Exploring the Specifications and Applications of Seal 2016x26x7 in Various Industries

Understanding the Significance of Seal 2016x26x7 in Modern Applications

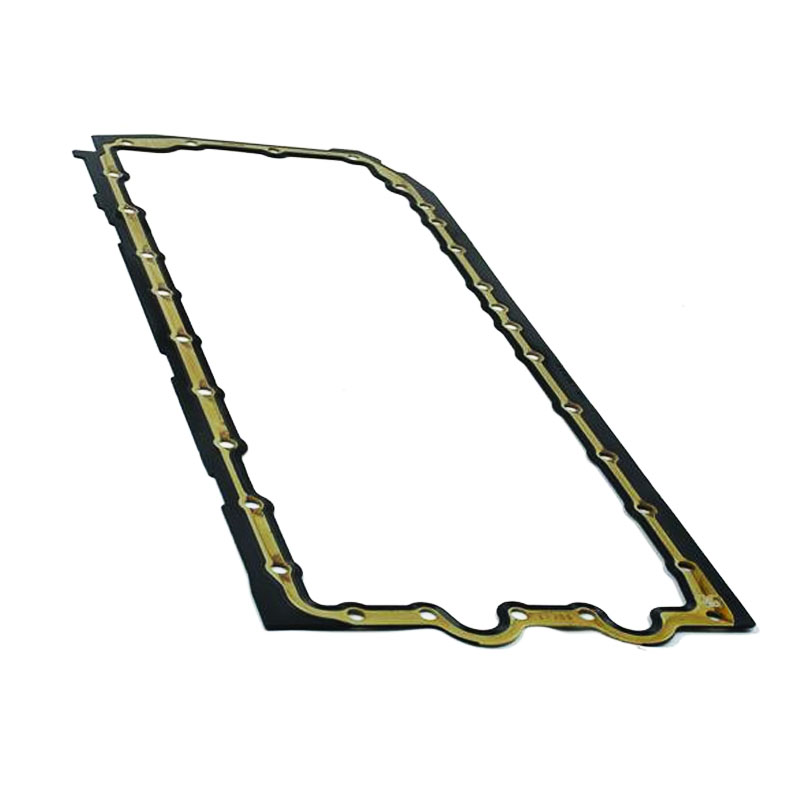

In many industries, seals play a crucial role in ensuring efficiency, safety, and functionality. Among the numerous specifications of seals available today, the Seal 2016x26x7 has gained attention due to its specific dimensions and applications. This article delves into what this seal specification means, its materials, types, and various sectors where it is commonly utilized.

What Does 2016x26x7 Mean?

The designation 2016x26x7 refers to the dimensions of the seal. The first two numbers (20 and 16) indicate the inner and outer diameters of the seal, respectively. In this case, the inner diameter is 20 mm, and the outer diameter is 26 mm. The final number (7) represents the seal’s thickness in millimeters. These measurements matter significantly, as they determine the compatibility of the seal with the mechanical components it will protect or aid in the functioning.

Materials Used in Seals

Seals come in various materials depending on their intended use and the environmental conditions they must withstand. Common materials for seals like the 2016x26x7 include rubber, silicone, nitrile, and Viton. Each material has distinctive properties; for instance, nitrile rubber is often used in applications involving petroleum products, while silicone seals are favored for high-temperature applications due to their thermal stability.

The choice of material influences not only the seal's performance but also its longevity. For example, Viton seals are known for their chemical resistance and durability, making them ideal for applications in the automotive industry where exposure to harsh fluids occurs.

seal 16x26x7

Applications of Seal 2016x26x7

The 2016x26x7 seal is widely applicable across various sectors. In the automotive industry, this seal can effectively prevent fuel and oil leakage, ensuring that engine performance is not compromised. Seals are also essential in hydraulic systems where they prevent fluid loss and ensure efficient power transfer.

In manufacturing, machinery components require reliable seals to prevent contamination from dust and other particulates that could impair efficiency. The seal also plays a critical role in keeping lubricants contained, reducing friction, and extending the life of the machinery.

Moreover, in the field of electronics, seals are used to protect sensitive components from moisture and dust, thereby improving the reliability of devices. In HVAC (heating, ventilation, and air conditioning) systems, seals help maintain pressure, contributing to energy efficiency.

Conclusion

The Seal 2016x26x7 epitomizes a vital component used in diverse applications, from automotive to industrial machinery and electronics. Understanding its specifications and advantages ensures optimal performance and longevity of the systems they are integrated into. With advancements in materials and manufacturing processes, seals continue to evolve, improving efficiency and effectiveness across various sectors. As industries strive for greater sustainability and performance, the role of such seals will only become more pronounced, highlighting their significance in both current and future technological landscapes.

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

-

The Essential Guide to Marine Bearings and Boat Trailer Wheel Bearings

News Jul.31,2025

-

The Complete Guide to Heavy Duty Seals: Protecting Doors and Spaces Efficiently

News Jul.31,2025

-

Essential Guide to Marine Shaft Bearings and Boat Trailer Axle Bearings

News Jul.31,2025

-

Comprehensive Guide to Marine and Trailer Bearings for Safe Boating and Transport

News Jul.31,2025

-

Comprehensive Guide to Automotive Oil Seals: Protecting Your Engine and Shafts

News Jul.31,2025

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

Products categories