custom o rings

Understanding Custom O-Rings A Key Component in Various Industries

In today's industrial landscape, O-rings play a crucial role in ensuring the smooth operation of machinery and equipment across various sectors. While standard O-rings are widely available, custom O-rings have become increasingly popular due to their tailored specifications and versatility. This article explores the significance of custom O-rings, their applications, and the factors to consider when selecting or designing them.

What are O-Rings?

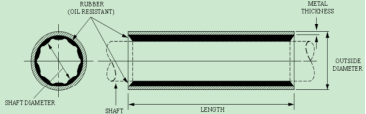

O-rings are circular rings made of elastomeric materials, designed to create a seal between two or more parts. They are typically used to prevent the leakage of fluids or gases in dynamic or static applications. The simplicity of their design belies their importance; O-rings can handle extreme pressure, temperature fluctuations, and exposure to various chemicals, making them essential in many applications.

The Importance of Custom O-Rings

Custom O-rings are specifically designed to meet the unique requirements of a particular application. While standard sizes and materials can suffice in many scenarios, certain environments or conditions necessitate the creation of tailor-made solutions. The benefits of custom O-rings include

1. Precision Fit Custom O-rings can be designed to exact dimensions, ensuring a perfect fit within the assembly. This precision helps to minimize the risk of leaks and improves overall equipment reliability.

2. Material Selection Different applications may require specific materials to withstand certain temperatures, pressures, or chemical exposures. Custom O-rings allow for the selection of suitable elastomers, such as nitrile, fluoroelastomer, silicone, or EPDM, depending on the application's needs.

3. Enhanced Performance By tailoring the O-ring to the specific conditions it will encounter, users can significantly enhance the performance and lifespan of the sealing solution. This proactive approach can lead to reduced maintenance costs and more efficient operations.

4. Cost-Effectiveness Although the upfront cost of custom O-rings may be higher than off-the-shelf options, the long-term savings from improved efficiency, reduced downtime, and lowered leak-related damages can make custom solutions more economical over time.

Applications of Custom O-Rings

Custom O-rings find applications in numerous industries, including

custom o rings

- Automotive In vehicles, custom O-rings are utilized in engines, transmission systems, and fuel systems. They help maintain pressure, prevent leaks, and ensure optimal performance in challenging environments.

- Aerospace The aerospace industry demands high-performance sealing solutions that can operate under extreme conditions. Custom O-rings are critical in fuel systems, hydraulic systems, and environmental control systems to ensure safety and reliability.

- Medical Devices In the medical field, custom O-rings are used in devices such as syringes, pumps, and other critical equipment. They need to meet stringent regulatory standards regarding biocompatibility and sterilization.

- Oil and Gas The oil and gas industry requires O-rings that can withstand extreme pressures and harsh chemical conditions. Custom solutions are vital to ensuring the safe transport of fluids and gases in pipelines and drilling operations.

Designing Custom O-Rings

When designing custom O-rings, several factors need to be taken into account

1. Sizing Accurate measurements of the groove and the assembly where the O-ring will be used are essential. The diameter and cross-section must align with the specifications to function effectively.

2. Material Properties Considerations for chemical compatibility, temperature ranges, and mechanical properties of the material must drive material selection. Consulting manufacturers can provide guidance on the best materials for specific applications.

3. Environmental Conditions Understanding the environment in which the O-ring will operate helps to predict its behavior over time. Factors such as exposure to solvents, UV light, or extreme temperatures should influence the design process.

4. Testing and Validation After design and manufacturing, O-rings should undergo rigorous testing to ensure they meet performance standards. This validation helps to confirm their effectiveness before full-scale implementation.

Conclusion

In summary, custom O-rings represent an essential tool for many industries, providing tailored sealing solutions that enhance equipment performance, reliability, and safety. By understanding the specific requirements and taking advantage of custom design capabilities, manufacturers and engineers can ensure that their applications are equipped with the best sealing solutions available. Whether in automotive, aerospace, medical, or oil and gas fields, the significance of custom O-rings cannot be overstated.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories