High-Quality Oil Pump O-Rings for Reliable Sealing Performance

Understanding Oil Pump O-Rings Importance, Function, and Maintenance

In the world of automotive engineering, the oil pump is a crucial component that ensures the efficient circulation of engine oil throughout the engine. One small but significant part of the oil pump assembly is the O-ring. This unassuming component plays a vital role in maintaining the integrity and efficiency of the oil pump system. In this article, we will explore the function and importance of oil pump O-rings, as well as tips for their maintenance and replacement.

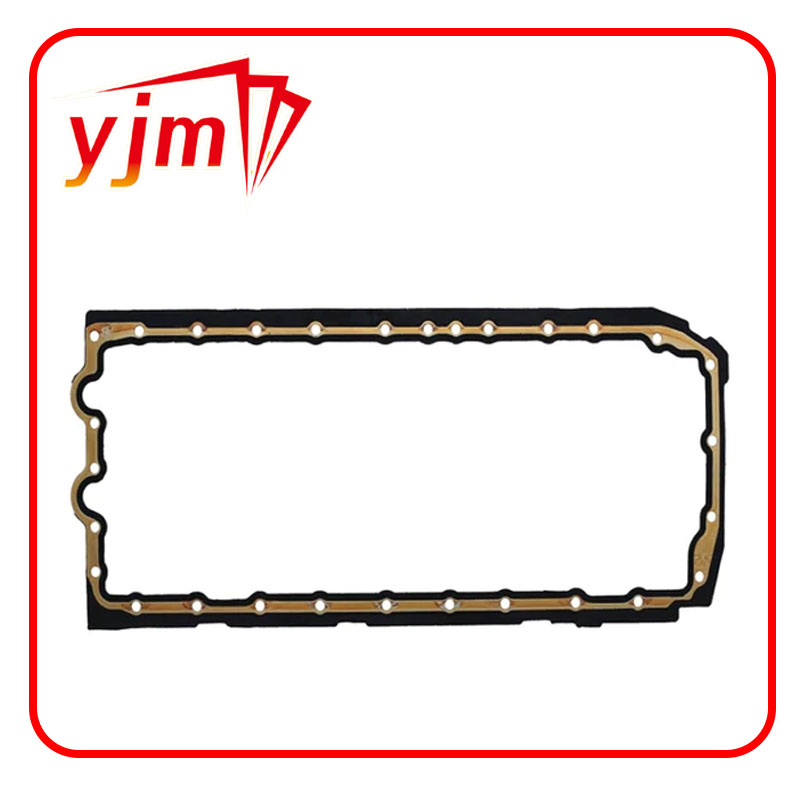

What is an Oil Pump O-Ring?

An oil pump O-ring is a circular sealing device typically made from high-quality rubber or synthetic materials. Its primary function is to provide a reliable seal between the oil pump and the engine block, preventing oil leaks that can lead to severe engine damage. O-rings are designed to withstand exposure to high temperatures and pressures, making them ideal for use in engines where oil is pumped at varying rates.

Importance of Oil Pump O-Rings

1. Prevention of Oil Leaks One of the most critical roles of the O-ring is preventing oil leaks. Oil is essential for lubricating engine components, and any loss of oil can lead to increased friction and wear, resulting in potential engine failure.

2. Maintaining Pressure The oil pump generates pressure to ensure proper oil flow. An effective O-ring helps maintain this pressure within the system, ensuring that oil reaches all necessary engine parts efficiently.

3. Enhancing Engine Performance A well-functioning oil pump and its O-ring contribute to the overall performance of the engine. By ensuring optimal oil circulation, the O-ring helps to keep the engine running smoothly and efficiently.

4. Durability and Reliability O-rings are engineered to resist wear and tear over time. Their durability is crucial for maintaining the longevity of the oil pump and, by extension, the engine itself.

oil pump o ring

Maintaining Oil Pump O-Rings

To ensure that the oil pump O-ring functions effectively, regular maintenance checks are essential. Here are some practical tips

1. Routine Inspections During routine vehicle maintenance, check the oil pump and its surrounding areas for signs of oil leaks. If you notice any oil accumulation, it may indicate a failing O-ring that requires replacement.

2. Prompt Replacement If you detect a leak or experience a drop in oil pressure, it’s essential to replace the O-ring promptly. Delaying the replacement can lead to more severe engine problems and costly repairs.

3. Using Quality Parts When replacing O-rings, always opt for high-quality parts that meet manufacturer specifications. This ensures a proper fit and optimal performance.

4. Professional Assistance If you are not comfortable inspecting or replacing the O-ring yourself, seek professional help. Mechanics have the expertise and tools necessary to ensure the job is done correctly.

Conclusion

The oil pump O-ring, though small in size, plays a monumental role in the efficiency and longevity of an engine. By understanding its importance and implementing regular maintenance practices, vehicle owners can safeguard against costly repairs and enjoy a smoother driving experience. Remember, a routine check on the oil pump O-ring can go a long way in ensuring the health of your engine.

-

The Essential Kits Every Car Owner Should Have

News May.13,2025

-

Preventing Leaks: A Guide to Common Oil and Transmission Gaskets

News May.13,2025

-

Preventing Engine Damage: How to Handle an Oil Filter Housing Leak

News May.13,2025

-

Key Gaskets That Keep Your Engine Leak-Free

News May.13,2025

-

Essential Engine Seals: A Guide to Oil Filter and Housing Gaskets

News May.13,2025

-

Choosing the Right Repair Kits for Long-Lasting Engine Performance

News May.13,2025

-

What You Need to Know About Oil Drain Plugs and Their Costs

News May.12,2025

Products categories