Thông số kỹ thuật

Shaft diameter: 0.500 to 14.000 inch,10 to 350 mm

Polymer Material Options: Nitrile Rubber(NBR, XNBR).Fluorocarbon Rubber(FKM,FPM)

Minimum operating Temperature: -40 °F

Maximum operatingTemperature: 400(204 C) °F

Maximum shaft Runout: 0.010"

Maximum shaft-to-Bore Misalignment: 0.010”

Maximum operating Pressure: 0 to 7 psi

Maximum surface Speed: 2000 to 3200 (10.2 to16.3 m/s) ft/min

Seal Type: Metal or rubber-covered metal seal casing

Chất liệu phốt trục: Cao su

Mục thông tin

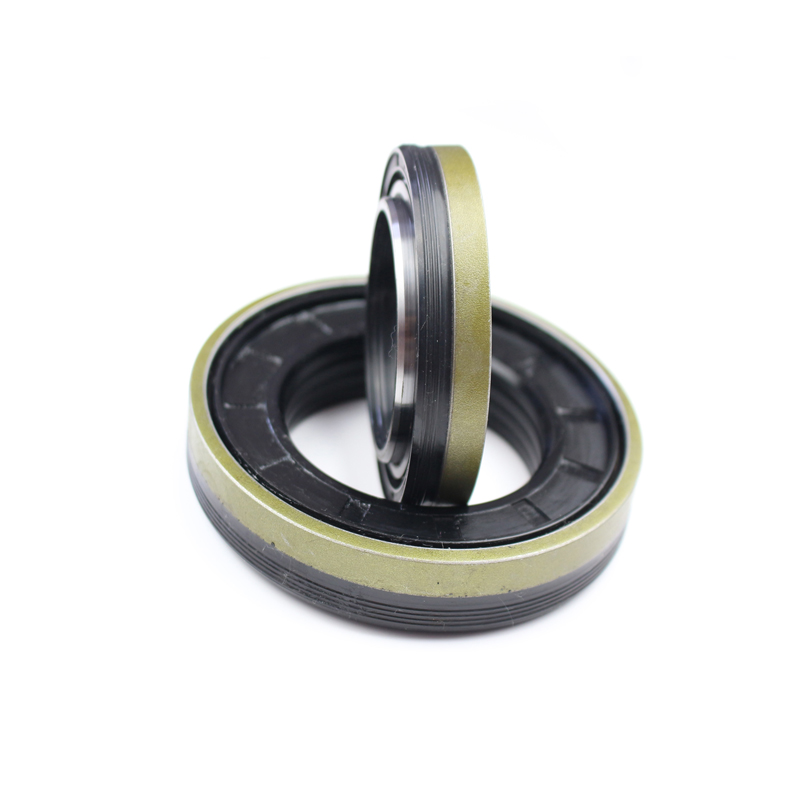

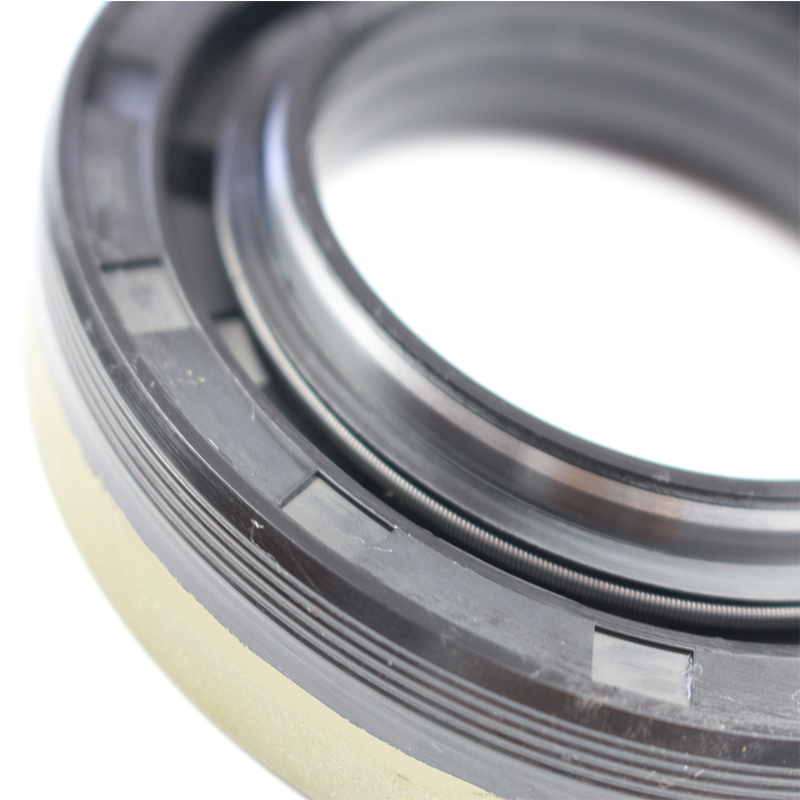

Phốt cassette (đôi khi được gọi là phốt trung tâm) mang lại độ tin cậy lâu dài trong các ứng dụng đòi hỏi khắt khe. Các phốt trục quay phức tạp này được sử dụng trong môi trường làm việc nặng nhọc để giữ chất lỏng và loại trừ các chất gây ô nhiễm khắc nghiệt. Với phương pháp kết cấu thống nhất, các bộ phận bịt kín chịu tải bằng lò xo nằm trên bề mặt ống bọc chống mòn bên trong khép kín. Nhiều điểm tiếp xúc bịt kín, cũng như các môi loại trừ có thể được tích hợp bên trong bề mặt ống bọc chống mòn và/hoặc nằm trên OD. Các thiết kế với vỏ OD bằng kim loại được bọc cao su giúp cải thiện độ kín chống lại lỗ khoan và được sử dụng cho vỏ hợp kim mềm.

Cassette seals from YJM are used in extreme conditions such as:

• Wash down applications on gear reducers used in food processing

• Mining, agriculture and power generation applications with severe environmental debris

YJM offers standard as well as custom cassette seal designs. Operating conditions and severity of the environment will dictate which design will meet your needs. Design options may include:

• Excluder lips for added protection against contamination and pollution, water spray and debris

• Patented axial face seal surface for dirt exclusion

• YJM sealant which fills small imperfections in the bore

• Rubber covered OD for improved sealing due to thermal expansion

Thiết kế tiêu chuẩn

CB Profile: Vỏ kim loại có keo dán lỗ khoan YJM tiêu chuẩn. Lưu ý: Thiết kế CB yêu cầu công cụ lắp đặt đặc biệt.

Cấu hình CL, CH: OD được bọc cao su để cải thiện khả năng bịt kín OD và vỏ bằng hợp kim mềm.

Các thiết kế tùy chỉnh có các điểm tiếp xúc loại trừ hoặc bịt kín bổ sung hoặc thay thế có thể được thiết kế cho các điều kiện đặc biệt như độ lệch cao, áp suất hoặc chuyển động dọc trục.

Phạm vi hoạt động điển hình cho thiết kế tiêu chuẩn

Chất liệu môi tiêu chuẩn:

NBR: Nhiệt độ -20F / +250F

FKM: Nhiệt độ -40F / +400F

Tốc độ bề mặt trục: Lên tới 3200 fpm (16,3 m/s) tùy theo áp suất

Áp suất tối đa: 0 đến 7 psi (0 đến 0,48 bar) tùy thuộc vào tốc độ trục

Phạm vi kích thước: 1/2 đến 14 inch (10 đến 350 mm)

Maximum Shaft Dynamic Runout (TIR): 0.010” (0.254 mm)

Maximum (STBM) Misalignment: 0.010” (0.254 mm)

Các ứng dụng tiêu biểu

Để sử dụng trong các dịch vụ khắc nghiệt cho các ứng dụng, hộp giảm tốc, hộp số, trục mô-men xoắn.

How do you install a cassette seal?

Installing a cassette seal is a precise process that requires careful handling to ensure optimal sealing performance and long-term durability, especially in heavy-duty applications such as agricultural machinery, trucks, and construction equipment. A cassette seal is an integrated sealing unit that includes multiple lip seals, a sleeve, and often a pre-lubricated cavity, designed to protect against contaminants like mud, dust, and water.

Before installation, proper preparation is essential. Begin by thoroughly cleaning the shaft and the bore where the seal will be installed. Remove any dirt, old sealant, rust, or burrs. Inspect the shaft for wear, scoring, or eccentricity, as these can lead to premature seal failure. If damage is found, repair or replace the shaft as needed. Ensure that all components are dry and free from oil before handling the new seal.

Lubrication is a critical step. If the cassette seal is not pre-lubricated, apply a thin film of compatible grease or oil to the sealing lips and the shaft surface. This helps to reduce friction during initial startup and prevents dry running. Be careful not to over-lubricate, as excess grease can cause pressure buildup.

During installation, align the cassette seal carefully with the shaft. Use a guide sleeve or plastic wrap over the shaft edges to avoid damaging the sealing lips. Press the seal evenly into the housing bore using an appropriate installation tool or press. Do not hammer directly on the seal, as this could cause distortion or misalignment. If using manual tools, apply force evenly around the outer ring.

Once the cassette seal is seated flush with the housing, double-check the alignment and ensure the seal is fully installed without any gaps or tilt. After installation, rotate the shaft by hand to check for smooth movement and proper fit. Finally, reassemble any removed components and test the equipment to ensure there are no leaks or unusual noises.

In summary, installing a cassette seal involves clean preparation, correct lubrication, careful alignment, and controlled pressing. Following these steps helps to ensure reliable sealing, reduce maintenance needs, and extend equipment service life.

What are cassette seals?

Cassette seals are advanced sealing solutions designed to provide superior protection in harsh and demanding environments. Commonly used in off-highway vehicles, agricultural machinery, construction equipment, and heavy trucks, cassette seals are ideal for applications where high contamination, extreme loads, or prolonged service life is required. Unlike traditional oil seals, cassette seals are more complex in design and function, offering multiple layers of protection.

A cassette seal consists of several components integrated into a single unit: multiple sealing lips, a metal or elastomeric outer case, and an inner sleeve or wear sleeve that interfaces with the shaft. The inner sleeve helps to protect the shaft from wear, while the sealing lips keep lubricants in and contaminants out. Often, these seals are pre-lubricated with grease to ensure immediate protection and to reduce friction during initial operation.

One of the key advantages of cassette seals is their excellent ability to resist the ingress of dirt, water, mud, and other abrasive particles. This is achieved through the use of multiple lip seals and often a labyrinth design that traps and redirects contaminants away from the sealing area. As a result, they significantly enhance the durability of the sealed components and reduce the frequency of maintenance and downtime.

Cassette seals are typically used in wheel hubs, axle assemblies, transmissions, and final drives. Because of their robust construction and ability to handle misalignment and shaft runout, they are favored in situations where traditional seals might fail prematurely.

In summary, cassette seals are high-performance sealing units designed for tough conditions. Their integrated design, multiple sealing layers, and contamination-resistant features make them essential in modern heavy-duty machinery, ensuring reliability, efficiency, and extended service life.

Cassette seals types

Cassette seals come in various types, each designed to meet the specific demands of different applications. These seals are commonly categorized based on their structure, the number of sealing lips, materials used, and the type of environmental protection they offer. Understanding the different types of cassette seals helps ensure optimal performance and longevity in heavy-duty applications such as tractors, trucks, construction machinery, and off-road vehicles.

One common type is the standard cassette seal, which includes a metal outer casing, an integrated wear sleeve, and multiple sealing lips—usually a primary lip to retain lubricant, secondary lips for dust exclusion, and sometimes a dirt exclusion lip. These seals are ideal for general-purpose use where both oil retention and dirt exclusion are necessary.

Another type is the heavy-duty cassette seal, which is designed for extreme environments involving high levels of mud, dust, or water exposure. These seals often feature reinforced lip structures, additional sealing elements like a labyrinth channel, and may come with pre-lubricated grease compartments. They are widely used in construction and agricultural machinery, especially in wheel-end applications.

The low-friction cassette seal is a variation that focuses on reducing energy loss due to friction between the sealing lips and the shaft. These are suitable for fuel-efficient systems where heat generation and power loss need to be minimized, such as in modern transmission systems and drivetrains.

There are also custom cassette seals, which are engineered for specific machinery or operating conditions. These can vary in dimensions, materials (e.g., Viton, NBR, or PTFE), and lip configurations, and are often used when standard solutions do not meet performance requirements.

In conclusion, cassette seals come in several types, each optimized for different performance needs—standard, heavy-duty, low-friction, and custom designs. Choosing the right type depends on factors such as load, speed, temperature, and contamination levels. Selecting the correct cassette seal type is crucial for achieving reliable sealing performance and minimizing equipment wear and downtime.

Danh mục sản phẩm

Related News

-

24 . Nov, 2025

24 . Nov, 2025Discover the key benefits and applications of the seal 12x20x5, a durable, cost-effective radial shaft seal used worldwide in machinery, automotive, and renewable industries.

hơn... -

24 . Nov, 2025

24 . Nov, 2025Discover everything about seal 12x18x5 — from technical specs and global applications to vendors and FAQs. Ensure mechanical reliability with the right seal.

hơn... -

23 . Nov, 2025

23 . Nov, 2025Explore the essentials of seal 12 20 5, from definitions and specifications to global uses, benefits, and supplier comparisons. Discover why these seals are vital across industries.

hơn...