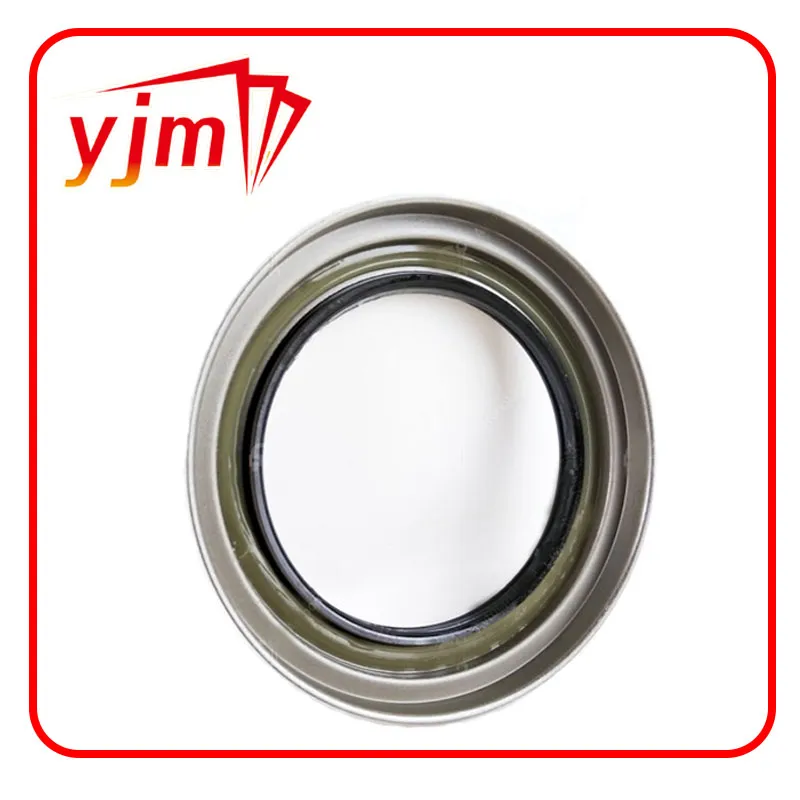

gasket flat face

Understanding Gasket Flat Face Importance and Applications

Gaskets are critical components in various mechanical systems, ensuring the integrity of joints and preventing leaks of fluids or gases. Among the different types of gaskets, the flat face gasket holds a significant position due to its simplistic design and versatility. This article will delve into the characteristics, applications, and significance of gasket flat faces in industrial settings.

What is a Gasket Flat Face?

A flat face gasket is a type of sealing material that is characterized by its flat surface, which is typically made from materials such as rubber, silicone, cork, or composite materials. Unlike raised face gaskets, which feature a protruding edge that enhances sealing capability, flat face gaskets rely on uniform pressure across their surface to create a seal. This design allows for even distribution of compressive forces when the gasket is compressed between two mating surfaces.

Key Characteristics

1. Material Composition The material used for flat face gaskets varies depending on the application. Common choices include non-asbestos materials, PTFE (polytetrafluoroethylene), and elastomers that can withstand varying temperatures and chemical exposure.

2. Thickness and Size Flat face gaskets come in various thicknesses and sizes to accommodate different flanges and operational conditions. Choosing the right thickness is crucial, as it affects the compression and, consequently, the sealing capability.

3. Pressure and Temperature Resistance Many flat face gaskets are designed to withstand high pressure and temperature. For instance, some are engineered to handle extreme conditions found in oil and gas applications, ensuring safety and reliability.

Applications of Flat Face Gaskets

Flat face gaskets are widely used in several industries, including

gasket flat face

1. Oil and Gas In the oil and gas sector, flat face gaskets are crucial for pipeline joints and flanged connections. They provide reliable seals that prevent leaks of hydrocarbons, ensuring safety and regulatory compliance.

2. Chemical Processing The chemical industry requires gaskets that can withstand corrosive substances. Flat face gaskets made from PTFE or other resistant materials are often employed to prevent leaks in reactors and other equipment.

3. Automotive Flat face gaskets are commonly found in engines and transmission systems, where they play a vital role in maintaining pressure and preventing fluid leaks. Their ability to handle high temperatures is particularly important in automotive applications.

4. HVAC Systems In heating, ventilation, and air conditioning systems, flat face gaskets are used to seal joints where air or refrigerants must be prevented from escaping. Their durability ensures efficient system operation.

5. Food and Beverage Hygienic seals are paramount in the food and beverage industry. Flat face gaskets made from FDA-approved materials are utilized in tank connections and piping systems to prevent contamination.

Importance of Proper Installation

The effectiveness of flat face gaskets significantly depends on proper installation. Ensuring parallelism between flanges, using the right torque specifications, and avoiding over-tightening are crucial for achieving a proper seal. A poorly installed gasket can lead to leaks, which could result in operational failures and potential safety hazards.

Conclusion

Flat face gaskets are a fundamental aspect of various industrial applications, valued for their simplicity and effectiveness in creating seals. Understanding their characteristics, applications, and the importance of proper installation is crucial for engineers and maintenance personnel alike. As industries continue to evolve, the development of new materials and designs for flat face gaskets will enhance their performance, making them even more reliable in meeting the challenges of modern engineering. Whether in oil rigs, chemical plants, or automotive workshops, flat face gaskets remain an unsung hero, quietly ensuring the safe and efficient operation of countless systems.

-

Your Essential Guide to Car Repair Kits: From Rust to Dings

News Jun.13,2025

-

Understanding Vital Engine Seals: Key Gaskets in Diesel and Performance Engines

News Jun.13,2025

-

The Vital Role of Bearings in Marine and Boating Applications

News Jun.13,2025

-

Sealing the System: A Complete Guide to Engine Oil Gaskets

News Jun.13,2025

-

Sealing the Foundation: A Complete Guide to Engine and Transmission Pan Gaskets

News Jun.13,2025

-

Essential Bearings and Hubs for Marine Vessels and Trailers

News Jun.13,2025

-

Your Complete Guide to Automotive Oil Drain Plugs and Valves

News Jun.12,2025

Products categories