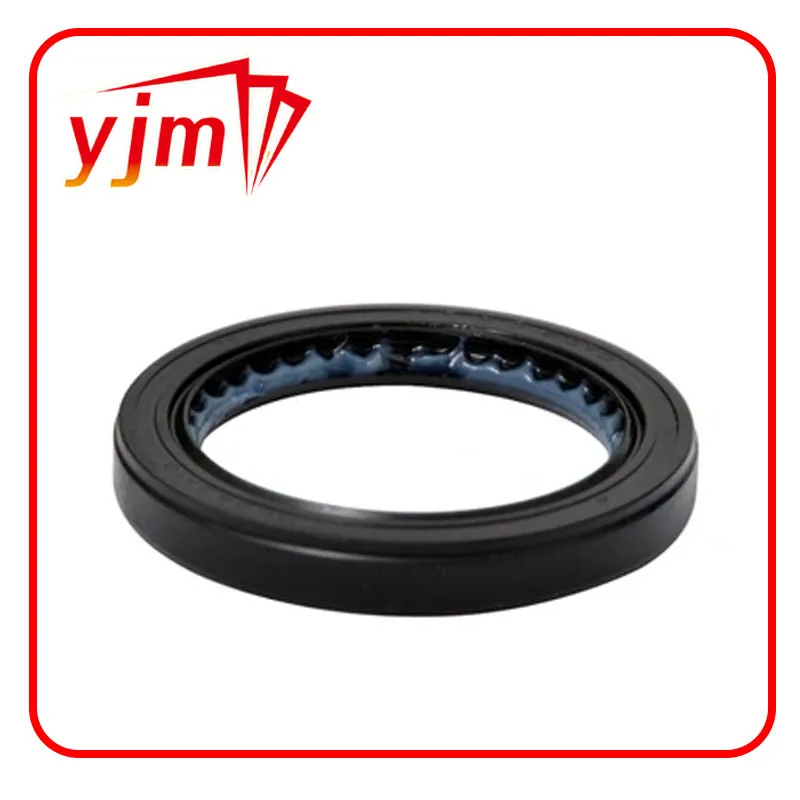

garter spring seal

The Garter Spring Seal A Comprehensive Overview

The garter spring seal, a vital component in the realm of mechanical engineering and sealing technology, represents an innovative approach to creating reliable seals in various industrial applications. Designed to prevent fluid or gas leaks, the garter spring seal offers both versatility and efficiency, making it a preferred choice in a wide range of industries, including automotive, aerospace, and manufacturing.

At its core, the garter spring seal consists of a flexible elastomeric material molded into a specific shape, often in the form of a ring. The defining feature of this seal is its embedded garter spring, which exerts constant radial pressure against the outer wall of the housing and the inner wall of the bore. This active application of force ensures that the seal maintains contact with both surfaces, thereby effectively preventing the escape of fluids or gases.

One of the essential advantages of the garter spring seal is its ability to adapt to variations in pressure and temperature. As operating conditions change, the garter spring compensates for any loss of sealing force due to wear or thermal expansion. This dynamic capability significantly enhances the lifespan of the seal, reducing the need for frequent maintenance or replacement. In high-pressure environments, this adaptability is especially critical, as it ensures a consistent barrier against leaks that could lead to catastrophic failures.

The material selection for garter spring seals is paramount in determining performance

. Commonly used elastomers include nitrile, fluorocarbon, and silicone, each chosen for its unique properties. Nitrile rubber, for instance, is well-suited for oil applications due to its excellent resistance to petroleum products. Meanwhile, fluorocarbon seals excel in high-temperature applications and provide outstanding chemical resistance. Silicone seals, on the other hand, are favored in environments that require high compressibility and flexibility while also being able to withstand extreme temperature fluctuations.garter spring seal

The design simplicity of the garter spring seal is another factor contributing to its popularity. Installation is straightforward, requiring minimal tooling and technical expertise. This ease of use translates to reduced labor costs and a faster implementation process, which is particularly advantageous in fast-paced industrial settings. Furthermore, the compact design of garter spring seals allows for their integration into tight spaces where traditional sealing solutions may not fit.

In addition to automotive and aerospace industries, garter spring seals find applications in diverse sectors such as food processing, pharmaceuticals, and chemical manufacturing. In these fields, where hygiene and safety are paramount, the seal's reliability in preventing contamination is crucial. The ability to customize the dimensions and material properties of garter spring seals makes them suitable for specialized applications, catering to the specific needs of each industry.

Despite their many advantages, garter spring seals are not without limitations. Over time, exposure to harsh environments or extreme temperatures can lead to material degradation, compromised sealing performance, or failure. Regular inspection and maintenance are essential to ensure that seals continue to function effectively, particularly in critical applications.

In conclusion, the garter spring seal is a marvel of engineering that provides a reliable means of sealing in a variety of applications. Its unique design, material versatility, and ability to adapt to changing conditions make it an indispensable element in many industries. As technology continues to advance, the ongoing development and optimization of garter spring seals promise to enhance their performance and expand their applications, further solidifying their position as a trusted sealing solution in the modern industrial landscape.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories