oil seal 12 20 5

The Fundamentals of Oil Seals Understanding the 12-20-5 Specification

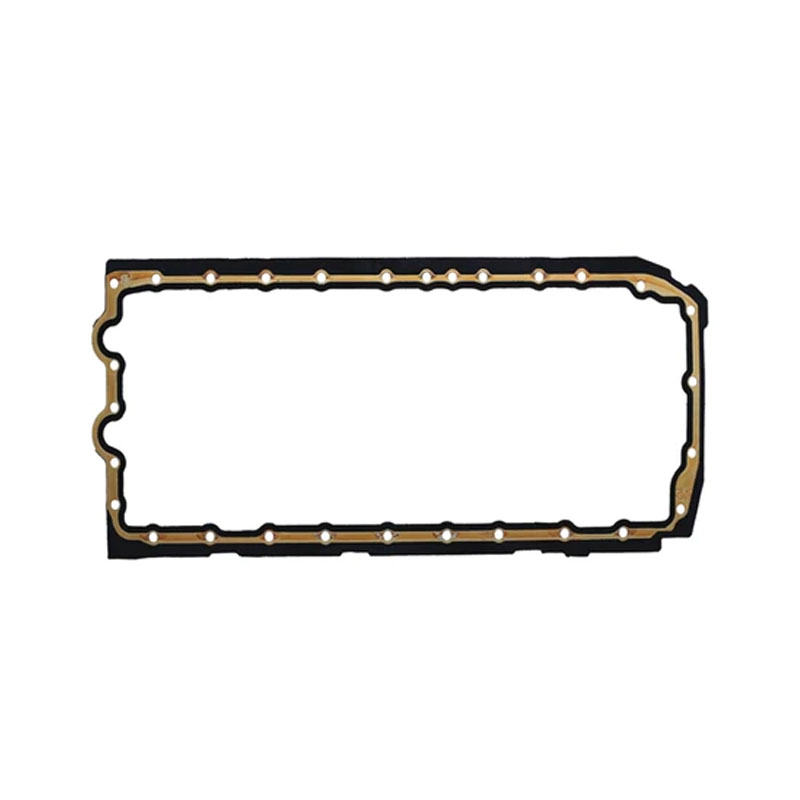

Oil seals are essential components in many mechanical systems, designed primarily to prevent the leakage of lubricants and the ingress of contaminants. They serve a pivotal role in ensuring the longevity and efficiency of machinery. The designation “12 20 5” referring to an oil seal, provides key information regarding its dimensions, materials, and applications.

What Do the Numbers Mean?

The numbers in the specification can generally be interpreted as follows - The first number (12) represents the inner diameter of the seal in millimeters. This dimension is critical as it indicates the size of the shaft or component the seal is meant to fit. - The second number (20) refers to the outer diameter, also in millimeters. It is equally important since it helps to determine the amount of space the seal will occupy within a housing or casing. - The last number (5) indicates the thickness or cross-section of the seal. A thicker seal may provide a better sealing surface, but it must still fit adequately within the design constraints of the equipment.

This standardized nomenclature is crucial for manufacturers and engineers when sourcing or designing seals for their specific applications.

The Importance of Material Selection

The choice of material for an oil seal is pivotal. Common materials include rubber compounds, thermoplastics, and metals, each offering different advantages. For instance, Nitrile rubber (NBR) is frequently used for oil seals because of its excellent resistance to petroleum-based oils and its ability to perform at various temperatures. Fluoroelastomers (FKM) may be used in applications that require enhanced chemical and thermal resistance.

Additionally, the operating environment plays a crucial role in material selection. For example, seals used in food processing equipment will have stringent regulations regarding materials to ensure they are safe and non-toxic, often requiring FDA-approved materials.

oil seal 12 20 5

Designing for Efficiency and Longevity

When designing an oil seal, it is not just about fitting the numbers; factors such as the speed of the shaft, temperature, and pressure must also be considered. The seal’s lip design plays a crucial role in its performance. A well-designed lip can create a hydraulic seal that withstands high pressures and prevents leakage effectively.

Furthermore, proper installation is critical. An incorrectly installed seal can lead to premature failure, causing costly repairs and downtime. Engineers must ensure concentricity, alignment, and cleanliness during installation to guarantee optimal performance.

Applications of Oil Seals

Oil seals are ubiquitous in various industries. They are found in automotive applications, such as in engines, transmissions, and axles, where they keep lubricants in and dirt out. In industrial machinery, oil seals are essential in pump housings, gearboxes, and compressors, where they contribute to the efficiency and reliability of the system.

Additionally, they find applications in household appliances and machinery, highlighting their versatility. As technology progresses and industry standards evolve, the demand for high-performance seals continues to grow, pushing manufacturers to innovate in materials and designs.

Conclusion

Understanding the significance of oil seals, especially those conforming to specific dimensions like the 12-20-5 specification, is fundamental for professionals working in mechanical engineering, manufacturing, and maintenance. The interplay between design, material choice, and application not only impacts the efficacy of the seal but also influences the entire system's reliability and efficiency. As industries strive for higher performance and sustainability, the role of oil seals in maintaining equipment integrity and preventing leakage becomes increasingly vital. Continuous advancements in seal technology promise to enhance performance and expand the potential applications of these indispensable components. Whether in an automobile, industrial machinery, or consumer products, oil seals remain a crucial element of modern engineering.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories