Understanding Pump Shaft Seals and Their Importance in Fluid Containment Systems

Understanding Pump Shaft Seals Importance and Functionality

In various industrial applications, pumps play a crucial role in transporting liquids efficiently and effectively. However, one of the critical components that ensure the smooth operation of pumps is the pump shaft seal. This component may seem small compared to the pump's overall size, but its role is vital in maintaining efficiency and preventing leaks.

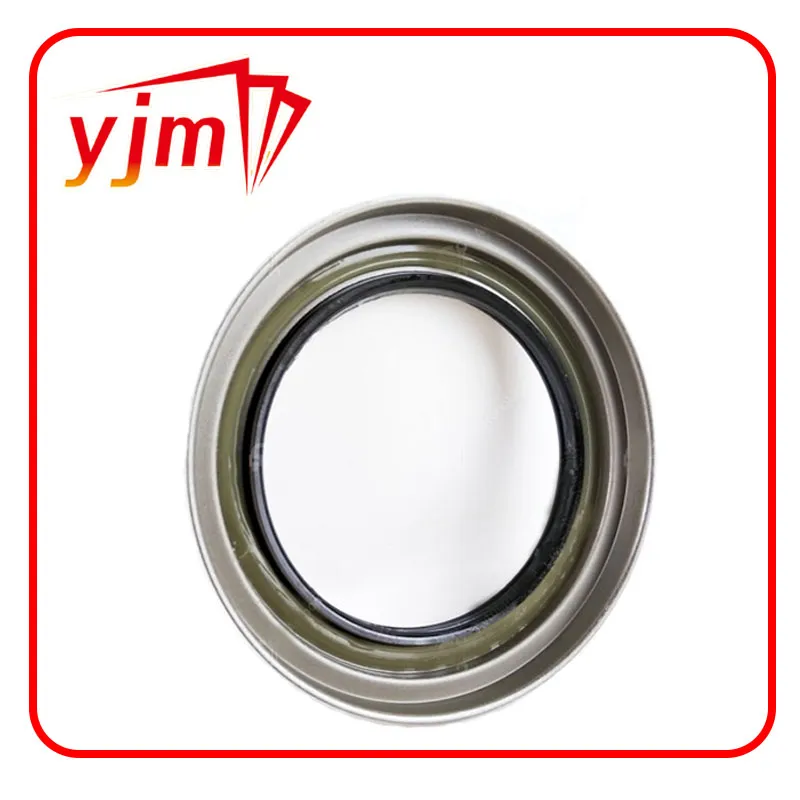

What is a Pump Shaft Seal?

A pump shaft seal is a device that prevents the fluid being pumped from leaking out along the shaft that drives the pump. It is typically positioned where the rotating shaft meets the pump casing and serves as a barrier between the fluid inside the pump and the external environment. Commonly made of rubber, Viton, silicone, or other materials, they are designed to withstand high pressures, temperatures, and various chemical properties of the mediums they are sealing.

Types of Pump Shaft Seals

There are several types of pump shaft seals, each tailored to specific applications

1. Mechanical Seals These are extensively used in centrifugal pumps and consist of two primary components a stationary part and a rotating part. Mechanical seals are preferred in applications where high efficiency and minimal leakage are required.

2. Packing Seals Packing seals involve the use of packing material, which is compressed to form a seal between the shaft and the pump casing. While they are simpler and often less expensive, they can require more maintenance and can lead to more leakage compared to mechanical seals.

3. Lip Seals Common in low-pressure applications, lip seals are often used in pumps handling non-aggressive liquids. They are easy to install and can provide good sealing capabilities for less critical applications.

Importance of Pump Shaft Seals

1. Leak Prevention One of the primary functions of a pump shaft seal is to prevent leaks. A good seal ensures that the liquid within the pump remains contained, preventing wastage and environmental contamination.

2. Pressure Maintenance Pump seals help to maintain the necessary pressure within the pump system. Any failure of the seal can result in significant drops in pressure, affecting the pump's performance and possibly leading to system failure.

pump shaft seal

3. Equipment Longevity By preventing leaks and maintaining pressure, shaft seals play a crucial role in prolonging the life of the pump. A well-sealed pump suffers less wear and tear and thus requires less frequent replacement or repair.

4. Safety In many industries, the fluids being pumped can be hazardous or corrosive. Efficient sealing protects workers and the environment from potentially dangerous spills and leaks.

Factors Influencing Seal Performance

Several factors can influence the performance of pump shaft seals, including

- Temperature and Pressure Extreme temperatures and pressures can affect the material properties of the seal, leading to premature failure. Selecting a seal that matches the operational conditions is essential for effective performance.

- Chemical Compatibility The fluid being pumped must be compatible with the seal material. Using the wrong material can cause deterioration and sealing failure.

- Shaft Alignment Misalignment of the pump shaft can lead to uneven wear on the seal, requiring proper installation and maintenance to ensure long-lasting performance.

Maintenance of Pump Shaft Seals

Regular maintenance and inspection of pump shaft seals are critical in preventing unplanned downtime. This includes checking for signs of wear, leakage, and misalignment, as well as ensuring that the seals are correctly lubricated (if applicable). Timely replacement of worn seals can save considerable costs related to fluid loss and equipment damage.

Conclusion

In summary, pump shaft seals are indispensable components that ensure the efficient and safe operation of pumps across various industries. Understanding their types, functions, and maintenance needs can greatly enhance performance and longevity, making them a critical focus in pump management and operation. Regular attention to these seals helps prevent costly leaks and extends the lifespan of the pumping equipment, ultimately contributing to a more efficient operational process.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories