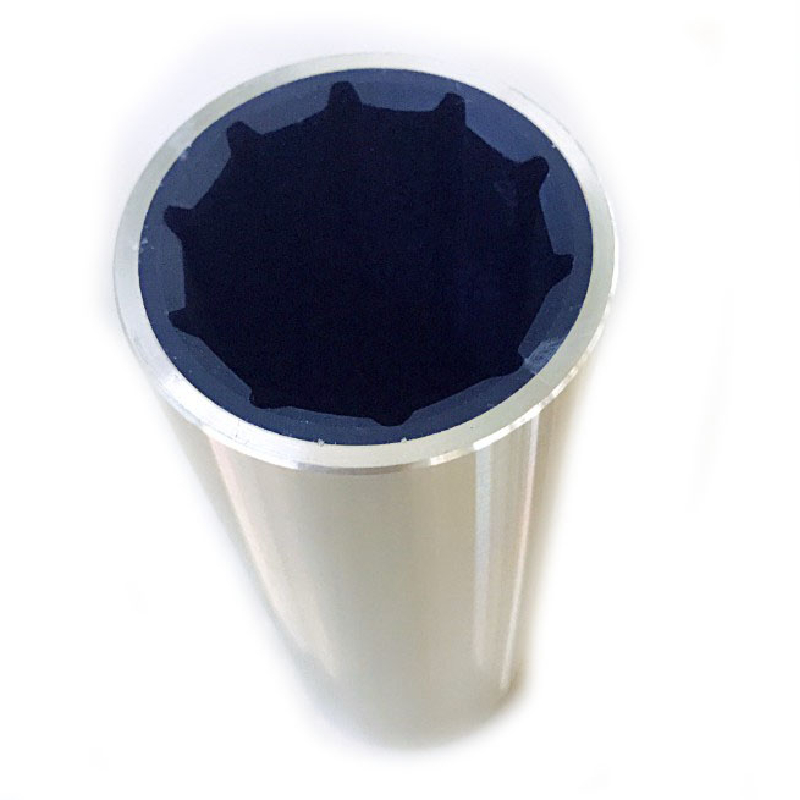

manual shaft seal

Understanding Manual Shaft Seals Importance, Types, and Applications

Shaft seals play a crucial role in machinery and equipment by preventing the leakage of fluids and contaminants from one compartment to another. They are essential components in various applications, ensuring optimal performance and longevity of machinery. Among the many types of shaft seals available, manual shaft seals are widely used due to their straightforward design and ease of maintenance. This article delves into the importance, types, and applications of manual shaft seals.

Importance of Manual Shaft Seals

Manual shaft seals are designed to create a barrier between moving and stationary components, effectively sealing the area where the shaft penetrates a housing or casing. Their primary function is to prevent the escape of lubricants and oils while also blocking external contaminants such as dirt, dust, and water from entering the machinery. This protective function is vital for several reasons

1. Preventing Fluid Leakage Fluid leaks can lead to significant losses in efficiency and performance. In industries where lubricants are crucial for machinery operation, a manual shaft seal prevents wastage and reduces maintenance costs.

2. Reducing Contamination The intrusion of dirt and moisture can cause severe damage to moving parts, reducing their lifespan. A reliable shaft seal protects the internal components, ensuring they operate smoothly.

3. Enhancing Equipment Longevity By preventing leaks and contamination, manual shaft seals contribute significantly to the longevity of machinery. This ensures that equipment operates reliably over time, reducing the frequency of repairs and replacements.

4. Maintaining Performance In many industrial applications, maintaining the correct levels of lubrication is critical to performance. Manual shaft seals help in maintaining these necessary levels, ensuring that machinery operates at peak efficiency.

Types of Manual Shaft Seals

Manual shaft seals come in various types, each designed for specific applications and requirements. The most common types include

1. Lip Seals These seals consist of a flexible lip that contacts the shaft. They provide a dynamic seal that can accommodate slight misalignments and variations in shaft diameter. Lip seals are commonly used in automotive applications and industrial machinery.

2. V-Rings A V-ring seal is designed to fit over the shaft and is in continuous contact with the housing. It protects against the ingress of dirt and moisture while retaining lubricants. V-rings are often used in rotating or reciprocating applications.

manual shaft seal

3. O-Rings These are circular seals that fit into a groove and provide a tight seal between two surfaces. O-rings are versatile and can be used for both static and dynamic sealing applications.

4. Mechanical Seals Common in high-pressure applications, mechanical seals consist of two faces that slide against each other, creating a barrier. While more complex, they offer a high level of sealing efficiency.

5. Packing Seals These are compressible materials that fill the gap between the shaft and the housing. Packing seals are often used in pumps and valves where there is rotational or reciprocating motion.

Applications of Manual Shaft Seals

Manual shaft seals are utilized in a wide array of industries and applications, including

1. Automotive Car engines rely heavily on effective shaft seals to keep oil in and contaminants out, ensuring reliable performance and engine longevity.

2. Industrial Machinery In manufacturing plants, machinery such as conveyors, pumps, and gearboxes use manual shaft seals to maintain operational efficiency and prevent leaks.

3. Aerospace Seals used in aerospace applications must withstand extreme conditions, and manual shaft seals help ensure the functionality of critical systems.

4. Marine Equipment Boats and ships, where exposure to water is constant, depend on manual shaft seals to prevent leaks and protect internal machinery.

5. HVAC Systems In heating and cooling systems, shaft seals are essential to prevent refrigerant leaks, ensuring system efficiency.

In conclusion, manual shaft seals are indispensable components in modern machinery and systems. Their role in preventing fluid leaks and contamination helps maintain equipment performance, extend lifespan, and reduce maintenance costs. Understanding the different types of manual shaft seals and their applications can aid in selecting the appropriate seal for various industrial and automotive needs, ensuring efficient and reliable operation across multiple sectors.

-

Understanding the Importance of the Crankshaft Oil Seal in Engine Performance

News Jun.16,2025

-

The Unsung Heroes of Engine Protection: Understanding Automotive Shaft Seals and Oil Seals

News Jun.16,2025

-

Keeping the Engine Tight: The Role of Crankshaft Seals and Gaskets in Oil Control

News Jun.16,2025

-

Complete Protection in Harsh Conditions: A Deep Dive into Cassette Seals

News Jun.16,2025

-

Choosing the Right Oil Seal: A Guide to Trusted Brands and Suppliers

News Jun.16,2025

-

Advanced Sealing Technologies: Exploring the Range of Modern Oil Seals

News Jun.16,2025

-

Your Essential Guide to Car Repair Kits: From Rust to Dings

News Jun.13,2025

Products categories