M18 Oil Drain Plug Specifications and Installation Guide for Optimal Performance

M18 Oil Drain Plug Importance and Maintenance

The M18 oil drain plug plays a pivotal role in the maintenance and functionality of various machinery and vehicles. Often overlooked, this small yet significant component is essential for ensuring that the oil system operates efficiently. Understanding its function, importance, and maintenance can prolong the life of your engine and improve overall performance.

What is an M18 Oil Drain Plug?

An M18 oil drain plug refers to a specific type of drain plug that features an M18 (metric) thread size. It is commonly found in engines and machinery that require regular oil changes. The plug allows for easy access to the oil sump, facilitating the draining of old oil and the introduction of fresh oil. Typically made from durable materials such as steel or aluminum, the M18 drain plug is designed to withstand high temperatures and corrosive environments, making it a reliable component in hydraulic systems, automotive engines, and other machinery.

Importance of the M18 Oil Drain Plug

The importance of the M18 oil drain plug cannot be understated. First and foremost, it serves as the gateway for old oil to exit the engine. Regular oil changes are crucial for the performance of any internal combustion engine, as they help remove contaminants and prevent sludge build-up. A faulty or improperly sealed drain plug can lead to oil leaks, leading to serious engine damage over time.

Moreover, the M18 drain plug ensures that the oil is retained within the lubrication system when the engine is not in operation. This capacity not only protects the engine from oil loss but also maintains appropriate oil levels, which are vital for the smooth functioning of engine components. Thus, ensuring that your M18 oil drain plug is in good condition is integral to the overall health of your engine.

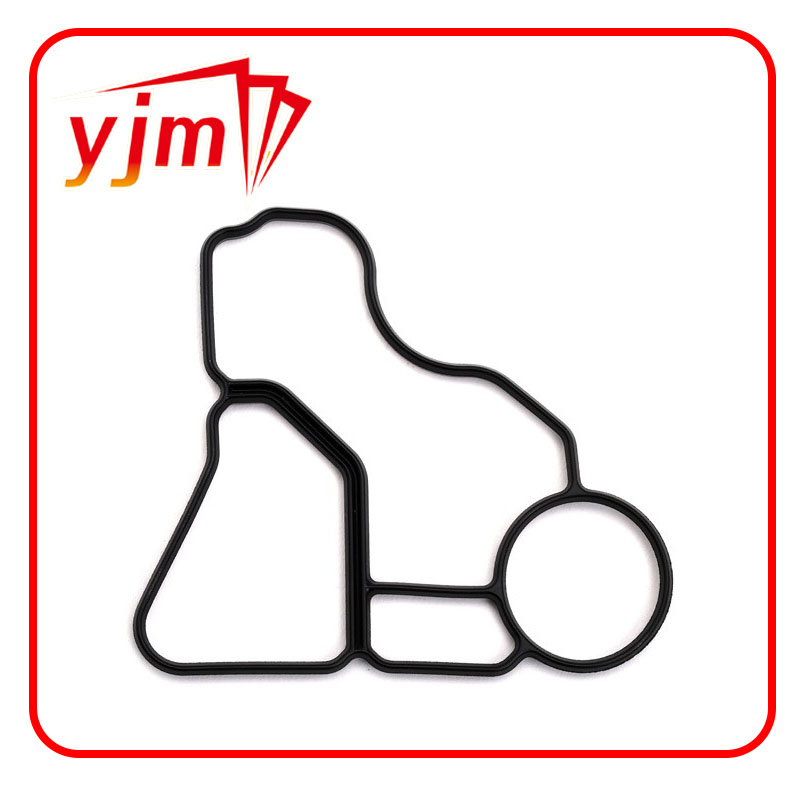

m18 oil drain plug

Maintenance Tips for the M18 Oil Drain Plug

Maintaining your M18 oil drain plug is relatively straightforward and involves a few key practices. Firstly, always inspect the condition of the drain plug during routine oil changes. Look for signs of wear, cross-threading, or deterioration of the sealing washer. If any issues are found, replacing the drain plug immediately is essential to prevent leaks.

Secondly, when installing the drain plug, make sure to apply the appropriate torque as specified in the manufacturer's guidelines. Over-tightening can cause damage to the threads, while under-tightening might result in leaks. Using a new sealing washer with each oil change can also help create a better seal, further reducing the risk of leaks.

Finally, always keep an eye on your oil levels and check under your vehicle for signs of oil leaks. A suspicious puddle or a burnt oil smell could indicate a problem with the drain plug or other components of the oil system. Addressing these issues promptly can save you from more significant engine troubles down the line.

Conclusion

While the M18 oil drain plug may seem like a minor component in the broader context of engine maintenance, its significance cannot be overlooked. By understanding its role and implementing proper maintenance practices, you can ensure a longer, more efficient operation of your engine. Regular inspections and careful handling of the drain plug can lead to a well-functioning engine, ultimately saving time, money, and stress. Keeping the M18 oil drain plug in optimal condition will go a long way in preserving the health of your vehicle or machinery.

-

Understanding the Importance of the Crankshaft Oil Seal in Engine Performance

News Jun.16,2025

-

The Unsung Heroes of Engine Protection: Understanding Automotive Shaft Seals and Oil Seals

News Jun.16,2025

-

Keeping the Engine Tight: The Role of Crankshaft Seals and Gaskets in Oil Control

News Jun.16,2025

-

Complete Protection in Harsh Conditions: A Deep Dive into Cassette Seals

News Jun.16,2025

-

Choosing the Right Oil Seal: A Guide to Trusted Brands and Suppliers

News Jun.16,2025

-

Advanced Sealing Technologies: Exploring the Range of Modern Oil Seals

News Jun.16,2025

-

Your Essential Guide to Car Repair Kits: From Rust to Dings

News Jun.13,2025

Products categories