Understanding Semi Truck Wheel Seals for Enhanced Performance and Longevity

Understanding Semi Truck Wheel Seals Importance and Maintenance

Semi trucks are an integral part of the logistics and transportation industry, playing a crucial role in the movement of goods across vast distances. One of the critical components that ensure the proper functioning of these heavy-duty vehicles is the wheel seal. Although it may not be the most glamorous aspect of trucking, the wheel seal is vital for performance and safety.

What is a Wheel Seal?

A wheel seal is a critical component located at the hub of a semi truck's wheel. Its primary purpose is to prevent lubrication oil from leaking out of the wheel hub, while simultaneously keeping dirt, moisture, and other contaminants from entering the hub. Typically made of rubber or synthetic materials, these seals are designed to endure extreme temperatures, pressure, and environmental conditions, all while providing a reliable barrier.

Importance of Wheel Seals

The importance of wheel seals cannot be overstated. They play a significant role in ensuring the longevity and efficiency of the wheel bearings, which are crucial for smooth operation. When a wheel seal fails, it can lead to grease leakage, which not only reduces lubrication for wheel bearings but also increases the risk of overheating and premature wear. This can ultimately lead to costly repairs and even accidents.

A compromised wheel seal can also result in the accumulation of dirt and moisture within the hub, which can cause corrosion and further damage. Regularly checking and maintaining the integrity of the wheel seals is essential for ensuring the overall safety and reliability of semi trucks.

Signs of Wheel Seal Failure

Truck drivers and fleet managers should be aware of the signs of potential wheel seal failure. Common indicators include

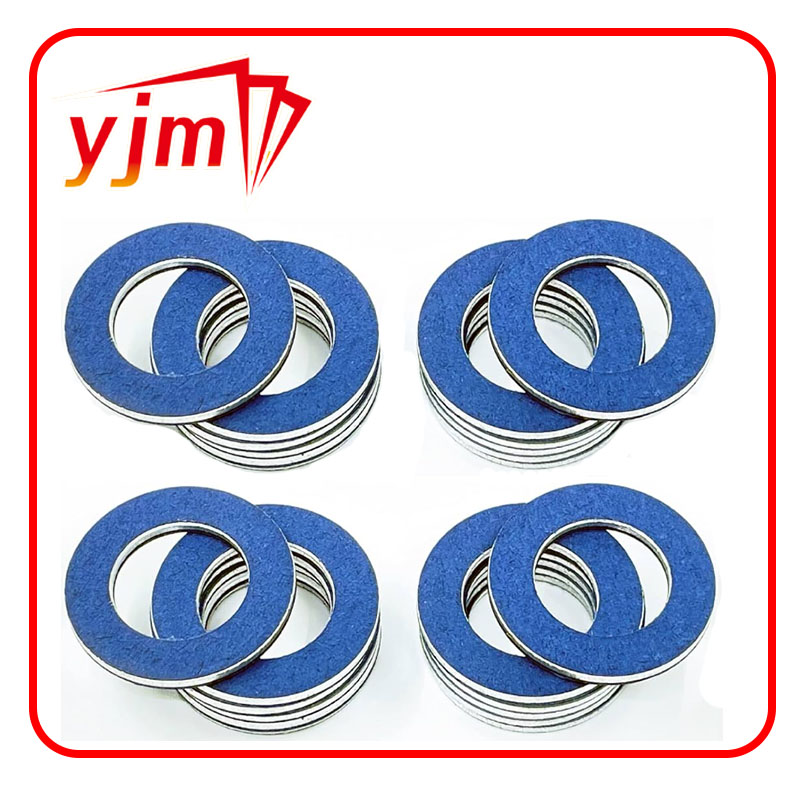

semi truck wheel seal

1. Visible Grease Leak Puddles of grease under the truck indicate that the wheel seal may be failing. 2. Unusual Noise Grinding or humming noises coming from the wheel area can signal bearing issues resulting from inadequate lubrication.

3. Increased Vibration Excessive vibration while driving could point to problems with the wheel bearings or seals.

4. Corrosion Visible rust or corrosion around the wheel hub can indicate moisture ingress due to a compromised seal.

Maintenance and Replacement

To ensure optimal performance, routine maintenance checks of the wheel seals and bearings are essential. This includes regular inspections, especially before and after long trips, and during routine maintenance intervals. If any signs of potential failure are detected, timely replacement of the wheel seals is critical.

Choosing high-quality replacement seals is also important. Investing in reliable components ensures not only the longevity of the seals themselves but also the overall performance of the truck.

Conclusion

In conclusion, the wheel seal may be a small component in the grand scheme of semi truck mechanics, but its role is indispensable. By ensuring proper function and regular maintenance of wheel seals, truck drivers and fleet operators can enhance the safety, efficiency, and lifespan of their vehicles. Understanding the importance of this vital part not only secures cargo but also promotes the well-being of everyone on the road.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories