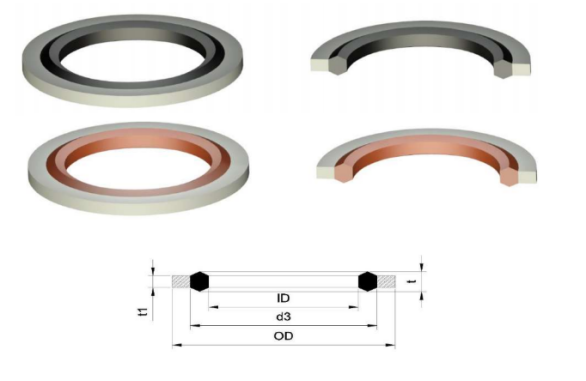

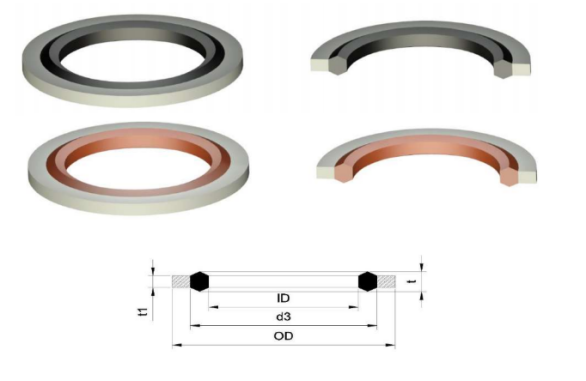

Select axle seals based on their size.

These catalogues include measurements such as inner diameter, outer diameter, and lip width, making it easier for mechanics and engineers to find the right fit These catalogues include measurements such as inner diameter, outer diameter, and lip width, making it easier for mechanics and engineers to find the right fit

These catalogues include measurements such as inner diameter, outer diameter, and lip width, making it easier for mechanics and engineers to find the right fit These catalogues include measurements such as inner diameter, outer diameter, and lip width, making it easier for mechanics and engineers to find the right fit axle seals by size. They also consider the material of the seal, which can range from rubber to polyurethane, each with its own advantages and suitable operating environments.

Innovations in seal technology have led to the development of seals with improved resistance to wear, heat, and chemicals. This not only enhances the lifespan of the seal but also reduces maintenance costs and potential downtime.

In conclusion, selecting the correct axle seals by size is a vital aspect of vehicle and machinery maintenance. It ensures optimal performance, prevents premature failure, and safeguards the integrity of the entire system. Therefore, whether you're a professional mechanic or a DIY enthusiast, understanding the significance of size in axle seals is crucial. Always refer to the manufacturer's guidelines or consult with experts to ensure the right seal is chosen for your specific application. After all, the right seal can make all the difference between a smooth ride and a potential breakdown.

axle seals by size. They also consider the material of the seal, which can range from rubber to polyurethane, each with its own advantages and suitable operating environments.

Innovations in seal technology have led to the development of seals with improved resistance to wear, heat, and chemicals. This not only enhances the lifespan of the seal but also reduces maintenance costs and potential downtime.

In conclusion, selecting the correct axle seals by size is a vital aspect of vehicle and machinery maintenance. It ensures optimal performance, prevents premature failure, and safeguards the integrity of the entire system. Therefore, whether you're a professional mechanic or a DIY enthusiast, understanding the significance of size in axle seals is crucial. Always refer to the manufacturer's guidelines or consult with experts to ensure the right seal is chosen for your specific application. After all, the right seal can make all the difference between a smooth ride and a potential breakdown. -

Understanding Shaft Oil Seals: Protection, Performance, and Marine Applications

News Jun.23,2025

-

Understanding Crankshaft Oil Seals: Types, Functions, and Common Issues

News Jun.23,2025

-

The Rear Crankshaft Seal: Function, Failure Signs, and Replacement Guide

News Jun.23,2025

-

Rotary Shaft Seals: Essential Components for Leak-Free Performance

News Jun.23,2025

-

Everything You Need to Know About Crank Oil Seals and Related Costs

News Jun.23,2025

-

A Complete Guide to Front Engine Oil Seals and Their Role in Engine Health

News Jun.23,2025

-

Understanding Polaris Front Differentials: Key Components for Off-Road Performance

News Jun.20,2025

Products categories