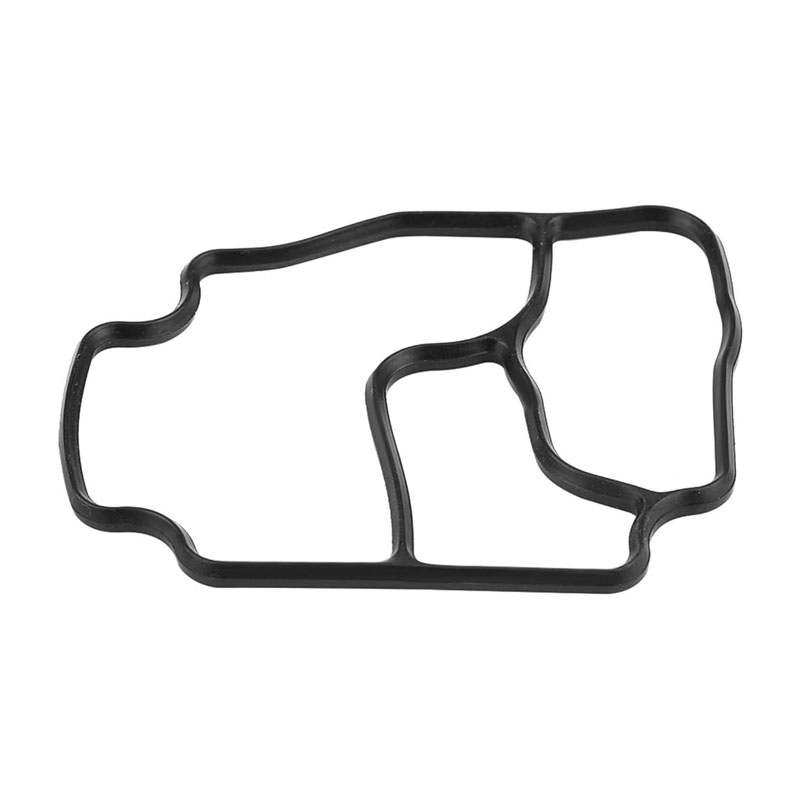

oil hub seal

The Importance of Oil Hub Seals in Modern Industries

In the realm of industrial operations, particularly within the oil and gas sector, the significance of effective sealing technologies cannot be overstated. Among the various components that facilitate the smooth functioning of oil operations, oil hub seals stand out as critical elements that ensure operational efficiency and environmental safety. This article delves into the vital role of oil hub seals, their applications, and advancements in sealing technology.

Understanding Oil Hub Seals

Oil hub seals are components engineered to prevent leaks in rotating shafts where they penetrate into oil reservoirs or systems. These seals are crucial in maintaining the integrity of oil hubs, which are essential parts of machinery such as pumps, motors, and gearboxes in oil extraction and refining processes. Designed to withstand harsh environments, oil hub seals are made from durable materials that can resist wear, high temperatures, and exposure to various chemicals.

Applications in the Oil and Gas Industry

In the oil and gas sector, oil hub seals are extensively used in drilling rigs, offshore platforms, and refineries

. Their primary function is to prevent the escape of oil and other fluids, which can lead to catastrophic environmental impacts if not properly contained. Moreover, leaks can result in significant financial losses and operational downtime due to the high costs associated with cleanup and regulatory fines.The seals also play a vital role in ensuring the reliability of equipment. For instance, in downhole tools, efficient sealing mechanisms are necessary to maintain pressure and prevent contamination of the oil supply. A malfunction in the seal can jeopardize the entire operation, making reliable seal performance a priority for operators.

Challenges and Innovations

oil hub seal

Despite their critical role, oil hub seals face several challenges. Extreme operating conditions, including high pressures, abrasive particles, and thermal fluctuations, can lead to premature seal wear and failure. As a result, operators must invest in regular maintenance and replacement of these components to avoid costly disruptions.

To address these issues, advancements in sealing technologies have emerged. Manufacturers are continuously developing new materials and designs to enhance the performance and lifespan of oil hub seals. Innovations such as polymer blends, composite materials, and advanced surface treatments are being implemented to increase resistance to wear and improve the seal’s ability to withstand the harsh conditions typical in oil and gas operations.

Moreover, the integration of smart technologies into seal systems is on the rise. These innovations include sensors that monitor seal performance in real time, providing operators with valuable data to predict potential failures before they occur. By employing predictive maintenance strategies, companies can minimize downtime, enhance productivity, and reduce costs associated with seal failures.

Environmental Considerations

With growing awareness of environmental sustainability, the importance of effective seals has taken on new dimensions. Regulatory pressure has increased, compelling companies to adopt stricter measures to contain oil spills and reduce emissions. Oil hub seals are now being designed not only for mechanical performance but also for enhanced environmental protection. Enhanced sealing solutions can directly contribute to better compliance with environmental regulations and corporate responsibility initiatives.

Conclusion

Oil hub seals may seem like small components within the vast machinery of the oil and gas industry, but their role is undeniably significant. They protect both the equipment and the environment, ensuring the safe and efficient operation of oil extraction and processing activities. As technology continues to advance, the development of more robust and efficient sealing solutions will undoubtedly play a crucial role in the future of the industry, paving the way for safer and more sustainable practices in oil and gas operations. Emphasizing the importance of these seals not only contributes to operational efficiency but also reflects a commitment to environmental stewardship in an industry where such considerations are paramount.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories