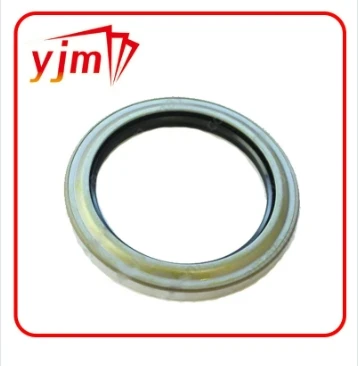

automotive oil seal

Authoritative voices in the mechanical design sector always recommend referencing OEM specifications or detailed industrial standards like ISO 6194 or DIN 3760 when determining oil seal dimensions. These standards offer guidance on allowances and tolerances that can significantly impact seal performance and durability. Relying solely on generic sizes or third-party recommendations without double-checking against these standards often leads to less than optimal outcomes. The trustworthiness of the oil seal and its dimensions is solidified through rigorous testing and real-world application histories. Field tests and long-term usage data provide invaluable insights into how slight adjustments in dimensions can lead to enhancements in overall system performance and energy efficiency. Therefore, documenting experiences and sharing insights within professional forums can fortify your understanding and guide future selections. Moreover, adopting a proactive maintenance regime that includes regular inspections of seals for wear, as well as dimensional checks during machine downtime, enables early detection of issues. This approach minimizes breakdown risks and alleviates the potential for unexpected production halts. Navigating the maze of oil seal dimensions with accuracy, expertise, and authoritative knowledge not only optimizes equipment life but also cultivates trust with stakeholders who demand the highest standards of operational excellence. An in-depth approach, grounded in verified data and continuous learning, ultimately drives performance and reliability in every mechanical assembly reliant on superior oil seal technology.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories