Choosing the Right Axle Bearing Seal for Your Vehicle Maintenance Needs

Understanding Axle Bearing Seals Importance and Maintenance

Axle bearing seals play a crucial role in the smooth operation of vehicles, particularly in the automotive and industrial sectors. These seals protect the axle bearings from dirt, debris, and moisture, ensuring the longevity and performance of the axle assembly. Understanding their function, types, and maintenance can significantly improve vehicle reliability and safety.

What are Axle Bearing Seals?

Axle bearing seals are specialized components designed to prevent the ingress of contaminants into the axle bearing system while retaining lubrication. Typically made from durable materials such as rubber or various synthetic compounds, these seals are engineered to withstand environmental factors, including temperature fluctuations, exposure to chemicals, and mechanical wear.

Types of Axle Bearing Seals

1. Lip Seals These are the most common type of axle bearing seals. They consist of a flexible lip that makes contact with the shaft, creating a tight seal. Lip seals are effective at blocking dirt and moisture while retaining lubricant.

2. Labyrinth Seals These seals are designed with a series of grooves or ridges that create a tortuous path. This complexity hinders the passage of contaminants, making labyrinth seals suitable for applications that experience significant exposure to dust or dirt.

3. Umbrella Seals Often used in environments with higher contamination risks, umbrella seals resemble an umbrella and provide a broad protective area over the bearing. They allow for movement while preventing foreign particles from entering.

Importance of Axle Bearing Seals

The primary role of axle bearing seals is to ensure that axle bearings operate effectively. If contaminants enter the bearing assembly, they can lead to accelerated wear, reduced performance, and ultimately, component failure.

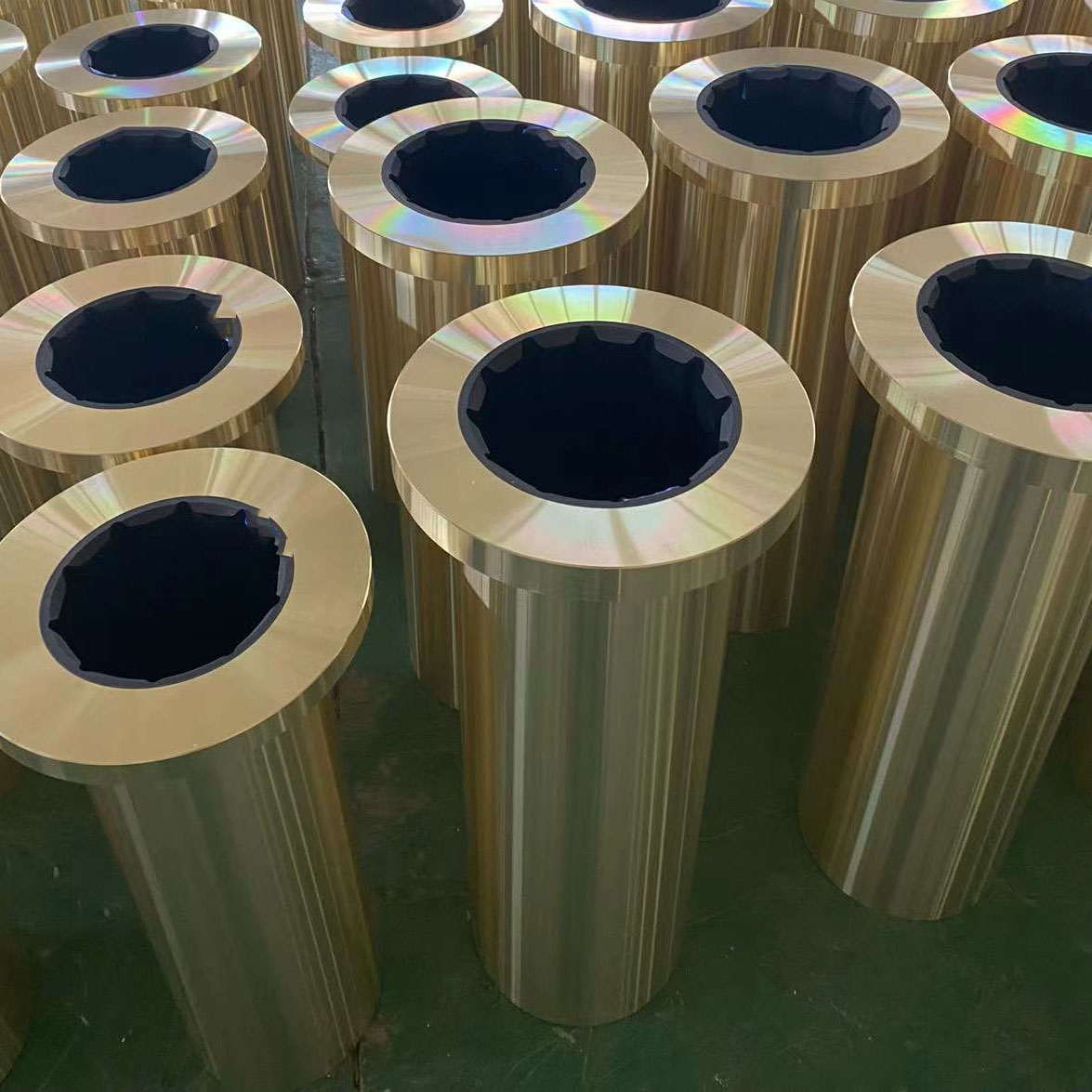

axle bearing seal

Moreover, these seals help to maintain the correct level of lubrication, which is essential for reducing friction and heat within the bearing. Proper lubrication minimizes the risk of overheating and extensive damage, ensuring that the vehicle operates efficiently.

Maintenance Tips

To prolong the life of axle bearing seals, regular maintenance is essential. Here are some tips

1. Routine Inspections Regularly inspect the axle seals for signs of wear, cracking, or leaking. Early detection can prevent more significant issues down the line.

2. Cleaning Keep the axle area clean to minimize debris that can penetrate the seals. Use a soft brush or cloth to remove dust and dirt.

3. Lubrication Ensure that the bearings are adequately lubricated. Follow the manufacturer’s guidelines for the appropriate type and frequency of lubrication.

4. Professional Assistance If you notice any significant wear or damage, seek professional help. Replacing seals promptly can save you from costly repairs in the future.

Conclusion

Axle bearing seals are a vital component in the overall performance and durability of vehicles. They offer protection against contaminants and play a significant role in lubrication retention. By understanding their importance and committing to regular maintenance, vehicle owners can enhance their vehicles' reliability and safety on the road.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories