oil seal 20x32x6

Understanding Oil Seals A Detailed Look at the 20x32x6 Specification

Oil seals, also known as rotary shaft seals, play a vital role in various engineering applications by preventing the leakage of oils and lubricants from machinery. One such specification, the oil seal measuring 20x32x6, is widely used in different sectors, including automotive, industrial, and aerospace industries. This article delves into the essential aspects of this specific oil seal, its importance, construction, and applications.

What is an Oil Seal?

An oil seal is a mechanical device that typically consists of a rubber or elastomeric material. Its primary function is to retain lubricants and prevent contaminants from entering the machinery. It is placed at the interface between the stationary and moving parts, creating a barrier that enhances the operational efficiency and longevity of machines.

The 20x32x6 Specification

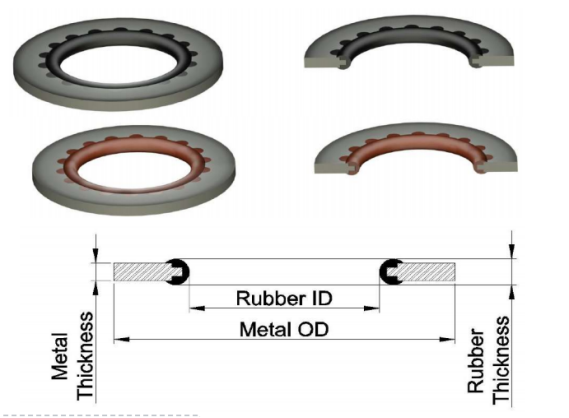

The numbers in the designation 20x32x6 represent the dimensions of the oil seal - 20 mm - The inner diameter (ID) of the seal. - 32 mm - The outer diameter (OD) of the seal. - 6 mm - The thickness of the seal.

These specifications are crucial as they determine the fit and functionality within a specific assembly. For instance, the 20 mm inner diameter is designed to fit snugly around a shaft, while the 32 mm outer diameter ensures that it can be seated properly in a housing.

Construction Materials

Oil seals are typically made from a variety of materials, including - Nitrile Rubber (NBR) NBR oil seals are highly resistant to petroleum-based oils and greases, making them ideal for a range of applications. - Fluorocarbon Rubber (FKM) These seals have higher temperature and chemical resistance and are often used in more extreme conditions. - Polyurethane This material offers excellent wear resistance and flexibility, making it suitable for dynamic applications.

oil seal 20x32x6

The choice of material largely depends on the specific application requirements, including temperature, chemical exposure, and operating conditions.

Importance of Oil Seals

Oil seals serve several critical functions in machinery 1. Leak Prevention They maintain the integrity of lubricants, preventing leaks that could lead to inadequate lubrication and increased wear on components. 2. Contamination Control Oil seals block foreign particles, such as dirt and dust, from entering the machinery, which could otherwise lead to operational failures. 3. Efficiency Improvement By keeping lubricants where they belong, oil seals contribute to the overall efficiency of machinery, reducing energy consumption and increasing reliability.

Applications of the 20x32x6 Oil Seal

The 20x32x6 oil seal is commonly found in various applications, including - Automotive In vehicles, these oil seals are used in engines, transmissions, and differential assemblies. They help maintain the proper oil levels necessary for smooth vehicle operation. - Industrial Machinery Many types of industrial equipment, including pumps, gearboxes, and compressors, utilize oil seals to ensure optimal performance and protect against lubricant loss. - Aerospace In the aerospace sector, specific oil seals like the 20x32x6 are critical for ensuring the reliability and safety of aircraft systems.

Selecting the Right Oil Seal

When choosing an oil seal, several factors must be taken into account - Operating Conditions Consider the temperature, pressure, and type of lubricants involved in the application. - Material Compatibility Ensure that the material of the oil seal is compatible with the fluid it will be sealing. - Size Always validate dimensional requirements to ensure a proper fit within the assembly.

Conclusion

In summary, the 20x32x6 oil seal plays a significant role in various applications across multiple industries. Its primary functions of preventing leakage, controlling contamination, and enhancing efficiency are crucial for the longevity and reliability of machinery. Understanding the specifications and characteristics of oil seals can help engineers and maintenance professionals make informed choices, thereby ensuring optimal performance in their respective applications. Whether in automotive, industrial, or aerospace settings, the importance of a reliable oil seal cannot be overstated, as it directly impacts the efficiency and safety of machinery.

-

Oil Drain Plug Washer Reusable Types

News Aug.22,2025

-

Oil Drain Plug Replacement Guide

News Aug.22,2025

-

Heavy Duty Seal Waterproof Features

News Aug.22,2025

-

Engine Oil Seals Installation Guide

News Aug.22,2025

-

Seal Oil for Sale High Temperature Grade

News Aug.22,2025

-

Cassette Seal Compact Design

News Aug.22,2025

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

Products categories