mechanical oil seal types

Understanding Mechanical Oil Seal Types An Overview

Mechanical oil seals are essential components in various machinery and equipment, serving the primary purpose of preventing the leakage of lubricants or other fluids and protecting the interior of machines from external contaminants. They play a critical role in enhancing the durability and efficiency of mechanical systems. With a myriad of designs and types available, understanding the various mechanical oil seal types is crucial for selecting the right one for specific applications.

1. Static Seals vs. Dynamic Seals

Oil seals can primarily be categorized into static and dynamic seals. Static seals are used in applications where there is little to no movement between the sealing surfaces. They are often employed in applications like flanges and housing interfaces. Dynamic seals, on the other hand, are used where there is relative motion between the components, such as in rotating shafts. The performance and lifespan of a seal are heavily influenced by its type and application.

2. Common Types of Mechanical Oil Seals

- Rubber Oil Seals One of the most common types, these seals are made from various elastomeric materials. They offer excellent flexibility and can conform to irregular surfaces. Rubber oil seals are often used in automotive and industrial applications due to their resistance to wear, aging, and environmental factors.

- Lip Seals These seals consist of a flexible lip that makes contact with the rotating shaft. The design allows for effective sealing against oil and other fluids while accommodating some shaft misalignment. Lip seals are commonly used in bearings and various machinery where fluid retention is necessary.

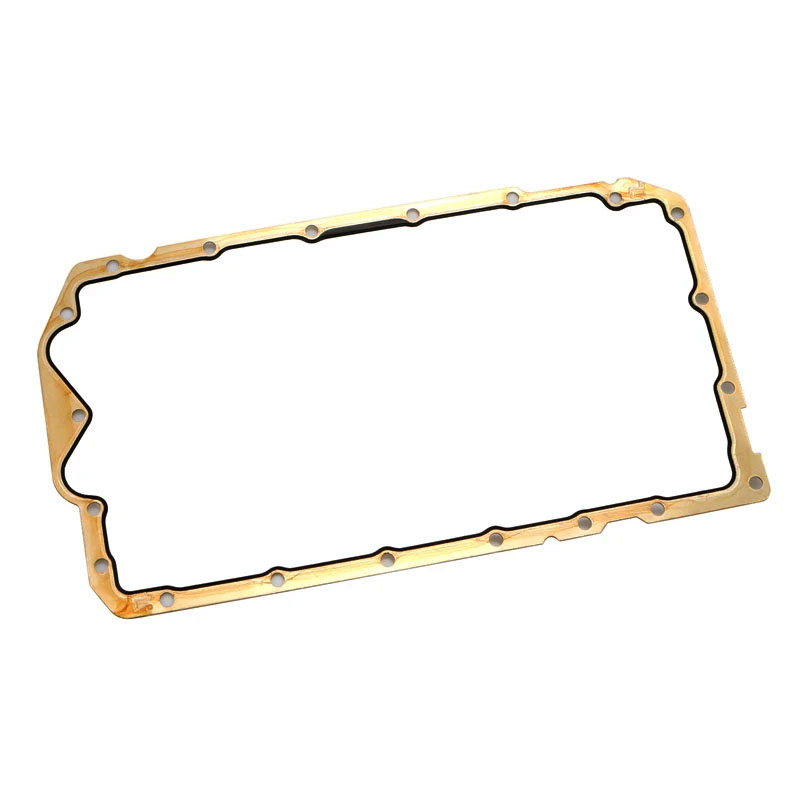

- Metal-Casing Seals Featuring a rigid metal case, these seals provide additional strength and are suitable for high-pressure applications. They typically include a sealing lip made from rubber or elastomer, ensuring a tight fit around the shaft. Metal-casing seals are commonly used in heavy machinery and automotive applications.

- Composite Seals Combining different materials, composite seals offer enhanced properties such as resistance to extreme temperatures and chemicals. They are particularly beneficial in industries that face harsh environmental conditions, like oil and gas or chemical processing.

mechanical oil seal types

- Teflon Seals Known for their excellent chemical resistance and low friction properties, Teflon seals are ideal for applications that require minimal wear and tear. These seals are commonly used in industries dealing with aggressive fluids and high temperatures.

3. Selection Criteria

When choosing the appropriate oil seal type for a specific application, several factors must be considered

- Operating Conditions The temperature, pressure, and type of fluid being sealed can dictate the most suitable seal material and design. For instance, high-temperature applications may require seals made from specialized materials like silicone or Teflon.

- Shaft Speed Higher rotational speeds can affect seal performance. Dynamic seals need to be selected with care to ensure they can handle the friction and heat generated at higher speeds.

- Compatibility The seal material should be compatible with the lubricants and fluids they will contact, preventing chemical degradation that could lead to seal failure.

- Installation and Space Restrictions Some designs may require more space for installation, while others may offer more flexibility in tight spaces. It's crucial to consider these factors during the selection process.

Conclusion

Mechanical oil seals are vital components that contribute significantly to the efficiency and lifespan of machinery. Understanding the different types of oil seals and their respective applications allows engineers and maintenance professionals to make informed decisions, thus ensuring optimal performance. By considering the operating conditions, compatibility, and specific needs of the application, the right seal can be chosen, leading to enhanced reliability and reduced maintenance costs in the long run.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories