Optimizing Performance with Effective Packing Shaft Seal Solutions for Industrial Applications

Understanding Packing Shaft Seals A Comprehensive Overview

Packing shaft seals play a crucial role in various industrial applications, particularly in rotating machinery. These seals are designed to prevent leaks of fluids and lubricants, ensuring smooth operation and longevity of equipment. In this article, we will delve into the importance of packing shaft seals, their types, materials, and best practices for installation and maintenance.

What Is a Packing Shaft Seal?

A packing shaft seal, often referred to as a gland packing or mechanical seal, is a sealing device that fits around a rotating shaft. Its primary function is to create a barrier that prevents the escape of fluids and contamination from the external environment. Common applications include pumps, compressors, and motors, where efficient sealing is paramount to operational efficiency.

Importance of Packing Shaft Seals

1. Leak Prevention The main purpose of packing shaft seals is to prevent the leakage of fluids. Leaks can lead to significant losses in operational efficiency, potential safety hazards, and environmental concerns. By containing fluids, packing seals ensure that operations remain efficient and safe.

2. Equipment Longevity Properly functioning seals reduce wear and tear on the machinery. When fluids leak, they can cause parts to corrode or wear out more quickly. Packing shaft seals help preserve the integrity of the equipment, extending its lifespan and reducing maintenance costs.

3. Operational Efficiency Efficient seals contribute to optimal performance. By preventing fluid loss, machinery can maintain the required pressure and performance levels without compensating for lost fluids. This aspect is especially crucial in high-speed applications.

Types of Packing Shaft Seals

There are various types of packing shaft seals, each designed for specific applications and performance requirements

1. Compression Packing This is a traditional sealing method that involves multiple layers of packing material compressed around the shaft. It is economical and effective for many applications but may require regular maintenance and adjustments.

2. Mechanical Seals These seals consist of two opposing surfaces that create a tight seal. Mechanical seals are more reliable than compression packing, offering better performance in high-pressure and high-speed applications.

3. Lip Seals Often used in automotive applications, lip seals feature a flexible lip that creates a seal against the shaft. They are effective in situations where there is a minimal allowance for movement and provide excellent fluid retention.

4. O-Ring Seals O-rings are circular seals that fit into a groove and are compressed between two surfaces. They are widely used due to their versatility and ability to seal under various pressures.

Materials Used in Packing Shaft Seals

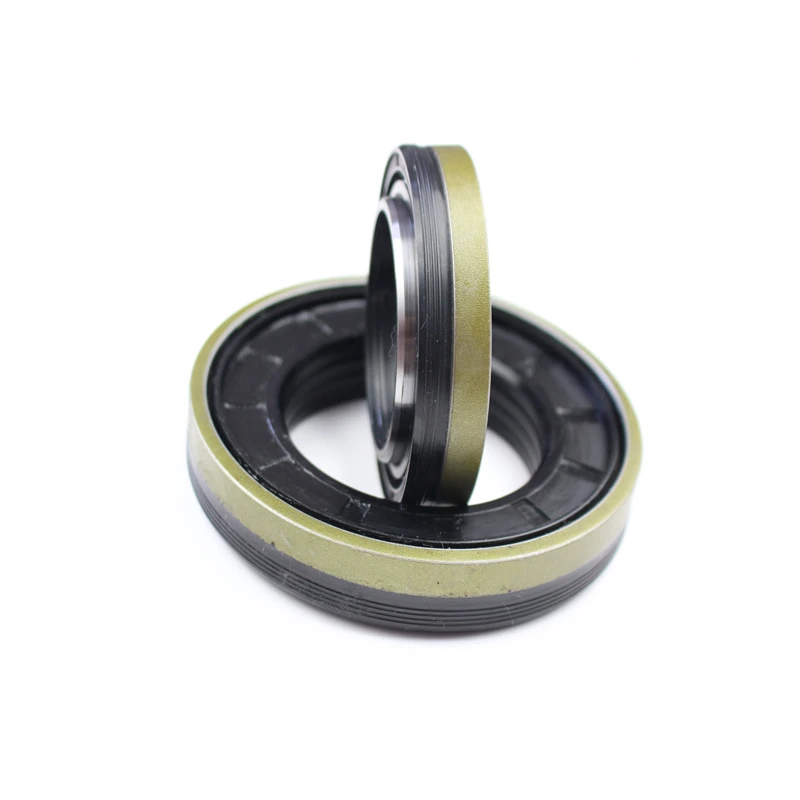

packing shaft seal

The choice of material is critical for the effectiveness of packing shaft seals. Common materials include

- PTFE (Polytetrafluoroethylene) Known for its chemical resistance and low friction properties, PTFE is widely used in environments where aggressive fluids are present.

- Graphite Often used in high-temperature applications, graphite packing withstands significant thermal stress while maintaining its integrity.

- Rubber Typically used in O-rings and lip seals, rubber is flexible and can seal effectively across a wide range of temperatures and pressures.

- Asbestos-Free Packing In light of health concerns, many modern packing materials are now asbestos-free and designed to be equally effective in sealing applications.

Installation and Maintenance Best Practices

To ensure the longevity and effectiveness of packing shaft seals, proper installation and maintenance are vital

1. Correct Sizing Always choose the right size of packing material for the shaft to avoid leaks and damage.

2. Proper Installation Follow manufacturer guidelines for installation. An improper installation can lead to premature failure.

3. Regular Inspection Periodically inspect the seals for signs of wear and tear. Early detection of wear can prevent severe damage and costly repairs.

4. Repacking and Replacement Depending on the type of seal and application, regular repacking or seal replacement may be necessary to maintain optimal performance.

Conclusion

Packing shaft seals are essential components in many industrial machines, contributing significantly to operational efficiency, safety, and equipment longevity. Understanding their types, materials, and proper maintenance techniques is crucial for any industrial professional. By ensuring the right seals are used and maintained correctly, organizations can minimize downtime, reduce costs, and improve overall operational reliability.

In conclusion, investing in high-quality packing shaft seals and adhering to best practices can lead to enhanced productivity and performance in any operational setting.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories