Exploring the Advantages and Applications of BSP Bonded Seals in Modern Engineering Solutions

Understanding BSP Bonded Seals Importance and Applications

BSP bonded seals, also known as bonded washers or sealing rings, play a crucial role in various engineering applications, particularly in the realm of fluid connections. Their design and functionality are essential for ensuring leak-free performance in a wide range of industries, from automotive to aerospace and industrial machinery. This article will explore the significance of BSP bonded seals, their construction, and their applications.

What is a BSP Bonded Seal?

A BSP bonded seal is a type of sealing device that combines a metallic outer ring with a rubber or elastomeric inner composition. This unique structure provides excellent sealing properties ideal for high-pressure applications. The BSP nomenclature refers to British Standard Pipe threads, a standardized method for measuring and creating threaded pipes commonly used throughout the UK and other countries. The incorporation of bonded seals in BSP connections aids in achieving an effective seal, preventing the ingress of fluids or gases.

Construction and Materials

Typically, a BSP bonded seal consists of a metal ring, often made of aluminum, stainless steel, or brass, bonded with a rubber material like nitrile or silicone. The metallic portion serves to provide mechanical strength and support, while the elastomeric layer imparts flexibility and superior sealing capabilities. This combination ensures that the seal withstands a wide range of temperatures and pressures while maintaining excellent durability.

One of the key advantages of a bonded seal is the ability to absorb vibrations and thermal expansion variations, which are common in many industrial applications. This attribute reduces the risk of seal failure, thereby enhancing the overall longevity of machinery and equipment.

Applications in Industries

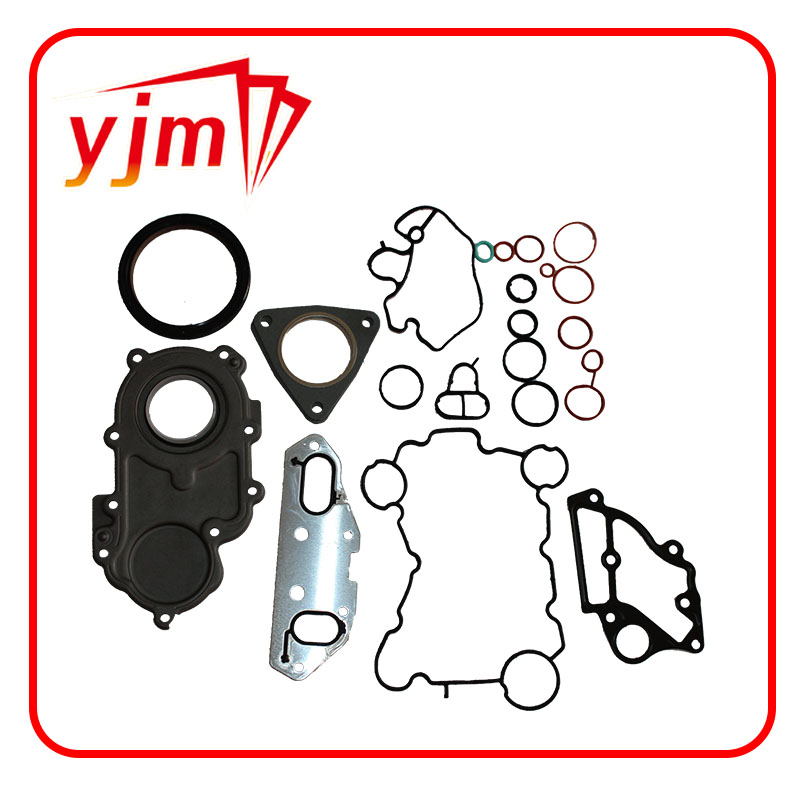

bsp bonded seal

BSP bonded seals are widely used in numerous applications across various industries due to their reliability and effectiveness. Some of the most common applications include

1. Automotive Industry In vehicles, BSP bonded seals are utilized in engine components, hydraulic systems, and fuel systems to prevent leaks. The seals help maintain pressure in critical systems, ensuring optimal performance and safety.

2. Aerospace The aerospace industry demands high standards for safety and reliability. BSP bonded seals are used in fuel systems, hydraulic systems, and pneumatic systems where the risk of fluid leakage could have catastrophic consequences. Their lightweight yet robust construction is crucial in aerospace applications.

3. Hydraulics and Pneumatics In hydraulic and pneumatic systems, BSP bonded seals offer a dependable solution for sealing threaded joints. This is particularly important in systems that operate under high pressures, where even the smallest leak can lead to significant operational failures.

4. Oil and Gas The oil and gas industry often operates in extreme conditions, where robust sealing solutions are vital. BSP bonded seals help in protecting against leaks in pipelines, connectors, and other critical equipment, contributing to the overall safety and efficiency of operations.

5. Manufacturing Plants In manufacturing environments, machinery that operates with fluids, such as coolant systems and lubrication systems, often employs BSP bonded seals. Their ability to maintain a seal under varying temperatures and pressures ensures consistent operation.

Conclusion

BSP bonded seals are indispensable components in modern engineering applications. Their unique design, combining metal and elastomeric materials, provides superior sealing capabilities essential for preventing leaks and ensuring the operational integrity of various systems. With applications spanning automotive, aerospace, hydraulics, oil and gas, and manufacturing, the relevance of BSP bonded seals cannot be overstated. As industries continue to evolve, the demand for reliable sealing solutions like bonded seals will only increase, underscoring the importance of this innovative technology in ensuring safety, efficiency, and longevity in equipment and machinery.

-

Understanding the Importance of the Crankshaft Oil Seal in Engine Performance

News Jun.16,2025

-

The Unsung Heroes of Engine Protection: Understanding Automotive Shaft Seals and Oil Seals

News Jun.16,2025

-

Keeping the Engine Tight: The Role of Crankshaft Seals and Gaskets in Oil Control

News Jun.16,2025

-

Complete Protection in Harsh Conditions: A Deep Dive into Cassette Seals

News Jun.16,2025

-

Choosing the Right Oil Seal: A Guide to Trusted Brands and Suppliers

News Jun.16,2025

-

Advanced Sealing Technologies: Exploring the Range of Modern Oil Seals

News Jun.16,2025

-

Your Essential Guide to Car Repair Kits: From Rust to Dings

News Jun.13,2025

Products categories