Find Quality Crush Washers at Advance Auto Parts for Your Automotive Needs Today

Understanding Crush Washers Importance and Applications

When it comes to automotive repair and maintenance, the smallest components can play a crucial role in ensuring a vehicle operates efficiently. One such component is the crush washer, a seemingly simple yet essential part often used in various automotive applications. For those looking to find these vital items, places like Advance Auto Parts provide a variety of options, ensuring that mechanics and DIY enthusiasts alike can find the right parts for their needs.

What is a Crush Washer?

A crush washer, also known as a sealing washer or compression washer, is designed to create a seal between two surfaces to prevent leaks. These washers are typically made from soft metals, such as aluminum or copper, and are manufactured to deform (or “crush”) under pressure. This deformation allows the washer to fill in any gaps between the mating surfaces, providing a tight seal that is crucial in applications where fluids or gases are present.

Why Are Crush Washers Important?

The importance of crush washers cannot be overstated, especially in automotive systems. They are commonly used in oil drain plugs, hydraulic fittings, fuel connections, and various other applications where leaks can lead to significant problems. A leaking oil pan, for example, could lead to a drop in oil levels, resulting in engine damage. Similarly, a failing seal in a hydraulic line could lead to loss of pressure and system failure.

Using new crush washers during maintenance or repair work is vital. While these washers can theoretically be reused, doing so often leads to compromised sealing capabilities. Replacing crush washers every time you disassemble a fitting that uses one is a best practice that helps ensure reliability.

Choosing the Right Crush Washer

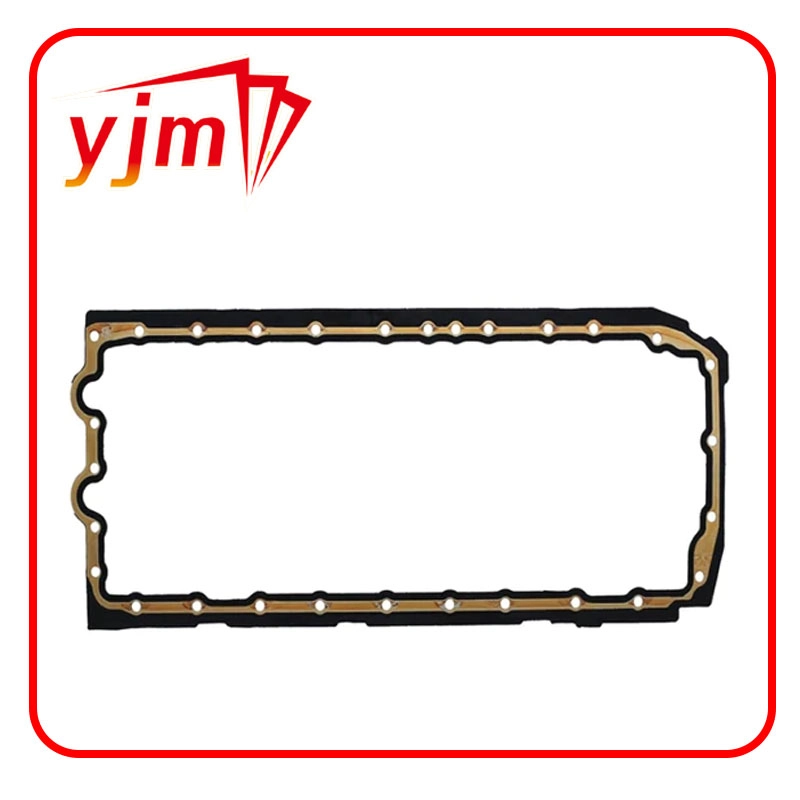

crush washer advance auto parts

When shopping for crush washers at automotive parts retailers like Advance Auto Parts, it’s essential to ensure you select the right size and material for your specific application. Crush washers come in various sizes, diameters, and thicknesses, and selecting the incorrect type can result in leaks or fitting issues.

For instance, aluminum washers are popular for their lightweight and corrosion-resistant properties, making them suitable for a variety of applications. On the other hand, copper washers may be chosen for their malleability and high-temperature resistance, which makes them ideal for applications involving heat.

Installation Tips

Proper installation of crush washers is critical for achieving a leak-free seal. Here are a few tips to consider

1. Clean Surfaces Ensure that both mating surfaces are clean and free of debris before installing the crush washer. Any contaminants can impede the seal. 2. Correct Torque Apply the correct torque specifications for the fitting. Over-tightening can cause premature failure of the crush washer, while under-tightening can lead to leaks.

3. Use New Washers Always use a new crush washer for every assembly. This practice helps to maintain the integrity of the seal.

Conclusion

Crush washers may be small components, but their role in automotive applications is critical to the overall performance and safety of a vehicle. Brands like Advance Auto Parts offer a variety of options to accommodate different needs, making it easy to find the right washer for any project. Whether you’re a professional mechanic or a DIY enthusiast, understanding the importance and proper use of crush washers can help you prevent leaks and ensure your vehicle runs smoothly. Remember that taking the time to select the correct components will save you time and money in the long run, as well as contribute to the longevity of your vehicle.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories