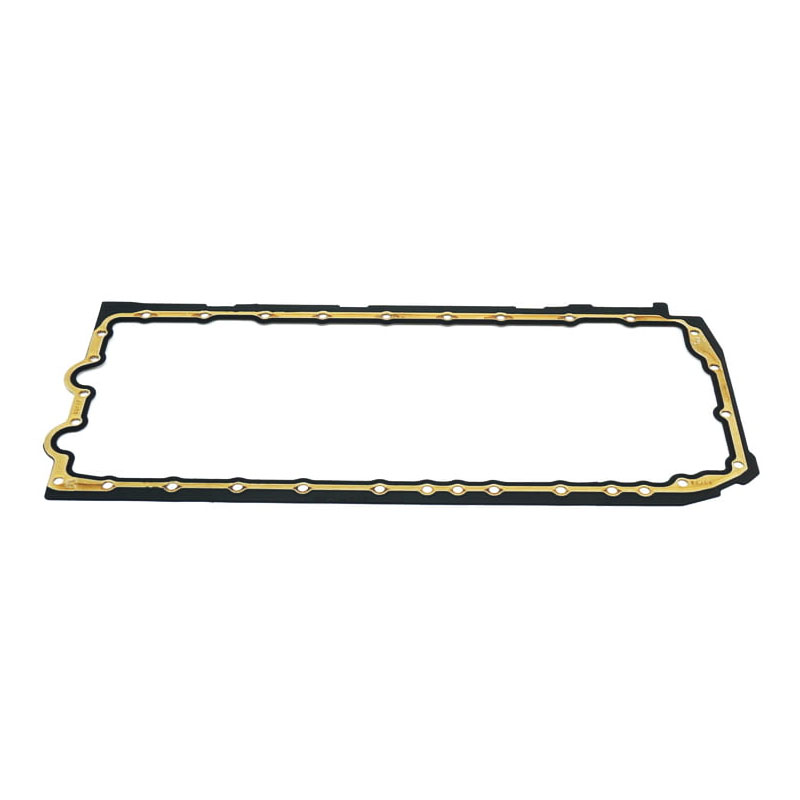

bonded seal ring

Understanding Bonded Seal Rings Their Importance and Application

In the world of mechanical engineering and sealing technology, the bonded seal ring stands out as a crucial component used in various applications to ensure leak-free systems. A bonded seal ring combines the functionalities of a metallic washer and an O-ring, providing an innovative solution for sealing joints in a range of environments. This article aims to explore the structure, advantages, applications, and materials involved in bonded seal rings.

Structure and Design

A bonded seal ring typically consists of a flat metallic washer that has an elastomeric sealing material bonded to its inner circumference. The metal washer serves as a rigid support structure that withstands external loads and shear forces while the elastomer provides a flexible and effective sealing surface. This design allows the bonded seal ring to effectively form seals over imperfect surfaces and accommodate thermal expansions and contractions in mechanical assemblies.

The combination of metal and elastomer in the design makes bonded seal rings versatile for various applications. The metal component is often made from materials such as steel or aluminum, while the elastomer can be natural rubber, silicone, or synthetic compounds designed to withstand specific environmental conditions.

Advantages of Bonded Seal Rings

The primary advantages of bonded seal rings include

1. Improved Sealing Performance The dual-component design enhances sealing capabilities, allowing for effective sealing against fluids and gases under pressure.

2. Ease of Installation Unlike traditional O-ring seals that require precise sizing and handling, bonded seal rings are easy to install. Their rigid interface simplifies the assembly process.

3. Versatility Bonded seal rings are suitable for a wide range of applications across industries such as automotive, aerospace, construction, and oil and gas. Their ability to withstand diverse environmental factors makes them a preferred choice in many scenarios.

bonded seal ring

5. Durability High-quality bonded seal rings are designed to resist wear, compressibility, and deformation, ensuring long service life and performance stability even in harsh conditions.

Applications

Bonded seal rings find their application in various sectors, including

- Automotive Industry They are commonly used in engine components, transmission systems, and hydraulic systems to prevent oil and coolant leaks.

- Aerospace In aircraft and spacecraft, bonded seal rings are critical for ensuring that fuel systems function correctly without leaks that can cause hazardous situations.

- Oil and Gas The exploration and production of oil and gas rely on robust sealing solutions to prevent spills and leaks in pipelines and drilling equipment.

- Hydraulic Systems In pumps and valves, these seal rings ensure tight sealing, contributing to the efficient operation of hydraulic machinery.

- Industrial Machinery Various machines and equipment utilize bonded seal rings to prevent contamination and ensure the reliability of operations across diverse environments.

Material Selection

The effectiveness of bonded seal rings is heavily dependent on the materials used in their construction. It’s crucial to select materials that not only provide the necessary mechanical properties but also exhibit good chemical resistance. For instance, in environments where high temperatures and aggressive chemicals are present, fluoroelastomers may be chosen for their exceptional resistance.

In conclusion, bonded seal rings are an essential component in the realm of sealing technology. Their innovative design, coupled with their numerous advantages, makes them a reliable choice for ensuring leak-free operations across multiple industries. As technology advances, the need for more efficient and durable sealing solutions will continue to grow, solidifying the role of bonded seal rings in engineering design and application. As industries evolve and face new challenges, bonded seal rings will remain a pivotal element in achieving operational efficiency and safety.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories