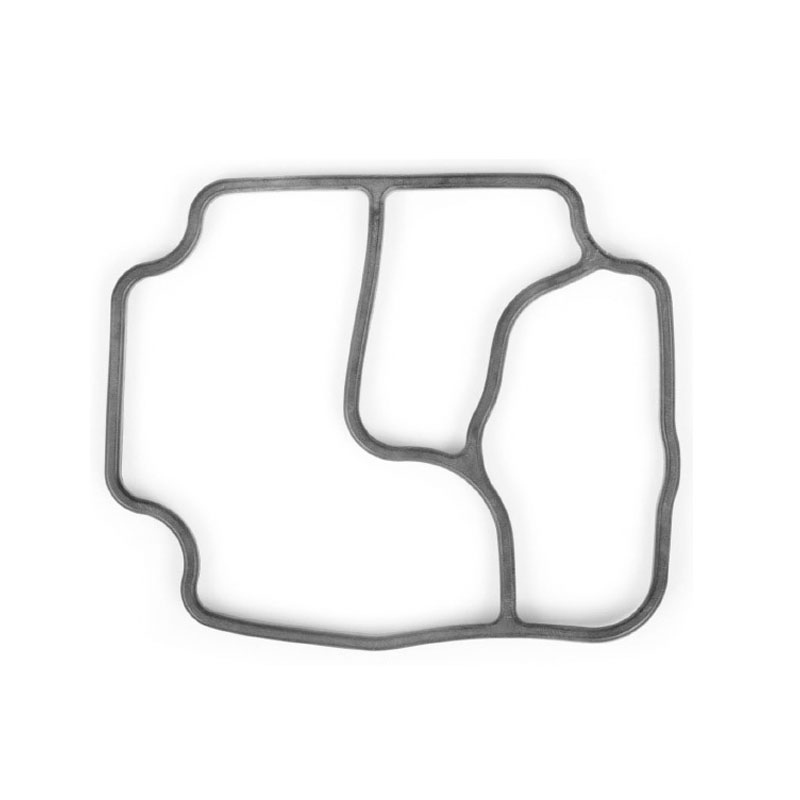

centrifugal pump seal

Understanding Centrifugal Pump Seals Function and Importance

Centrifugal pumps are widely used in various industries for transporting fluids due to their efficiency and reliability. However, one critical component that often goes unnoticed is the pump seal. The seal is essential for maintaining the integrity and performance of a centrifugal pump, and understanding its function and importance can lead to better maintenance practices and increased pump longevity.

Function of Centrifugal Pump Seals

The primary function of a centrifugal pump seal is to prevent the leakage of fluids from the pump casing, particularly at the shaft where it exits the pump. This is crucial not only for maintaining the efficiency of the pump but also for ensuring safety and environmental compliance. Different types of seals are used in centrifugal pumps, including mechanical seals, packing seals, and magnetic seals.

Mechanical seals are the most commonly used type in modern centrifugal pumps. They consist of two flat surfaces—one fixed and the other rotating—held together by springs. This design efficiently prevents fluid from leaking while allowing for the necessary movement of the pump shaft. Packing seals, on the other hand, utilize a set of braided fibers that are compressed around the shaft, creating a barrier against leaks. While packing seals may be easier to install and replace, they can require more frequent maintenance.

Importance of Proper Sealing

centrifugal pump seal

The importance of proper sealing cannot be overstated. Inadequate sealing can lead to a variety of issues, including fluid loss, decreased efficiency, and increased energy consumption. Furthermore, leaks can pose significant risks to health and safety, particularly in industries dealing with hazardous materials. Environmental regulations increasingly demand stringent controls on fluid leaks, making effective sealing a compliance requirement.

Additionally, poor sealing can result in increased wear and tear on the pump components. For example, excessive leakage can lead to overheating of the pump and subsequent damage to bearings and other parts, resulting in costly repairs and downtime. Therefore, ensuring that the pump seal is in good condition and properly maintained is vital for the overall health of the centrifugal pump.

Maintenance and Best Practices

To ensure the longevity and reliable performance of centrifugal pump seals, routine maintenance is essential. This includes regular inspections for wear and tear, leakage, and other signs of damage. It is also crucial to monitor the operating conditions, including pressure and temperature, as extreme conditions can adversely affect seal performance.

When replacing seals, selecting the right type for the specific application is important. Factors such as fluid type, temperature, pressure, and the presence of solids should be considered to minimize the risk of premature seal failure.

In conclusion, centrifugal pump seals are vital components that ensure the efficient operation of pumps across various applications. Understanding their function and maintaining them properly can prevent leakages, enhance performance, and ensure compliance with safety and environmental standards. Investing in high-quality seals and following best maintenance practices will ultimately lead to more reliable and cost-effective pump operations.

-

Understanding Marine Bearings: The Key to Smooth Sailing and Safe Trailering

News May.08,2025

-

Understanding Critical Gaskets in Oil System Maintenance: From DT466 to 7.3 Powerstroke

News May.08,2025

-

Essential Guide to Marine Bearings and Trailer Hubs: Ensuring Safe Navigation and Transport

News May.08,2025

-

Essential Car Repair Kits Every Vehicle Owner Should Know About

News May.08,2025

-

Engine Restoration Essentials: Tools and Kits Every Mechanic Needs

News May.08,2025

-

Critical Marine Bearing Components: Ensuring Smooth Sailing and Safe Hauling

News May.08,2025

-

Understanding Automotive Gaskets: Keeping Your Engine and Transmission Leak-Free

News May.07,2025

Products categories