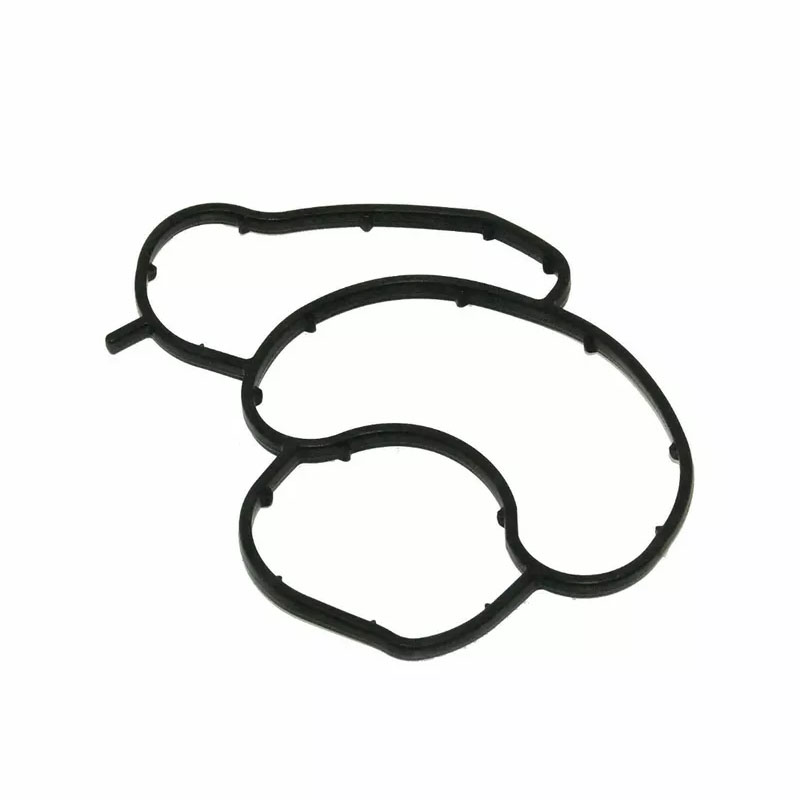

High-Quality Oil Seal 12 22 7 - Durable and Reliable Sealing Solution

Understanding Oil Seals The 12 22 7 Specification

Oil seals, often referred to as shaft seals or rotary seals, play an essential role in various mechanical systems, preventing the leakage of lubricants and contaminants. These seals are crucial in ensuring the efficiency and longevity of machinery in numerous industries, including automotive, aerospace, and industrial manufacturing. Among the various specifications available, the oil seal labeled 12 22 7 stands out, representing specific dimensions and applications.

Understanding Oil Seals The 12 22 7 Specification

Oil seals are typically made from a variety of materials, including rubber, silicone, and sometimes even metal, depending on the intended application and the type of fluids they will encounter. The material choice is crucial, as it impacts the seal's durability, resistance to chemical degradation, and ability to withstand different temperatures. For the 12 22 7 oil seal, a high-quality elastomer is often used to ensure it can withstand the mechanical stresses while effectively sealing against oil and other lubricants.

oil seal 12 22 7

In practical applications, an oil seal like the 12 22 7 might be utilized in automotive engines, gearboxes, or hydraulic systems, where preventing fluid loss is essential. When oil leaks occur, not only can this lead to decreased efficiency, but it can also result in significant damage to the machinery over time, leading to costly repairs and downtime. Therefore, the importance of selecting the appropriate oil seal cannot be overstated.

Furthermore, the installation of the oil seal must be carried out with precision. Misalignment or damage during installation can compromise its effectiveness. It is essential to ensure that the sealing surfaces are clean and free of debris, and that the seal is properly seated in its housing to achieve optimal performance.

In summary, understanding the specifications and applications of oil seals like the 12 22 7 variant is crucial for anyone involved in machinery maintenance or engineering. These small yet significant components are vital for the smooth operation of complex systems, underscoring the importance of proper selection, installation, and maintenance to avert potential machinery failures. As technology advances, the design and materials used in oil seals will continue to evolve, leading to improved performance and reliability across various sectors.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories