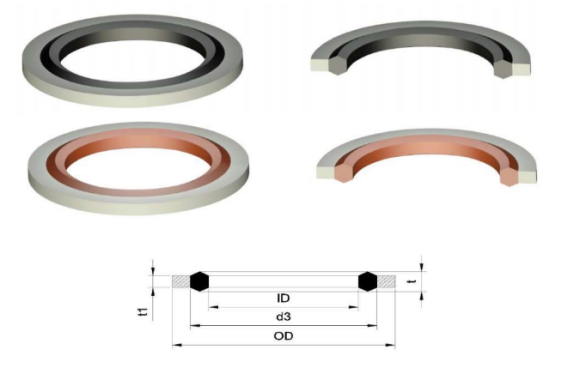

oil washer

The Importance of Oil Washers in Modern Machinery

In the ever-evolving world of technology and engineering, oil washers play a vital role in ensuring the efficiency and longevity of machinery. An oil washer, often overlooked in the grand scheme of industrial components, serves as a critical element in various applications involving engines, hydraulic systems, and other machinery that depend on lubrication to function correctly.

What is an Oil Washer?

An oil washer is a mechanical component designed to seal and retain oil within a system, preventing leaks and contamination. Typically made from materials such as rubber, plastic, or metal, these washers come in various shapes and sizes. Their primary function is to provide a fluid-tight seal around a shaft or a connection point, thereby minimizing the risk of oil leakage which can lead to significant operational failures.

Why Are Oil Washers Important?

1. Preventing Leaks One of the primary functions of oil washers is to prevent oil leaks in machinery. Leaks can lead to a decrease in lubricant levels, which can cause friction and wear on moving parts. This wear often results in costly repairs and extended downtime, which can significantly impact productivity. By using oil washers, these risks are mitigated, allowing machinery to operate smoothly.

2. Enhancing Efficiency When lubricants are contained properly within the system, machinery can operate at optimal efficiency. Oil washers ensure that lubricants do not degrade due to exposure to external contaminants such as dust or water, preserving their performance qualities. Thus, they play an indirect role in improving the overall efficiency of a machine, leading to potential savings in fuel and maintenance costs.

oil washer

3. Reducing Maintenance Costs The longevity of machinery is closely tied to how well lubrication systems function. Regular maintenance to address leaks or oil loss can be expensive and time-consuming. Oil washers help minimize these maintenance needs by maintaining proper oil levels and ensuring that the lubricants remain clean and uncontaminated. This reduction in maintenance translates to lower operational costs and increased profitability.

4. Environmental Protection Oil spills and leaks can have a detrimental impact on the environment. In industries that deal with heavy machinery and vehicles, oil leaks pose a serious risk to local ecosystems. By using high-quality oil washers, companies can significantly reduce their environmental footprint. This proactive approach not only adheres to environmental regulations but also demonstrates corporate responsibility.

Choosing the Right Oil Washer

Selecting the appropriate oil washer involves understanding the specific requirements of the machinery in question. Factors such as temperature tolerance, compatibility with different oils, and the pressure conditions within the system are crucial when making a decision. Investing in high-quality washers tailored to specific applications can yield benefits far beyond the initial expenditure.

Conclusion

In conclusion, the importance of oil washers in machinery cannot be overstated. These vital components serve as the unsung heroes in maintaining the integrity of lubrication systems across various industries. By preventing leaks, enhancing efficiency, reducing maintenance costs, and aiding in environmental protection, oil washers contribute significantly to the smooth operation of machinery. As industries continue to innovate and push the boundaries of technology, the role of oil washers will remain indispensable in ensuring sustainable and efficient machinery operation for years to come.

-

oil-drain-plug-washer-reusable-types

News Aug.22,2025

-

oil-drain-plug-replacement-guide

News Aug.22,2025

-

heavy-duty-seal-waterproof-features

News Aug.22,2025

-

engine-oil-seals-installation-guide

News Aug.22,2025

-

seal-oil-for-sale-high-temperature-grade

News Aug.22,2025

-

cassette-seal-compact-design

News Aug.22,2025

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

Products categories