Exploring the Benefits and Applications of Oil Stem Seals in Modern Engineering Solutions

Understanding Oil Stem Seals Importance and Applications

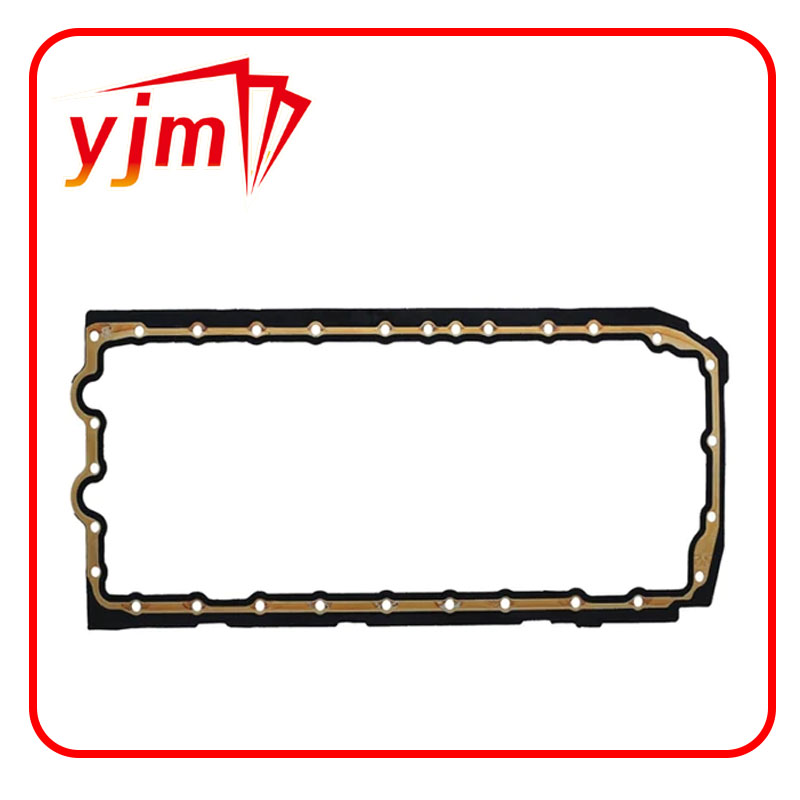

Oil stem seals are essential components in various machinery and automotive engines, playing a critical role in maintaining efficiency and performance. These seals primarily serve the purpose of preventing oil leaks, ensuring that essential fluids remain contained within the systems where they are integrated. Typically made from high-quality materials, including rubber and composite materials, oil stem seals are designed to withstand extreme temperatures, pressures, and various chemical environments.

Structure and Functionality

An oil stem seal is generally composed of a sealing lip that makes contact with the stem or shaft it encircles. The design of the seal allows it to conform to the stem's surface while creating a barrier that minimizes the escape of oil. This functionality is crucial, as even small leaks can lead to significant losses in lubricant, resulting in excessive wear and tear on engine components. In addition, oil leaks can lead to environmental concerns and increased maintenance costs.

The effectiveness of an oil stem seal depends on several factors, including material choice, design, and installation. High-quality seals made from durable materials can significantly reduce the risk of failure, ensuring a long service life. The design is equally important; it must accommodate variations in temperature and pressure while maintaining an effective seal against the dynamic movement of the stem.

Applications in Automotive Engines

In the automotive industry, oil stem seals are commonly used in engines, particularly around areas where shafts and stems exit the engine block, such as crankshafts and camshafts. These seals ensure that the oil remains in place, preventing it from leaking out into the environment and allowing for optimal lubrication of moving parts.

oil stem seals

While the primary function of oil stem seals is to prevent oil leakage, they also play a crucial role in maintaining the overall efficiency of the engine

. An efficient oil seal ensures that there is sufficient oil pressure, which helps in cooling engine parts, reducing friction, and improving overall fuel efficiency. Thus, the health of oil stem seals directly impacts vehicle performance.Maintenance and Replacement

Like any mechanical component, oil stem seals may wear out over time. Factors such as exposure to high temperatures, age, and chemical degradation can compromise their integrity. It is advisable for vehicle owners and operators to regularly inspect and monitor these seals as part of routine maintenance. Signs of failing oil stem seals may include oil spots under the vehicle, visible oil leakage around the engine, and even decreased engine performance.

Replacing worn or faulty oil stem seals is essential to prevent more extensive damage to the engine and other components. The replacement process often involves disassembling parts of the engine, which requires a skilled technician to ensure that the new seals are installed correctly. Using high-quality replacement seals can enhance the longevity of the engine and maintain its performance.

Conclusion

In summary, oil stem seals are vital components that significantly contribute to the performance and longevity of engines and machinery. Their ability to prevent oil leaks not only protects against environmental harm but also enhances engine efficiency and performance. Regular inspection and timely replacement of oil stem seals are critical in maintaining the health of mechanical systems, ensuring they operate efficiently for years to come. As technology advances, the materials and designs of oil stem seals continue to improve, leading to even greater reliability and performance in various applications.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories