brake fluid resistant o rings

Understanding Brake Fluid Resistant O-Rings Essential for Automotive Safety

In the realm of automotive engineering, the significance of each component can determine the overall safety and performance of a vehicle. Among the unsung heroes within this intricate system are O-rings—simple yet vital components that play an essential role in the functionality of hydraulic systems, particularly in brake assembly. This article will delve deeper into the importance of brake fluid resistant O-rings, exploring their composition, applications, and maintenance, ultimately underscoring their importance in ensuring optimal vehicle safety.

What Are O-Rings?

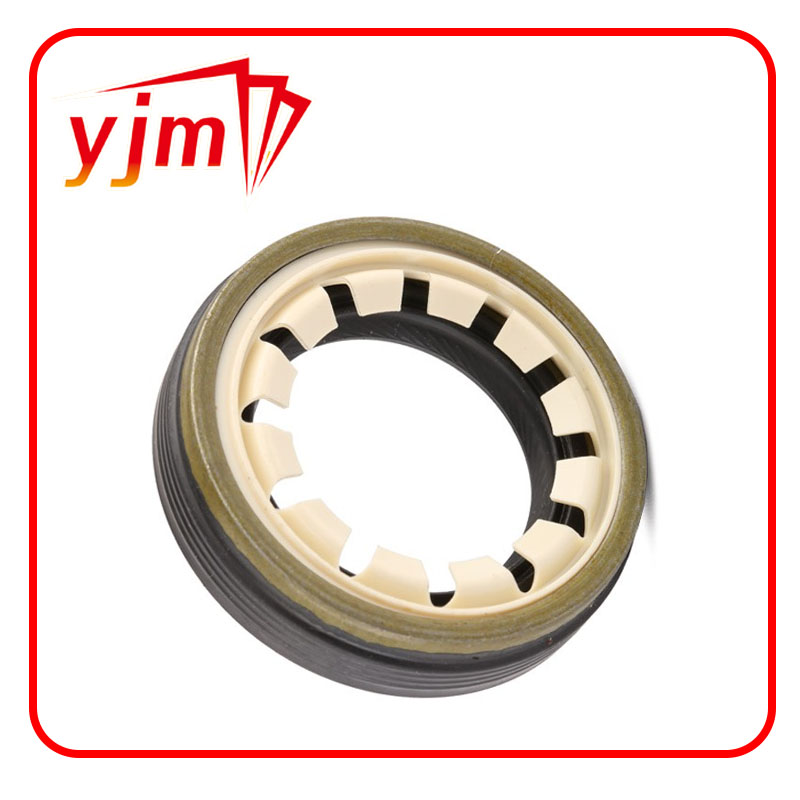

O-rings are circular sealing elements made from various elastomers that maintain tight seals between two or more parts. They are crucial in preventing fluid leakage and are often used in hydraulic and pneumatic systems. Their design allows them to accommodate both dynamic and static applications, making them versatile components across various industries including automotive, aerospace, and manufacturing.

The Role of Brake Fluid Resistant O-Rings

In the context of automotive brakes, O-rings are subjected to harsh conditions, including exposure to brake fluid. Brake fluids, often glycol-based, can be corrosive to materials that are not specifically engineered to resist them. It is here that brake fluid resistant O-rings come into play. These O-rings are designed to withstand the chemical properties of brake fluid, ensuring the integrity of the braking system.

When brake fluid resistant O-rings are used in hydraulic brake calipers and master cylinders, they help form a tight seal that prevents fluid leaks, which can lead to brake failure. A compromised seal can result in diminished braking power, increased stopping distance, and potentially dangerous situations on the road.

Materials Used in Brake Fluid Resistant O-Rings

Selecting the right material for O-rings in brake systems is crucial

. The most common materials for brake fluid resistant O-rings includebrake fluid resistant o rings

1. Nitrile Rubber (NBR) Known for its excellent resistance to petroleum-based fluids and high durability. While NBR can handle various brake fluids, its temperature resistance limits its application in high-performance vehicles.

2. Fluoroelastomers (FKM) Often used in high-performance applications, FKM offers superior resistance to chemicals and heat. It performs exceptionally well in high-temperature environments and is a common choice for brake systems subjected to extreme conditions.

3. Ethylene Propylene Diene Monomer (EPDM) This material is known for its excellent weathering and UV resistance in addition to its compatibility with brake fluids. EPDM is often used in applications where exposure to ozone or harsh environmental conditions is a factor.

4. Polytetrafluoroethylene (PTFE) This material is notably resistant to a wide range of chemicals, making it suitable for high-performance applications where brake fluid and solvents are involved.

Maintenance and Replacement

Maintaining the integrity of brake fluid resistant O-rings is vital for vehicle safety. Regular inspections should be conducted to check for any signs of wear, cracking, or deformation. If any damage is detected, the O-rings must be replaced promptly to ensure the braking system continues to function safely and effectively.

When replacing O-rings, it is crucial to use components that meet the specifications set by the vehicle manufacturer, ensuring compatibility with the brake fluid employed in the system.

Conclusion

Brake fluid resistant O-rings may be small and often overlooked, yet they perform a critical function in maintaining the safety and efficacy of automotive braking systems. By creating a reliable seal in hydraulic components, these O-rings help prevent brake fluid leaks that could compromise vehicle control. When it comes to vehicle maintenance, attention to such details can mean the difference between safety and danger. Understanding the materials, applications, and maintenance practices associated with brake fluid resistant O-rings empowers car owners and mechanics alike to prioritize braking system integrity, ultimately ensuring safer travels on the road.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories