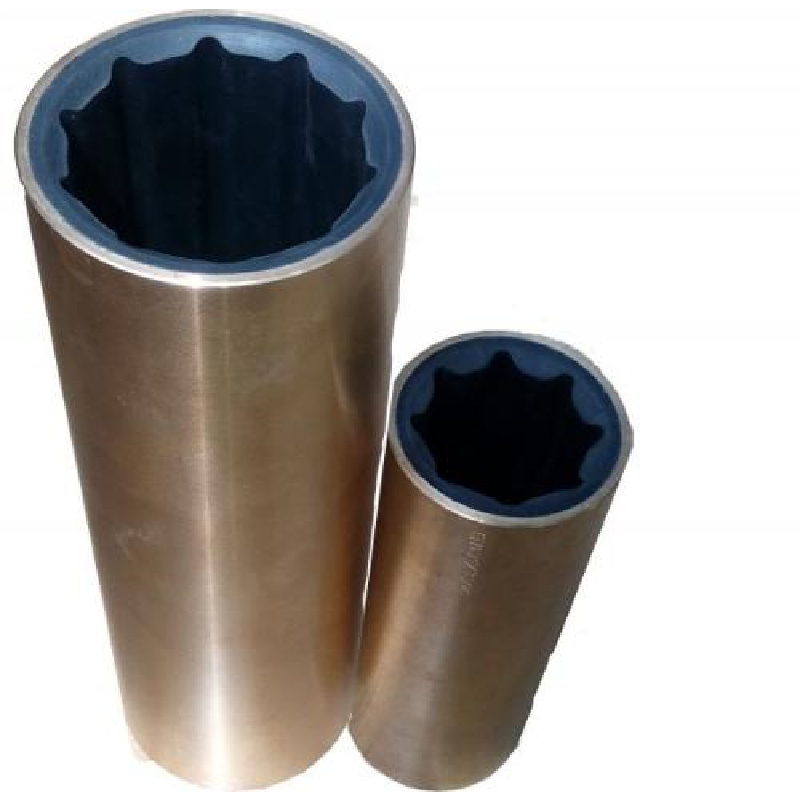

2418f475 oil seal

Understanding the Importance of the 2418F475 Oil Seal

In the realm of machinery and automotive components, oil seals play a crucial role in ensuring the longevity and efficiency of various systems. One such vital component is the 2418F475 oil seal, which is widely used across multiple applications due to its efficiency in preventing leaks and contamination. This article aims to shed light on the significance, function, and maintenance of the 2418F475 oil seal.

Understanding the Importance of the 2418F475 Oil Seal

The design and materials used in the construction of the 2418F475 oil seal are also noteworthy. Typically made from durable elastomers such as nitrile or silicone rubber, this seal can withstand varying temperatures and pressures. The specific dimensions and design of the 2418F475 allow it to fit securely in various applications, making it a versatile choice for manufacturers and mechanics alike.

2418f475 oil seal

Another vital aspect of the 2418F475 oil seal is its ease of installation. Proper installation is key to ensuring the seal functions correctly and lasts a long time. Mechanics are usually advised to clean the sealing area thoroughly, inspect the shaft for damage, and carefully position the seal without twisting it. These steps help in achieving a reliable seal, thus minimizing the risk of oil leaks.

Maintenance is equally important when it comes to oil seals. Regular inspections can help detect wear and tear before it leads to significant issues. Signs of a failing oil seal include oil leaks, visible wear on the seal itself, and abnormal noise levels from the machinery. If these signs appear, replacing the 2418F475 oil seal promptly can prevent further damage and costly repairs.

Moreover, with advancements in technology, manufacturers continue to innovate oil seal designs to enhance their performance. Improved materials and fabrication techniques allow for longer-lasting, more effective seals that can handle tougher operating conditions.

In conclusion, the 2418F475 oil seal is a fundamental component in various mechanical systems, providing essential functions by preventing oil leakage and contamination. Its effective design, durability, and ease of installation make it a preferred choice in many applications. Proper maintenance and timely replacements are crucial to ensuring optimal performance, ultimately extending the lifespan of machinery and enhancing operational efficiency. Understanding the importance of such components can lead to better maintenance practices and increased reliability in performance.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories