Navigating Marine Bearings: Key Components for Smooth Sailing and Towing

Marine systems rely on precision-engineered components to operate effectively, whether you're towing your boat or navigating open waters. Among the most essential are marine wheel bearings, outboard bearing carriers, rubber cutlass bearings, and other specialized parts like the rudder shaft bearing and ship propeller shaft bearing. Understanding these components and maintaining them properly is crucial for performance, safety, and longevity. This article explores the vital functions and care of six key marine bearings.

Towing Essentials: Marine Wheel Bearings and Packing Procedures

One of the most critical components for boat transport is the marine wheel bearing. Found inside the hubs of trailer wheels, these bearings reduce friction and allow for smooth wheel rotation under heavy loads and varying road conditions. Due to frequent exposure to water—especially saltwater—these bearings must be well-protected and regularly maintained.

Proper maintenance includes packing boat trailer bearings, a process that involves removing the old grease, cleaning the bearings, inspecting for damage, and applying fresh marine-grade grease. This task should be done:

At the beginning and end of each boating season

After long trips or extended water exposure

Anytime signs of overheating or grinding occur

Packing boat trailer bearings ensures they’re fully lubricated and less prone to rust or failure. For added protection, many boaters install bearing protectors, which keep water out and grease sealed in.

Neglecting your marine wheel bearings can lead to catastrophic trailer failure, leaving you stranded or causing accidents. Routine inspection and proper packing are non-negotiable.

Critical Waterborne Bearings: Outboard, Cutlass, and Rudder Bearings

Once your boat is in the water, other types of marine bearings take over. Each plays a specific role in propulsion, steering, or structural support.

Outboard Bearing Carrier

An outboard bearing carrier is located in the lower unit of an outboard motor. It houses the propeller shaft bearing and helps maintain alignment between the prop shaft and the engine. These carriers also hold oil seals, keeping gear oil in and water out.

Key features of a good outboard bearing carrier include:

High corrosion resistance

Precision-fit for propeller shaft stability

Easy access for servicing prop shaft bearings and seals

Signs of wear may include vibration, noise, or gear oil leakage—any of which could indicate a failing outboard bearing carrier or associated bearings.

Rubber Cutlass Bearing

The rubber cutlass bearing—also spelled “cutless”—is one of the most common shaft bearings in marine vessels. Found in the strut or stern tube, it supports the rotating propeller shaft while allowing water to act as a lubricant and coolant. Its durable rubber lining features grooves that channel water around the shaft.

Advantages of a rubber cutlass bearing:

Quiet and vibration-dampening operation

Environmentally friendly (uses seawater lubrication)

Durable under high loads and harsh conditions

These bearings should be checked routinely for signs of wear, especially if you notice increased vibration or shaft noise.

Rudder Shaft Bearing

The rudder shaft bearing supports the vertical shaft that connects the steering wheel or system to the rudder itself. This bearing enables smooth pivoting as the boat turns and helps keep the rudder aligned and stable.

Signs that your rudder shaft bearing needs attention:

Difficulty turning the helm

Excessive play in the rudder

Strange noises during maneuvering

Maintaining this bearing is critical, especially on larger boats or those that navigate strong currents where precise steering is essential.

Power Transmission: Ship Propeller Shaft Bearings

At the heart of a vessel's propulsion system lies the ship propeller shaft bearing. These are heavy-duty marine bearings designed to handle both radial and axial loads as the propeller turns and drives the vessel forward. These bearings must resist:

Extreme rotational forces

Varying temperatures

Saltwater corrosion

Types of ship propeller shaft bearings include:

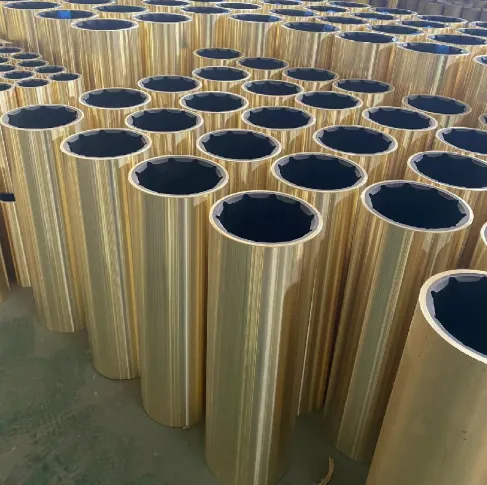

Sleeve bearings made from bronze, composite, or rubber

Thrust bearings that absorb axial forces

Water-lubricated bearings, such as the cutlass bearing

The performance of these bearings is crucial for the engine's energy to be efficiently transferred to the water. Even slight misalignment or degradation can result in loss of speed, increased fuel consumption, and long-term damage to the propulsion system.

Routine alignment checks, shaft inspections, and bearing replacements are necessary to ensure smooth operation of the ship propeller shaft bearing—especially on commercial or long-range vessels.

From highway towing to open-sea navigation, marine bearings are foundational to the performance and reliability of your boat and trailer. Whether it's packing boat trailer bearings, replacing a worn rubber cutlass bearing, or monitoring your ship propeller shaft bearing, regular maintenance and awareness are essential for every boat owner.

Reliable bearings like the marine wheel bearing, outboard bearing carrier, and rudder shaft bearing reduce mechanical stress, prevent failures, and help you enjoy your time on the water with confidence.

-

Seal 12x20x5: Precision Radial Shaft Seals for Industrial Reliability

Wararka Nov.24,2025

-

Seal 12x18x5: Essential Guide to Specifications, Applications & Vendors

Wararka Nov.24,2025

-

Understanding Seal 12 20 5: Applications, Specifications & Industry Insights

Wararka Nov.23,2025

-

Durable Oil Seal 85x110x12 – Reliable Sealing Solutions for Industry

Wararka Nov.23,2025

-

Durable and Precise Oil Seal 75x95x10 for Efficient Machinery | YJM Seal

Wararka Nov.22,2025

-

Durable Oil Seal 75x100x10 for Reliable Industrial Performance | YJM Seal

Wararka Nov.22,2025

-

High-Quality Oil Seal 65x90x10 | Durable & Reliable Sealing Solutions

Wararka Nov.22,2025

Qaybaha alaabta