oil seal 12x24x5

Understanding the Functionality and Importance of Oil Seals A Spotlight on the 12x24x5 Model

In the realm of machinery and automotive engineering, the oil seal plays a crucial role in maintaining the efficiency and longevity of various components. These small yet vital parts serve as barriers to prevent the leakage of lubricants and the ingress of dirt, dust, and moisture. Among the various types of oil seals available, the 12x24x5 oil seal stands out due to its specific dimensions and multifaceted applications across different industries.

What is an Oil Seal?

An oil seal, often referred to as a radial shaft seal, is a mechanical component that is designed to seal the area between rotating and stationary parts. Its primary purpose is to retain lubricants within the equipment while preventing contaminants from entering the system. This function is essential in various applications, including automotive engines, industrial machinery, and agricultural equipment.

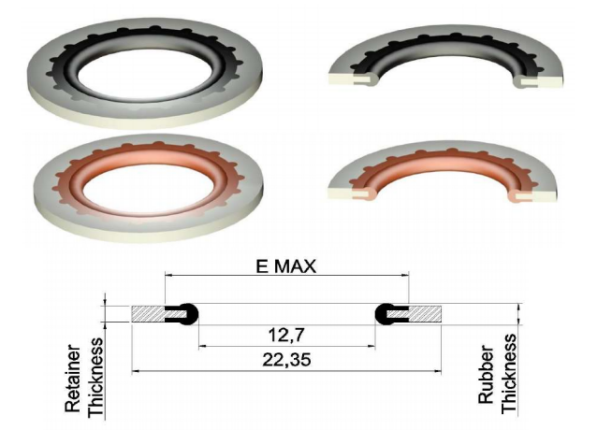

Key Features of the 12x24x5 Oil Seal

The designation 12x24x5 specifies the dimensions of the oil seal a 12 mm inner diameter, a 24 mm outer diameter, and a 5 mm thickness. These specific measurements make it suitable for a wide range of applications, including but not limited to

- Pumps Oil seals are commonly used in pumps to prevent leakage of oil or hydraulic fluid, ensuring efficient operation. - Motors In electric motors, oil seals help maintain lubrication while preventing contamination, which is critical for the overall performance and durability of the motor. - Gearboxes The 12x24x5 oil seal is often utilized in gearboxes to facilitate smooth operation by keeping lubricants contained and debris out.

Material Composition

The efficacy of an oil seal heavily relies on the materials used in its construction. Common materials include rubber, silicone, and thermoplastics, each offering specific benefits depending on the application. For a 12x24x5 oil seal, rubber is frequently used due to its excellent elasticity and resistance to wear, heat, and chemicals.

oil seal 12x24x5

Moreover, advanced materials like Viton and nitrile rubber provide enhanced performance in extreme conditions, such as high temperatures or aggressive chemicals. Consequently, selecting the right material for an oil seal is crucial for ensuring not only sealing capabilities but also longevity and reliability.

Installation Considerations

Proper installation of the 12x24x5 oil seal is essential for optimal performance. Here are some critical factors to consider

- Cleanliness Before installing the oil seal, ensure that the mating surfaces are clean and free of dirt or debris. Contamination can jeopardize the seal's effectiveness and lead to premature failure. - Alignment Proper alignment of the oil seal during installation can prevent excess wear and tear, ensuring a longer service life. - Tools Utilize the correct tools for installation to avoid damaging the seal. Specialized tools such as seal drivers can help achieve the right fit without causing harm.

Maintenance and Replacement

Although oil seals are designed for durability, they can eventually wear out due to factors such as temperature fluctuations, chemical exposure, and mechanical stress. Regular inspections are vital to identify signs of wear, such as grease leakage or visible damage. If a 12x24x5 oil seal is found to be compromised, timely replacement is crucial to avoid further damage to the machinery.

Conclusion

In summary, the 12x24x5 oil seal is a small yet indispensable component that enhances the performance and reliability of various machines. Understanding its design, material composition, installation process, and maintenance needs helps in leveraging its full potential. As industries continue to aim for higher efficiencies and lower operational costs, the significance of oil seals, especially specific models like the 12x24x5, cannot be overstated. By investing in quality oil seals and following best practices for their installation and upkeep, businesses can ensure smoother operations and longer-lasting machinery.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories