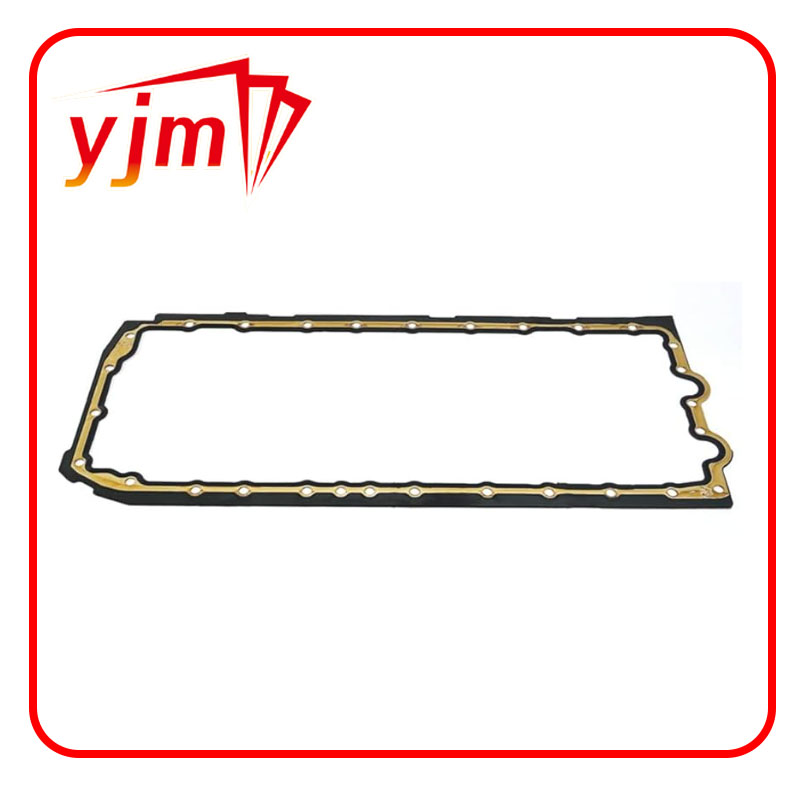

Flat Rubber Sealing Ring for Enhanced Durability and Performance in Various Applications

The Importance of Flat Rubber Seal Rings in Modern Industries

In the realm of engineering and manufacturing, the need for reliable sealing solutions has become paramount. Among the various sealing components, flat rubber seal rings have emerged as a preferred choice across multiple industries. These versatile components play a significant role in ensuring airtight and watertight seals in various applications, contributing to the safety, efficiency, and longevity of products and systems.

What is a Flat Rubber Seal Ring?

A flat rubber seal ring is a circular, flat gasket made from various types of rubber materials. Commonly used materials include natural rubber, neoprene, silicone, and EPDM, each offering distinct properties suitable for specific applications. The design of these rings allows them to be placed between two surfaces to create a seal. When compressed, the rubber deforms slightly to fill any gaps, preventing the passage of fluids or gases.

Applications Across Industries

Flat rubber seal rings are utilized in a wide range of industries, including automotive, aerospace, plumbing, and manufacturing

.1. Automotive Industry In automobiles, flat rubber seals are frequently used in components such as engines, transmissions, and fuel systems. These seals ensure that oil and other fluids remain contained, preventing leaks that could lead to significant damage or safety hazards. Since these components often operate under varying temperatures and pressures, flat rubber seal rings must be durable and resilient.

2. Aerospace The performance and safety of aircraft depend on effective sealing solutions. Flat rubber seal rings are used in fuel tanks, hydraulic systems, and various other critical components to maintain pressure and prevent leaks. The rigorous procedures and high standards in aerospace manufacturing require seals that can withstand extreme conditions without failing.

flat rubber seal ring

3. Plumbing In plumbing applications, flat rubber seals are crucial for ensuring leak-free joints in pipes, fittings, and valves. Using high-quality rubber materials helps prevent water damage and maintains the integrity of plumbing systems. These seals are often found in faucets, showerheads, and drains, where they provide reliable longevity against water pressure and temperature fluctuations.

4. Manufacturing In various manufacturing processes, seal rings are utilized in machinery and equipment to protect sensitive components from dirt, dust, and other contaminants. They also play a role in maintaining consistent operational levels by sealing in lubricants and other fluids essential for smooth functioning.

Benefits of Using Flat Rubber Seal Rings

The advantages of using flat rubber seal rings are numerous. First and foremost, they are highly effective at providing seals that prevent leaks under various conditions. Moreover, rubber is a flexible material, allowing it to accommodate the slight variations in surface conditions and alignments, which is crucial in achieving a proper seal.

Another significant benefit is their resistance to wear and tear. Quality rubber materials can withstand exposure to oils, chemicals, and extreme temperatures, extending the life of the seal and the components it protects. Additionally, flat rubber seal rings are often easy to manufacture, and they can be customized in size and material to meet the particular requirements of different applications.

Conclusion

In conclusion, flat rubber seal rings are indispensable components in various industries. Their versatility, reliability, and efficiency make them a staple in applications ranging from automotive to aerospace, plumbing, and beyond. As technology advances and industries continue to evolve, the demand for high-quality sealing solutions only grows stronger. The ongoing development of new rubber materials and manufacturing techniques ensures that flat rubber seal rings will remain a key player in the quest for safety, efficiency, and durability in modern engineering. By investing in high-quality flat rubber seal rings, industries can ensure the longevity and reliability of their products while minimizing downtime and maintenance costs, ultimately leading to greater profitability and customer satisfaction.

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

-

The Importance of Heavy Duty Seals in Industrial and Residential Applications

News Jul.30,2025

-

Exploring Industrial Oil Seals: From Felt Oil Seals to TTO and CFW Solutions

News Jul.30,2025

-

Essential Guide to Oil Seals: From Radial to Metal-Cased Seals for Industrial Reliability

News Jul.30,2025

-

Choosing the Right Oil Seals and Gaskets for Industrial and Automotive Applications

News Jul.30,2025

-

Cassette Seals: Durable Sealing Solutions for Harsh Environments

News Jul.30,2025

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

Products categories