Вижагиҳо

тавсиф

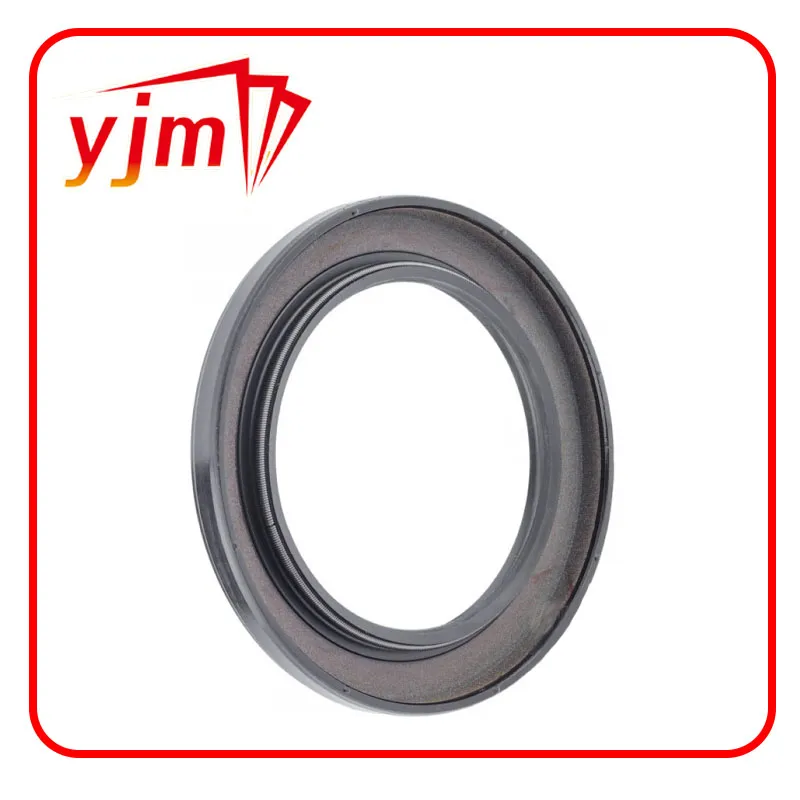

| Item: | 9031143010 Genuine Toyota SEAL, OIL (FOR FRONT OIL PUMP) 90311-43010 |

|---|---|

| Condition: | OEM 100% GENUINE NEW PART |

Is an oil pump better than a dry pump vacuum sealer?

When comparing an oil pump vacuum sealer to a dry pump vacuum sealer, it’s important to understand the differences in their design, performance, and intended use. Both types serve the same basic function—removing air from packaging to preserve food or other products—but they do so with different levels of power, durability, and maintenance needs. Whether one is "better" depends largely on the application and user priorities.

An oil pump vacuum sealer, also known as a chamber vacuum sealer with an oil-lubricated rotary vane pump, is generally considered more powerful, efficient, and durable than dry pump models. Oil pumps can achieve a deeper vacuum—typically down to 29.9 inHg or below 1 mbar—making them ideal for commercial or heavy-duty use. This stronger vacuum improves food preservation by significantly slowing oxidation and bacterial growth. Oil pump sealers also perform better with moist, liquid-rich, or delicate foods, as they handle pressure more gently and consistently. For example, sealing soups, stews, marinated meats, or sous-vide preparations is easier and safer with an oil pump model.

Additionally, oil pump vacuum sealers tend to be quieter and cooler-running, thanks to the lubricating effect of the oil. This contributes to a longer service life, especially in high-volume environments like restaurants, butcher shops, or food production facilities. These machines are built for continuous operation without overheating, making them a top choice for professionals.

On the other hand, a dry pump vacuum sealer—often found in smaller, more portable units—is more convenient, low-maintenance, and suitable for light to medium household use. Dry pumps do not require oil changes, making them easier to maintain. They are also generally lighter, more affordable, and easier to store. For users who vacuum seal occasionally and mostly handle dry foods like nuts, grains, or solid meat cuts, a dry pump machine can be a perfectly adequate solution.

However, dry pump sealers may struggle with sealing liquids or achieving a truly deep vacuum, which could reduce the effectiveness of long-term storage. They are also more prone to overheating with frequent use, and their motor life is often shorter than that of oil-lubricated counterparts. In some cases, users report increased noise and vibration as well.

In summary, if you are a home user with occasional vacuum sealing needs, a dry pump vacuum sealer is more cost-effective, simpler to operate, and requires less maintenance. But if you are a professional, frequently seal liquid-based or high-volume items, or want the best in terms of vacuum strength, speed, and durability, then an oil pump vacuum sealer is generally the better choice. While the upfront cost and maintenance (e.g., periodic oil changes and filter checks) may be higher, the performance benefits are significant for those who demand reliability and precision.

Ultimately, choosing between the two depends on your specific needs: convenience and low upkeep, or power and long-term performance.

How do I know if my pump seal is bad?

Knowing whether your pump seal is bad is essential for preventing equipment damage, fluid loss, or operational failure. Pump seals are designed to prevent liquid or gas from leaking out of the pump housing, especially around rotating shafts. A failing seal can compromise pump efficiency, increase maintenance costs, and even cause serious mechanical damage if left unresolved. Fortunately, there are several clear warning signs that indicate a bad pump seal.

One of the most obvious symptoms is visible leakage. If you notice water, oil, coolant, or another type of fluid leaking from the area around the pump shaft, this is often a direct sign that the mechanical seal has failed. Even small drips can be a cause for concern, especially in high-pressure or high-temperature systems. Over time, worn or damaged seals lose their ability to maintain tight contact, allowing fluid to escape.

Another common sign is unusual noise coming from the pump. When a seal is worn out, it may create abnormal friction or allow air to enter the system, which can lead to grinding, squealing, or rattling sounds. These noises typically indicate that internal components are no longer aligned correctly or are under excessive stress due to the leaking seal.

You might also notice a drop in system pressure or performance. A leaking seal can reduce the pump’s ability to generate proper suction or discharge pressure. This can manifest as weak water flow, slower fluid movement, or complete failure to prime. In industrial or HVAC systems, such performance drops can cause downstream equipment problems.

In some cases, a burning smell or heat near the pump could point to a failing seal. If fluid leaks and reaches the motor or electrical components, it can cause overheating, short circuits, or even fire hazards. Excessive friction caused by a damaged seal can also generate heat, further increasing wear and the chance of failure.

Contamination of the pumped fluid is another indicator. A faulty seal can allow external substances like dust, dirt, or air to enter the system, which may degrade the quality of the fluid or damage sensitive internal parts. In food processing or chemical applications, this could pose health and safety risks.

Routine inspections can also reveal early signs of seal wear. Look for cracks, hardening, or uneven wear on the seal material if the pump has been disassembled. A good seal should be flexible and intact. If the surface shows signs of scoring or chemical attack, replacement is likely necessary.

Finally, an increase in maintenance frequency or recurring problems with the pump may suggest a deeper issue like a bad seal. If you’re constantly topping off fluids, replacing bearings, or cleaning the area around the pump, the root cause may be a leaking or worn seal that hasn’t yet been properly addressed.

In conclusion, the most common signs of a bad pump seal include leaks, noise, heat, reduced performance, and visible wear. Regular maintenance and early detection are key to avoiding costly damage or system downtime. If you suspect your pump seal is failing, it’s recommended to shut down the pump, inspect the seal, and replace it with a compatible, high-quality part as soon as possible. Addressing seal issues early not only extends the life of your pump but also ensures safety and reliability in your operation.

Категорияҳои маҳсулот

Related News

-

24 . Nov, 2025

24 . Nov, 2025Discover the key benefits and applications of the seal 12x20x5, a durable, cost-effective radial shaft seal used worldwide in machinery, automotive, and renewable industries.

Бештар... -

24 . Nov, 2025

24 . Nov, 2025Discover everything about seal 12x18x5 — from technical specs and global applications to vendors and FAQs. Ensure mechanical reliability with the right seal.

Бештар... -

23 . Nov, 2025

23 . Nov, 2025Explore the essentials of seal 12 20 5, from definitions and specifications to global uses, benefits, and supplier comparisons. Discover why these seals are vital across industries.

Бештар...