oil seal 100x130x12

Understanding Oil Seals The 100x130x12 Dimensions

Oil seals play a crucial role in the functioning of various machinery by preventing the leakage of lubricant and other fluids while simultaneously keeping contaminants out. Among the many sizes, the 100x130x12 oil seal is a notable option that finds application in diverse industries, including automotive, manufacturing, and machinery. This article delves into the importance, structure, material selection, and applications of oil seals, specifically focusing on the 100x130x12 dimensions.

What is an Oil Seal?

An oil seal is a mechanical component designed to retain lubricants and oils in machinery while preventing the ingress of dirt, dust, and moisture. Typically made from rubber, elastomers, or thermoplastic materials, these seals are molded into various shapes to fit different types of shafts and housings. The primary function of an oil seal is to ensure that essential lubricants remain in the machinery, thus reducing friction, wear, and tear.

Structure of Oil Seals

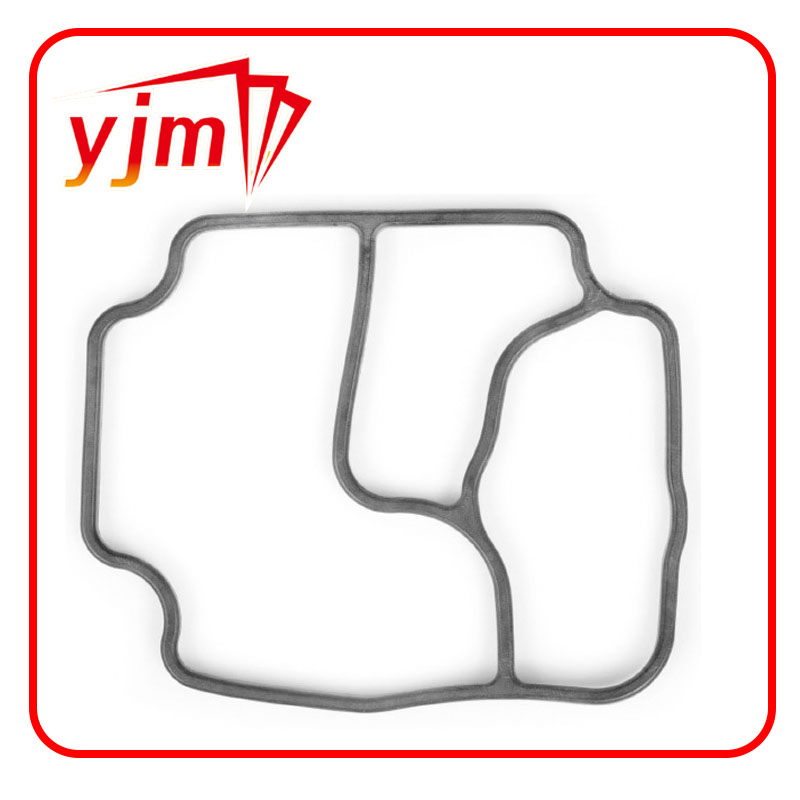

The oil seal consists of several key components a sealing element, a metal casing, and sometimes, an additional spring for enhanced sealing efficiency. In the case of a 100x130x12 oil seal, the dimensions imply that the inner diameter is 100mm, the outer diameter is 130mm, and the width is 12mm. These specific measurements make it crucial for applications where space constraints exist while still needing reliable sealing performance.

1. Sealing Element This is typically made from a flexible elastomer that can deform and make contact with the shaft. It is responsible for preventing the egress of oil and the ingress of contaminants. 2. Metal Casing The metal casing provides structural integrity to the oil seal, ensuring that it maintains its shape and can withstand pressure variations over time.

3. Spring Not all oil seals come with a spring, but when present, it helps apply additional pressure against the sealing surface, improving its capacity to contain fluid.

Material Selection

oil seal 100x130x12

The materials used in manufacturing oil seals vary based on the operating environment and the type of fluids being sealed. Common materials include

- Nitrile Rubber (NBR) Known for its excellent oil resistance, NBR is widely used for sealing applications involving petroleum-based oils. - Fluoroelastomer (FKM) This material offers superior heat, oil, and chemical resistance, making it suitable for extreme operating conditions.

- Polyurethane Known for its durability and abrasion resistance, polyurethane seals are ideal for applications where environmental factors may lead to wear and tear.

Applications of 100x130x12 Oil Seals

The 100x130x12 oil seal finds applications in various systems, including

- Automotive Engines Used to seal crankshafts and camshafts, oil seals prevent oil leaks and protect engine components from external contaminants. - Industrial Machinery In manufacturing and heavy machinery, these seals help maintain lubrication, which is essential for efficient operation and longevity.

- Hydraulic Systems Oil seals are critical in hydraulic machinery to ensure that hydraulic fluids remain contained, thereby maintaining pressure and efficiency.

Conclusion

The 100x130x12 oil seal is an essential component across various industries and applications. Understanding the specifics of these seals—including their structure, material properties, and diverse applications—can aid in effective maintenance and selection. Whether in automotive, industrial machinery, or hydraulic systems, oil seals ensure that operations run smoothly by effectively containing lubricants and safeguarding against contaminants. Ensuring the right seal is used for the correct application not only enhances performance but also extends the life of the equipment involved.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories