Understanding the Impact of Differential Seal on Performance and Longevity

Understanding Differential Seals A Key to Enhanced Performance

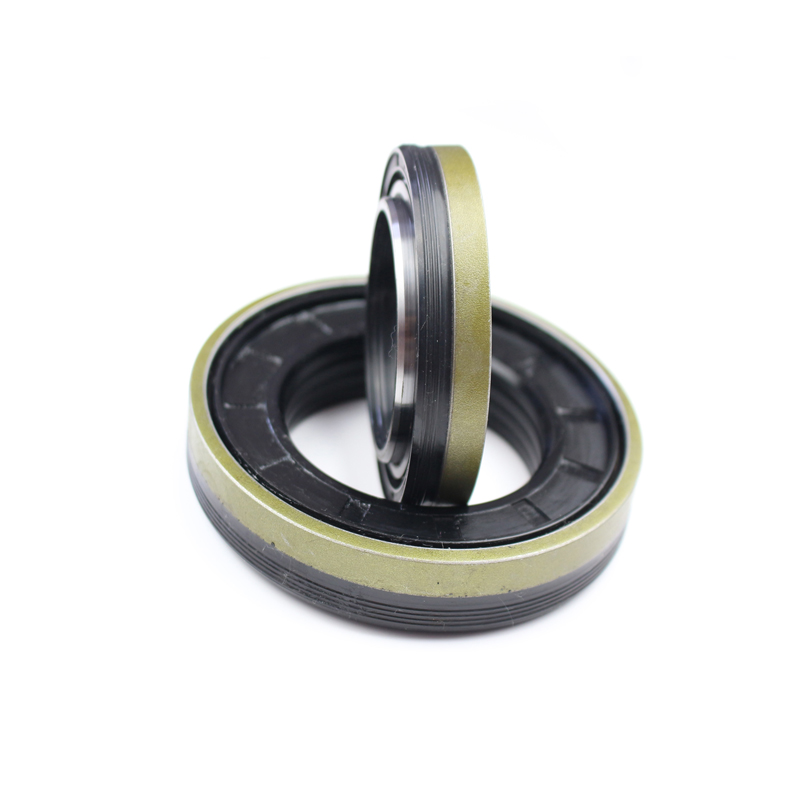

In the world of mechanical engineering and automotive performance, one component often overlooked yet crucial for the efficiency and longevity of various systems is the differential seal. This component plays a vital role in maintaining the integrity of the differential, ensuring it operates efficiently while protecting the internal components from contaminants and lubricant loss. Understanding how differential seals work, their importance, and the different types available can significantly enhance the performance of vehicles and machinery alike.

What is a Differential Seal?

A differential seal is a type of sealing mechanism strategically placed in the differential assembly of vehicles. The primary function of this seal is to contain the lubricant used to lubricate the gear set inside the differential while preventing any ingress of dirt, water, and other contaminants that could lead to mechanical failure. The differential itself is responsible for transferring power from the drive shaft to the wheels, allowing for smooth turning and optimal traction. With the high levels of stress and temperature present in these systems, the integrity of the differential seal becomes paramount.

The Importance of Differential Seals

1. Lubricant Retention One of the primary roles of differential seals is to ensure that the lubricant remains where it is needed. This lubricant reduces friction between the moving parts, minimizes wear, and dissipates heat. A failing seal can lead to lubricant leakage, resulting in inadequate lubrication, overheating, and potential mechanical failure.

2. Contaminant Prevention Differential seals help keep contaminants at bay. Dust, dirt, water, and debris can find their way into the differential if the seals are not functioning correctly. These contaminants can degrade the lubricant and wear down the gears, leading to expensive repairs and increased downtime.

3. Operational Efficiency A well-functioning differential seal contributes to the overall efficiency of the vehicle. By preventing leaks and keeping contaminants out, the differential can operate smoothly, enhancing fuel efficiency and vehicle performance.

4. Cost-Effectiveness Investing in quality differential seals can save considerable costs in the long run. By preventing oil leaks and contamination, vehicle owners can avoid costly repairs and replacements, thereby extending the lifespan of the differential and associated components.

differential seal

Types of Differential Seals

Differential seals come in various types, each designed for specific applications and performance needs

1. Rubber Seals These are the most common types of seals used in differential applications. They provide a good balance of flexibility, durability, and resistance to temperature variations.

2. Lip Seals Featuring a flexible lip that blocks contaminants, lip seals are specifically designed to retain lubricants effectively. They are widely used in automotive differentials due to their reliability.

3. Metallic Seals Often used in high-performance or heavy-duty applications, metallic seals provide excellent resistance to extreme conditions, ensuring durability and longevity even under rigorous use.

4. Composite Seals Combining various materials, composite seals aim to improve performance aspects such as wear resistance and temperature resilience, making them suitable for advanced engineering applications.

Conclusion

In conclusion, differential seals serve a critical function in ensuring the smooth operation of differential systems in vehicles and machinery. Understanding their importance can lead to better maintenance practices and informed decisions when choosing replacement seals. By prioritizing the integrity of these seals, vehicle owners and operators can enhance performance, improve efficiency, and avoid costly repairs, paving the way for a more reliable and durable operation. Ultimately, the differential seal might be a small component, but its impact on overall vehicle performance is substantial, making it a key focus for anyone interested in mechanical systems.

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

-

The Importance of Heavy Duty Seals in Industrial and Residential Applications

News Jul.30,2025

-

Exploring Industrial Oil Seals: From Felt Oil Seals to TTO and CFW Solutions

News Jul.30,2025

-

Essential Guide to Oil Seals: From Radial to Metal-Cased Seals for Industrial Reliability

News Jul.30,2025

-

Choosing the Right Oil Seals and Gaskets for Industrial and Automotive Applications

News Jul.30,2025

-

Cassette Seals: Durable Sealing Solutions for Harsh Environments

News Jul.30,2025

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

Products categories