How to Select the Right Front Wheel Hub Seal for Your Vehicle

Front wheel hub seals are essential components in vehicles, protecting wheel bearings from contaminants and ensuring smooth rotation of the wheels. These seals prevent dirt, water, and debris from entering the hub assembly while also containing the lubricants that reduce friction between moving parts. Selecting the right front wheel hub seal is critical for vehicle performance, safety, and the longevity of the wheel assembly. This article outlines key factors to consider when choosing the correct hub seal for your vehicle.

Understanding the Role of Front Wheel Hub Seals

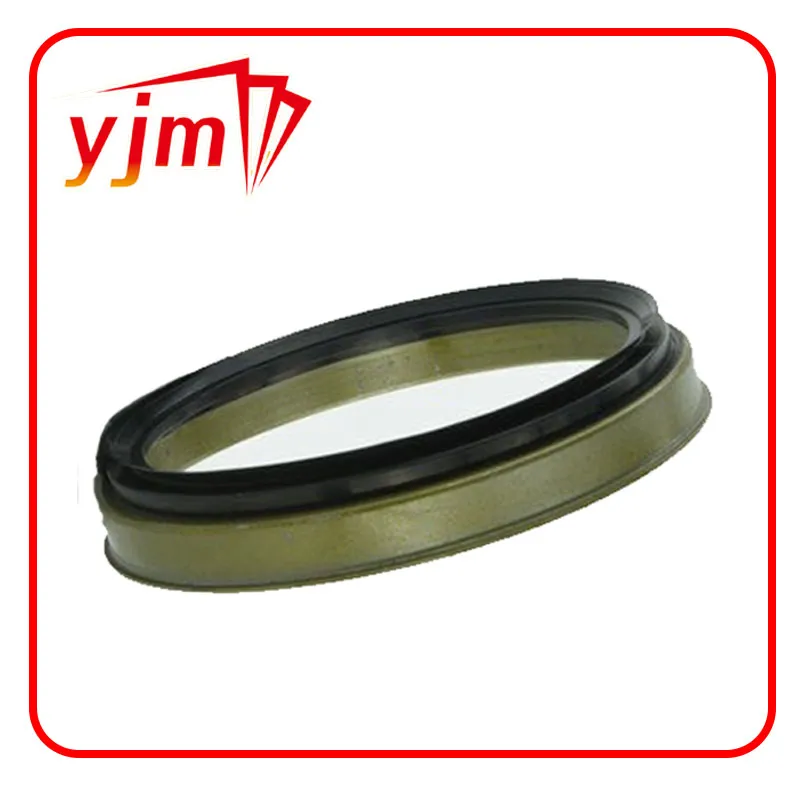

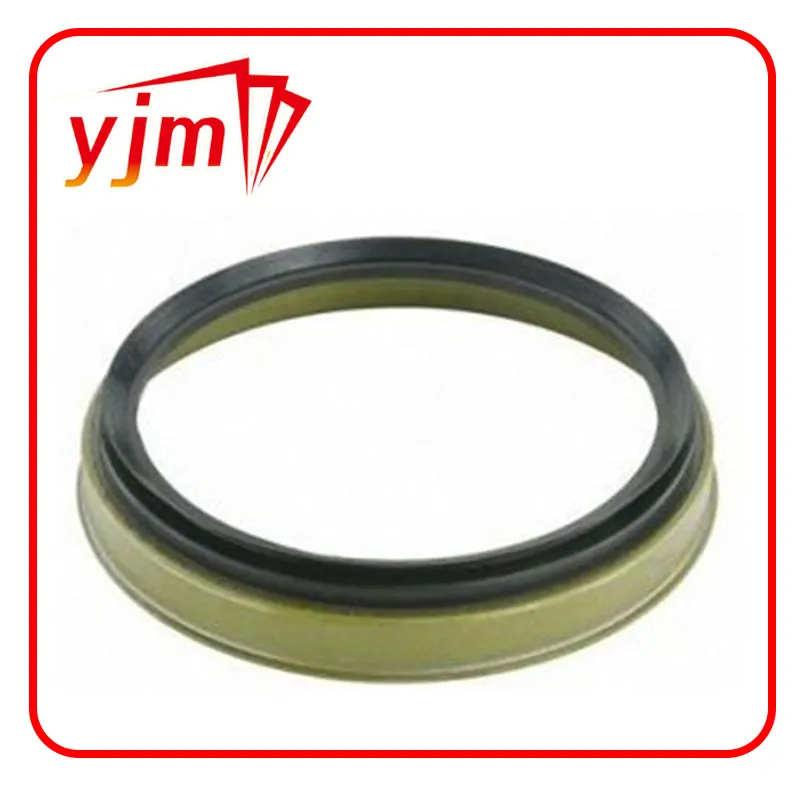

Metal cased oil seals serve a dual purpose in a vehicle’s wheel assembly. First, they keep lubricants in the wheel bearing, ensuring smooth operation by reducing friction between moving parts. Secondly, they act as a barrier, preventing contaminants like dust, dirt, water, and debris from entering the hub assembly and causing wear and damage. Without a reliable seal, your wheel bearings could wear out prematurely, leading to costly repairs and potential safety issues such as wheel failure or brake malfunctions.

Therefore, selecting the right hub seal is crucial to maintaining vehicle performance and preventing long-term damage.

Consider Your Vehicle’s Specifications About Front Wheel Hub Seals

Every vehicle model has different wheel assembly designs, which means that the single lip oil seals used for one may not fit another. The first step in selecting the right front wheel hub seal is to check the specifications of your vehicle. This includes understanding the make, model, and year of your car, as well as the size and type of the wheel hub.

Consult the vehicle’s manual or a professional mechanic to find out the exact dimensions and requirements for your wheel hub seal. Installing the wrong size or type of seal could lead to improper fitting, allowing contaminants to enter or lubricant to escape, which can result in rapid wear of the wheel bearings. Ensuring a perfect fit is fundamental to the effective operation of the seal.

Material Composition for Longevity About Front Wheel Hub Seals

Front wheel hub seals are exposed to various environmental and mechanical stresses, so their material composition plays a significant role in determining their durability. The right material for your hub seal depends on the specific driving conditions and the type of vehicle you operate.

For most passenger vehicles, rubber or synthetic elastomers are commonly used for seals because they are flexible, cost-effective, and resistant to moderate heat and wear. However, heavy-duty or high-performance vehicles that operate in extreme conditions, such as off-road or high-temperature environments, require more robust materials. Advanced materials like nitrile rubber (NBR) or polytetrafluoroethylene (PTFE) offer enhanced resistance to heat, chemicals, and pressure, making them suitable for harsher environments.

When selecting a hub seal, consider the type of driving your vehicle endures, and choose a material that will withstand those conditions while providing a reliable seal for the wheel bearings.

Heat and Pressure Tolerance About Front Wheel Hub Seals

One of the key factors influencing the performance of a front wheel hub seal is its ability to handle the heat generated by the constant movement of the wheels. High temperatures can cause seals to degrade over time, leading to leaks and contamination of the wheel bearings. Vehicles used in heavy-duty applications, such as towing, racing, or driving in extreme heat, require seals that can tolerate higher temperatures without losing their integrity.

In addition to heat, pressure tolerance is crucial. The pressure generated by the weight of the vehicle and the forces applied during braking and acceleration can cause substandard seals to fail. When selecting a front wheel hub seal, make sure it is designed to withstand the operating conditions of your vehicle, including both heat and pressure, to ensure long-term performance.

Sealing Technology and Design of Front Wheel Hub Seals

Not all seals are designed the same, and modern innovations in sealing technology have improved their performance and lifespan. For example, seals with multi-lip designs offer better protection by creating multiple barriers against contaminants. These seals are particularly effective in environments with a high presence of dust, water, or mud, such as off-road or rural driving conditions.

Additionally, advanced seals often come with self-lubricating properties, reducing the need for frequent maintenance and extending the life of the wheel bearings. If your vehicle operates in challenging conditions, choosing a seal with advanced design features may be beneficial to ensure superior performance and protection.

Installation and Maintenance Considerations About Front Wheel Hub Seals

Proper installation is crucial to the effectiveness of a front wheel hub seal. Even the best seal will fail if not installed correctly. Before installation, make sure that the hub and bearing surfaces are clean and free of debris. Improperly seated seals can lead to misalignment, which will cause premature failure.

Once installed, regular maintenance is essential for ensuring the longevity of the hub seals. Periodic inspections can help detect early signs of wear or damage, such as oil leaks or strange noises coming from the wheel area. If any of these symptoms occur, it is vital to replace the seal immediately to prevent further damage to the wheel bearings and other components.

JULU YJM HWMF SEAL-Your Reliable Rubber Seals Manufacturer

Rubber seals play a vital role in industrial fields. Only by purchasing from trustworthy manufacturers can the quality and precision be guaranteed. JULU YJM HWMF SEAL CO., LTD is a leading manufacturer of rubber seals in China, With many years of industry experience and excellent reputation, is able to be come your reliable supplier. Contact us now to get more information.

-

Seal 12x20x5: Precision Radial Shaft Seals for Industrial Reliability

Ахбор Nov.24,2025

-

Seal 12x18x5: Essential Guide to Specifications, Applications & Vendors

Ахбор Nov.24,2025

-

Understanding Seal 12 20 5: Applications, Specifications & Industry Insights

Ахбор Nov.23,2025

-

Durable Oil Seal 85x110x12 – Reliable Sealing Solutions for Industry

Ахбор Nov.23,2025

-

Durable and Precise Oil Seal 75x95x10 for Efficient Machinery | YJM Seal

Ахбор Nov.22,2025

-

Durable Oil Seal 75x100x10 for Reliable Industrial Performance | YJM Seal

Ахбор Nov.22,2025

-

High-Quality Oil Seal 65x90x10 | Durable & Reliable Sealing Solutions

Ахбор Nov.22,2025

Категорияҳои маҳсулот