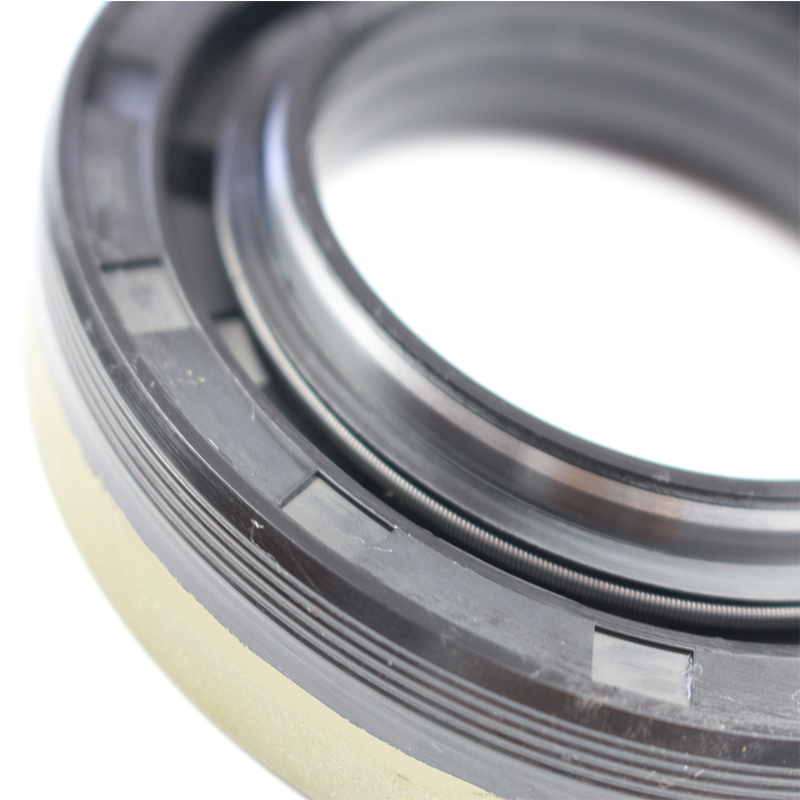

oil seal rubber

Understanding Oil Seal Rubber An Essential Component in Mechanical Engineering

Oil seals play a crucial role in various mechanical systems, and at the heart of these seals is the material known as oil seal rubber. This specialized elastomer is designed to prevent the leakage of lubricants such as oil and grease while keeping contaminants like dust and dirt at bay. In this article, we will explore the properties, applications, and advantages of oil seal rubber.

What is Oil Seal Rubber?

Oil seal rubber is specifically formulated to withstand harsh environments encountered in mechanical applications. It is commonly made from a variety of synthetic rubber compounds, including nitrile rubber (NBR), fluorocarbon rubber (FKM), and silicone rubber, each chosen for its unique properties. NBR, for instance, is renowned for its excellent resistance to petroleum oils, while FKM displays superior stability at high temperatures and offers improved chemical resistance. Silicone rubber, on the other hand, excels in applications requiring flexibility at low temperatures.

Key Properties of Oil Seal Rubber

1. Resilience Oil seal rubber is known for its ability to return to its original shape after deformation. This property is crucial for maintaining a proper seal throughout the lifespan of the component.

2. Chemical Resistance Given that oil seals are often exposed to various types of oils and chemical substances, the rubber used must resist degradation from these fluids. This ensures the longevity and reliability of the sealing application.

3. Temperature Tolerance Different applications involve varying temperature ranges. High-quality oil seal rubber can withstand both extreme heat and cold, making it suitable for a range of environments.

4. Durability Oil seal rubber is designed to endure wear and tear caused by friction and pressure. Its durability ensures that seals maintain their performance over extended periods.

Applications of Oil Seal Rubber

Oil seal rubber is utilized in a multitude of industries and applications. Some of the most common uses include

oil seal rubber

- Automotive Industry Oil seals are found in engines, gearboxes, and differentials, preventing oil leakage and protecting internal components from dust and harmful contaminants.

- Industrial Machinery In machinery such as pumps and compressors, oil seals play a vital role in maintaining the efficiency and operational integrity by ensuring the proper retention of lubricants.

- Aerospace In aircraft, oil seals prevent fluid loss from hydraulic systems, contributing to safety and reliability

.- Household Appliances Many appliances, including washing machines and refrigerators, utilize oil seals to prevent issues related to fluid leakage.

Advantages of Using Oil Seal Rubber

1. Cost-Effective When compared to metal sealing solutions, oil seal rubber is often more economical, providing effective sealing capabilities without the added cost.

2. Ease of Installation The lightweight nature and flexibility of oil seal rubber make it easier to install, reducing labor time and associated costs.

3. Maintenance-Free Once installed, oil seal rubber requires minimal maintenance. Their durability ensures that they maintain performance over time without the need for frequent replacements.

4. Versatile Design Options Oil seals can be manufactured in various shapes and sizes, meeting the specific sealing needs of diverse applications.

Conclusion

In conclusion, oil seal rubber plays a pivotal role in mechanical engineering, offering an effective solution for sealing applications across a wide range of industries. Its exceptional properties of resilience, chemical resistance, temperature tolerance, and durability make it an indispensable component. As technology continues to advance, the development of new formulations of oil seal rubber will likely yield even greater performance and reliability, further enhancing its importance in modern machinery and automotive design. Whether in an engine, hydraulic system, or industrial setting, oil seal rubber continues to be a cornerstone of effective sealing technology.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories