Understanding TTO Oil Seal Applications and Benefits for Enhanced Machinery Performance

Understanding TTO Oil Seals A Comprehensive Overview

In the world of machinery and equipment, the role of oil seals is critical to ensure optimal performance and longevity. Among the various types of oil seals, TTO oil seals have gained widespread recognition for their reliability and efficiency. This article delves into the purpose, design, materials, and advantages of TTO oil seals, providing insight into why they are essential components in various applications.

What is a TTO Oil Seal?

TTO, which stands for Triple lip, Tapered, O-ring, represents a specific design of oil seal that features a unique triple lip configuration. This design is engineered to provide superior protection against the leakage of lubricants and contaminants. TTO oil seals are commonly used in a variety of applications, including automotive, industrial machinery, and agricultural equipment.

The primary function of an oil seal is to prevent oil or grease from leaking out of the machinery while keeping dirt, dust, and moisture from entering. This is crucial because any contaminants can lead to premature wear and damage to the internal components, resulting in costly repairs and downtime.

Design Features

The TTO oil seal’s distinctive triple lip design enhances its sealing capabilities. The three lips work together to create a resilient barrier that is particularly effective against high-pressure conditions. The tapered shape allows the seal to fit snugly into the housing, minimizing the chances of any gaps that could lead to leakage. Additionally, the TTO oil seal is designed with flexibility in mind, allowing it to conform to the shaft’s movement while maintaining a tight seal.

Materials Used

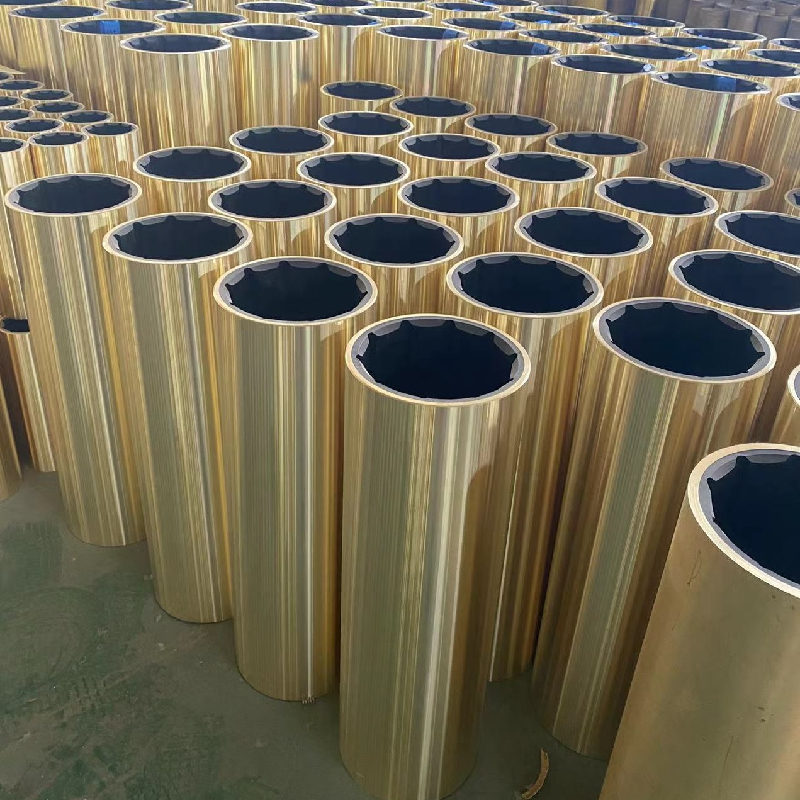

tto oil seal

TTO oil seals are typically made from high-quality elastomers like nitrile rubber, silicone, or polyurethane. Nitrile rubber is the most common material due to its excellent resistance to oil, wear, and temperature variations. Silicone seals, on the other hand, offer better performance in extreme temperatures and are also resistant to UV and ozone degradation. The choice of material influences the oil seal's durability and its ability to withstand the environmental conditions of its operating environment.

Advantages of TTO Oil Seals

1. Enhanced Sealing Performance The triple lip design ensures minimal leakage, extending the life of lubricants and preventing contaminants from entering the machinery.

2. Durability and Longevity Made from high-quality materials, TTO oil seals are built to endure harsh operating conditions, making them suitable for various applications without frequent replacements.

3. Cost-Effectiveness By preventing leaks and protecting critical components, TTO oil seals reduce maintenance costs and downtime, leading to significant savings in the long run.

4. Versatility TTO oil seals can be used in multiple applications across different industries, including automotive, aerospace, and heavy machinery. This versatility makes them a go-to choice for engineers and maintenance professionals.

Conclusion

TTO oil seals are an indispensable part of many mechanical systems, providing essential protection against leaks and contaminants. Their innovative design, coupled with durable materials, ensures effective sealing performance even under challenging conditions. Understanding the importance of TTO oil seals can lead to better maintenance practices and improved operational efficiency for various machines and equipment. Investing in high-quality TTO oil seals is not just a choice; it is a commitment to maintaining the integrity and functionality of critical machinery, ultimately contributing to greater productivity and reliability in any industrial setting.

-

Understanding the Importance of the Crankshaft Oil Seal in Engine Performance

News Jun.16,2025

-

The Unsung Heroes of Engine Protection: Understanding Automotive Shaft Seals and Oil Seals

News Jun.16,2025

-

Keeping the Engine Tight: The Role of Crankshaft Seals and Gaskets in Oil Control

News Jun.16,2025

-

Complete Protection in Harsh Conditions: A Deep Dive into Cassette Seals

News Jun.16,2025

-

Choosing the Right Oil Seal: A Guide to Trusted Brands and Suppliers

News Jun.16,2025

-

Advanced Sealing Technologies: Exploring the Range of Modern Oil Seals

News Jun.16,2025

-

Your Essential Guide to Car Repair Kits: From Rust to Dings

News Jun.13,2025

Products categories