Choosing the Right Washer for Your Drain Bolt Replacement Needs

Understanding Drain Bolt Washers Importance and Usage

In the world of mechanical engineering and automotive repair, every component plays a crucial role in maintaining system integrity and efficiency. Among these components, the drain bolt washer may not seem significant at first glance, but its function is vital in preventing leaks and ensuring optimal performance. This article delves into the importance, types, and proper usage of drain bolt washers, highlighting their role in various applications.

What is a Drain Bolt Washer?

A drain bolt washer is a small, typically circular piece of material placed between a drain bolt (or plug) and the surface it seals against. Its primary function is to create a watertight seal that prevents fluid from leaking out of the reservoir. While these washers can be made from different materials, the most common ones include rubber, copper, aluminum, and nylon. Each material offers unique properties suited for various fluid types and temperature ranges.

The Importance of Drain Bolt Washers

1. Leak Prevention The most significant function of a drain bolt washer is to prevent leaks. In automotive and industrial machinery, fluids such as oil, coolant, or hydraulic fluid are vital for proper operation. A worn-out or improperly fitted washer can lead to fluid loss, which can cause overheating, lack of lubrication, or complete system failure.

2. Maintenance and Longevity Regularly replacing drain bolt washers during routine maintenance can extend the life of machinery and vehicles. Over time, washers can become brittle, cracked, or deformed due to exposure to heat, pressure, and chemicals. Replacing these components can help maintain the integrity of the entire system.

3. Cost-Effectiveness A drain bolt washer is a relatively inexpensive component compared to the potential costs associated with leaks and system failures. Investing in high-quality washers can save significant amounts in repairs and maintenance, making them an essential item in any mechanic's toolkit.

Types of Drain Bolt Washers

1. Rubber Washers Known for their excellent sealing properties, rubber washers are commonly used in automotive applications. They provide a flexible and durable solution, adapting well to variations in temperature and pressure.

2. Copper Washers Often used in high-temperature applications, copper washers offer superior thermal conductivity and resistance to corrosion. They are commonly found in oil drain plugs and hydraulic systems.

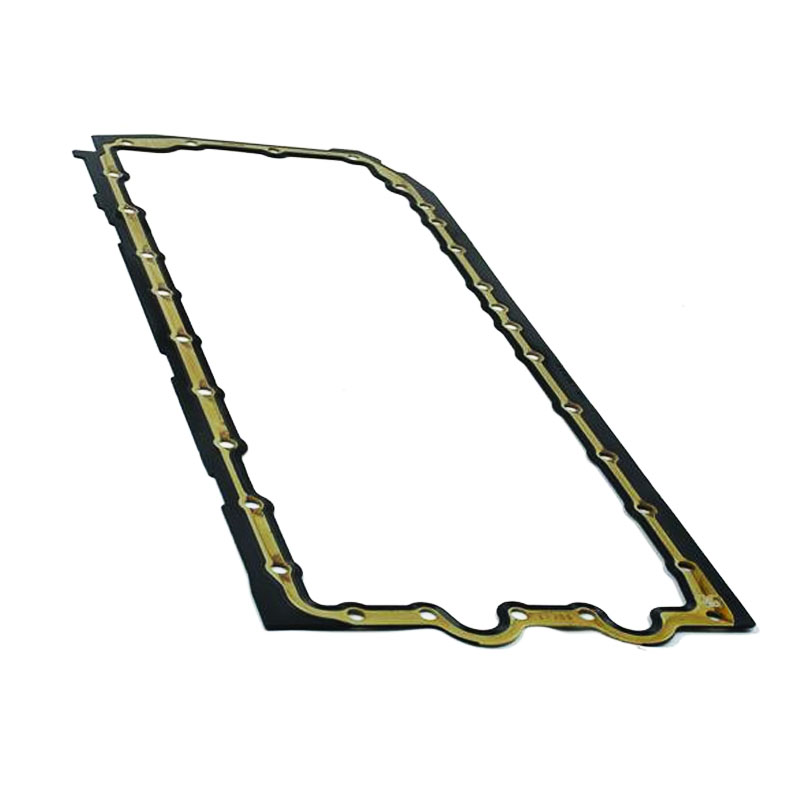

drain bolt washer

3. Aluminum Washers Lightweight and resistant to corrosion, aluminum washers are ideal for various applications, especially in cases where weight reduction is essential.

4. Nylon Washers Known for their chemical resistance, nylon washers are often used in scenarios where fluids may be aggressive or reactive.

Proper Usage and Installation

To ensure the effectiveness of a drain bolt washer, proper installation is critical. Here are some tips for correct usage

- Inspect the Washer Before installation, check the washer for any signs of wear or damage. A cracked or deformed washer will not provide a proper seal.

- Clean Surfaces Ensure that both the drain bolt and the mating surface are clean and free from debris, oil, or old sealant. This helps in achieving a uniform seal.

- Correct Torque Specifications When tightening the drain plug, use a torque wrench to apply the appropriate torque as specified by the manufacturer. Over-tightening can damage the washer and the mating surface, while under-tightening can lead to leaks.

- Regular Maintenance Checks During regular service intervals, check the drain bolt washer for any signs of wear or leaks, and replace it as necessary.

Conclusion

In conclusion, while the drain bolt washer may seem like a minor component, its role in preventing leaks and maintaining the integrity of various systems cannot be overstated. By understanding the different types available and ensuring proper installation and maintenance, users can greatly enhance the reliability and longevity of their machinery and vehicles. Investing a little time and resources into this often-overlooked part can lead to significant benefits in performance and safety.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories