation, playing a crucial role in the logistics and supply chain industries. Among the myriad of components that ensure these vehicles operate smoothly, axle seals often remain underappreciated. Nevertheless, they are vital for the longevity and efficiency of semi trucks. This article explores the importance of semi truck axle seals, their function, and maintenance tips to ensure their optimal performance.

The Function of Axle Seals

Axle seals are integral components located at the junction where the axle shaft exits the axle housing. Their primary role is to prevent the leakage of lubricant from the axle while also keeping dirt, grime, and moisture from entering the axle assembly. Given the heavy loads that semi trucks carry, adequate lubrication is essential for the proper functioning of differential gears and bearings. Axle seals help maintain the right oil levels, thus preventing premature wear and tear on these components.

In essence, axle seals serve as a protective barrier. Without these seals, the lubricant would gradually leak out, leading to insufficient lubrication, increased friction, and ultimately, significant damage to axle components. This can result in costly repairs and downtime, which every truck operator strives to avoid.

Signs of Damaged Axle Seals

Identifying problems with axle seals early can save truck operators from extensive repair costs. There are several warning signs that indicate axle seal failure

1. Fluid Leaks One of the most common indicators of a failing seal is the presence of oil on the ground beneath the truck. If you notice any fluid pooling beneath the rear axle, it's crucial to investigate further.

3. Temperature Increases An increase in axle temperature can point to insufficient lubrication due to seal failure. Using a temperature gauge can help monitor this.

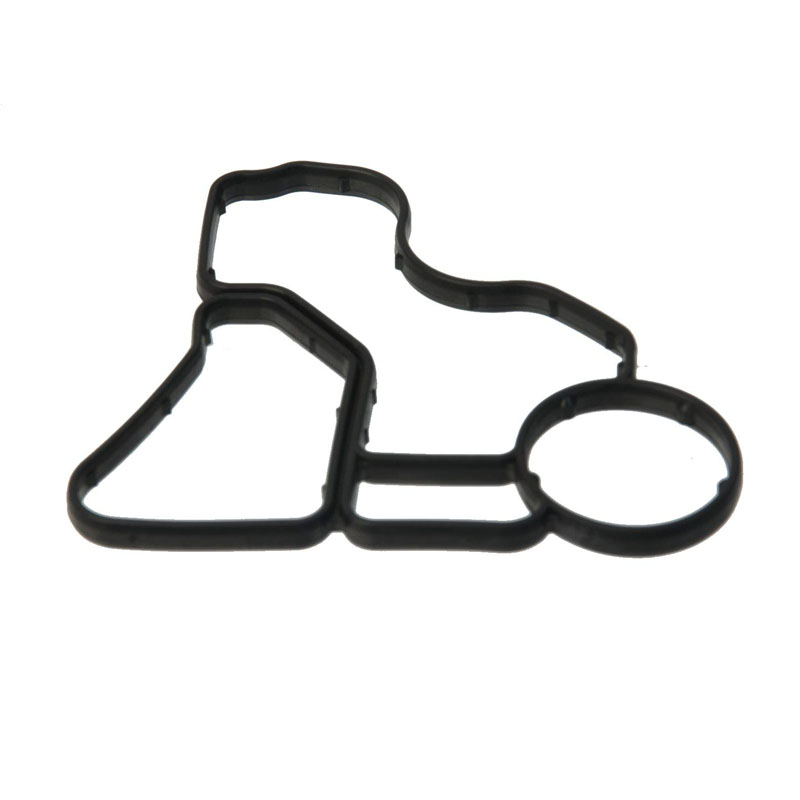

semi truck axle seal

4. Visual Damage Any visible cracks, tears, or degradation in the seals themselves can also indicate that they need to be replaced.

Maintenance Tips

Maintaining semi truck axle seals is essential in extending their lifespan and ensuring the safe operation of the vehicle. Here are some maintenance tips to consider

- Regular Inspections Schedule routine inspections of your semi truck’s axle assemblies. Look for signs of wear and tear on the seals, and check for any fluid leaks.

- Check Lubricant Levels Regularly check the lubricant levels and replace them according to the manufacturer’s recommendations. Low lubricant levels can place excessive strain on the axle seals.

- Use Quality Parts When replacing axle seals, always opt for high-quality parts that meet or exceed OEM specifications. Quality seals are designed to withstand the rigors of heavy-duty operations.

- Professional Servicing Whenever there’s a doubt about the integrity of the axle seals, consulting a professional mechanic is advisable. Their expertise can help prevent minor issues from escalating into significant and costly repairs.

Conclusion

Semi truck axle seals may be small in size, but their impact on the overall performance and reliability of the vehicle is enormous. Properly functioning axle seals ensure that the truck operates efficiently, preventing costly repairs and downtime. As part of regular vehicle maintenance, monitoring and servicing axle seals will ultimately contribute to the longevity and safety of your semi truck on the road. Being proactive about maintenance can save truck operators time and money while ensuring that they continue to meet the demands of the logistics industry.

-

Understanding Different Types of Oil Drain Plugs: A Comprehensive Guide

News Jun.27,2025

-

The Role of Nylon Washers in Oil Drain Maintenance: A Practical Guide

News Jun.27,2025

-

The Essential Guide to Drain Plug Washers: Types, Uses, and Best Practices

News Jun.27,2025

-

Everything You Need to Know About Washer and Plug Sealing: Polaris-Specific and General Tips

News Jun.27,2025

-

A Comprehensive Guide to Different Types of Oil Drain Plugs for Efficient Maintenance

News Jun.27,2025

-

A Complete Guide to Oil Drain Plug Washers: Tridon and Euro Car Parts Solutions

News Jun.27,2025

-

Understanding Oil Drain Plugs: Types, Issues, and Replacements

News Jun.26,2025

Products categories