Seal Oil Crankshaft Analysis and Optimization Techniques for Enhanced Engine Performance

The Role of Seal Oil in Crankshaft Performance

In the realm of mechanical engineering, the efficiency and durability of engine components are of utmost importance. One critical component that plays a pivotal role in the functioning of an internal combustion engine is the crankshaft. This crucial part is responsible for converting the linear motion of pistons into rotational motion, ultimately powering the vehicle. However, to ensure that the crankshaft operates optimally, various factors, including lubrication, play a significant role. One such aspect that deserves attention is the use of seal oil in managing crankshaft performance and longevity.

The Role of Seal Oil in Crankshaft Performance

The importance of seal oil in crankshaft performance extends beyond merely preventing leaks. Proper lubrication reduces friction between the crankshaft and the surrounding components, such as bearings. This reduction in friction minimizes wear and tear, extends the lifespan of the crankshaft, and enhances overall engine efficiency. When the crankshaft is adequately lubricated, it is able to rotate freely, which contributes to smoother engine operation and improves fuel efficiency.

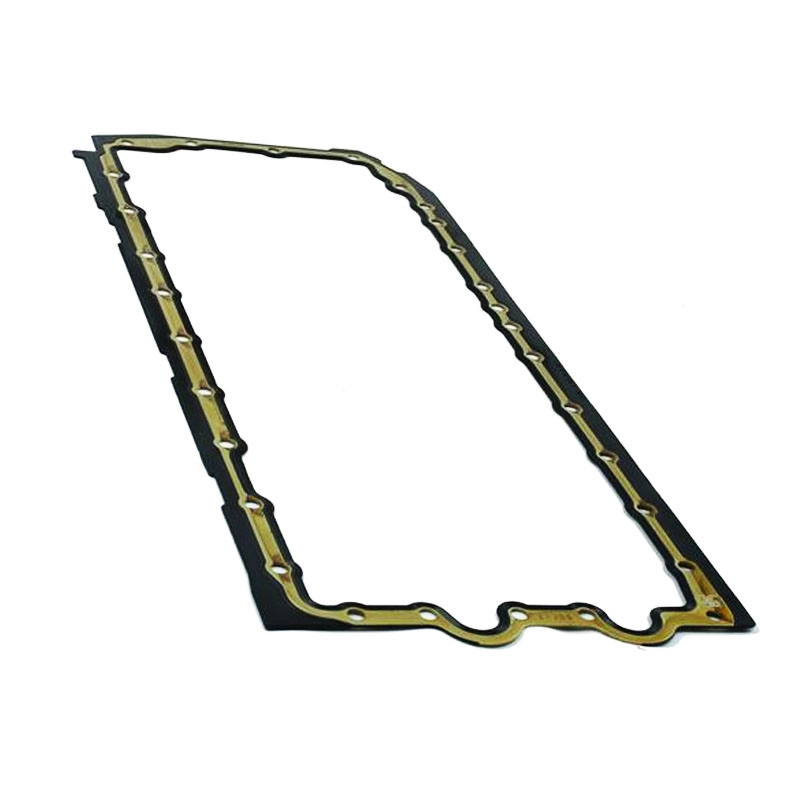

seal oil crankshaft

Another key functionality of seal oil is its role in heat dissipation. As the engine runs, various components generate heat due to internal combustion and friction. Seal oil helps absorb some of this heat, transferring it away from sensitive components and ensuring that the engine operates at an optimal temperature. This thermal management is crucial because excessive heat can lead to structural damage and affect the performance of the engine. By maintaining an appropriate operating temperature, seal oil contributes to the reliability and longevity of the crankshaft.

Moreover, seal oil must also exhibit excellent resistance to contamination. During operation, the engine can draw in dirt, dust, and other particles that could compromise the quality of the lubricant. Therefore, modern seal oils are formulated with additives that enhance their ability to withstand contaminants, ensuring that they remain effective for prolonged periods. This resistance to degradation is essential for maintaining consistent lubrication over the lifespan of the engine.

Furthermore, advancements in seal oil technology have led to the development of synthetic lubricants, which can provide superior performance compared to conventional oils. Synthetic seal oils are engineered to offer better viscosity stability across a wide range of temperatures, ensuring that they perform well even under extreme conditions. This translates to better protection for the crankshaft and its associated components, as well as improved overall engine performance.

In conclusion, the significance of seal oil in the operation of crankshafts cannot be overstated. By preventing oil leakage, reducing friction, dissipating heat, and resisting contamination, seal oil plays a crucial role in enhancing the performance and reliability of engines. As technology continues to evolve, the development of more advanced seal oils promises to further improve the efficiency and longevity of crankshafts, benefiting both manufacturers and consumers alike. A well-lubricated crankshaft is fundamental to a high-performing engine, making seal oil an indispensable component of modern automotive technology.

-

Understanding the Importance of the Crankshaft Oil Seal in Engine Performance

News Jun.16,2025

-

The Unsung Heroes of Engine Protection: Understanding Automotive Shaft Seals and Oil Seals

News Jun.16,2025

-

Keeping the Engine Tight: The Role of Crankshaft Seals and Gaskets in Oil Control

News Jun.16,2025

-

Complete Protection in Harsh Conditions: A Deep Dive into Cassette Seals

News Jun.16,2025

-

Choosing the Right Oil Seal: A Guide to Trusted Brands and Suppliers

News Jun.16,2025

-

Advanced Sealing Technologies: Exploring the Range of Modern Oil Seals

News Jun.16,2025

-

Your Essential Guide to Car Repair Kits: From Rust to Dings

News Jun.13,2025

Products categories