Flat Rope Gaskets for Enhanced Sealing Solutions in Various Applications

Understanding Flat Rope Gaskets A Comprehensive Overview

Flat rope gaskets play a crucial role in various industries where sealing solutions are essential to prevent leaks and maintain efficiency in systems. This article delves into what flat rope gaskets are, their applications, materials, advantages, and how they compare to other sealing solutions.

What is a Flat Rope Gasket?

A flat rope gasket is a type of sealing material that is typically manufactured in a rectangular or flat shape. These gaskets are made from a range of materials and are designed to fill the space between two surfaces, creating a tight seal to prevent the escape of fluids or gases. The design of a flat rope gasket allows it to be compressed firmly when securing two surfaces together, ensuring a high level of sealing performance.

Applications of Flat Rope Gaskets

Flat rope gaskets are widely utilized in various applications due to their versatility. Common uses include

1. Automotive Industry In vehicles, flat rope gaskets are often employed around engine components to prevent oil and coolant leaks. Their ability to withstand high temperatures and pressures makes them suitable for this environment. 2. Industrial Machinery Many industrial applications, including pumps, compressors, and turbines, use flat rope gaskets to create seals that endure harsh conditions. They help to maintain the efficiency of machinery by preventing fluid loss.

3. HVAC Systems In heating, ventilation, and air conditioning systems, flat rope gaskets help to seal off ducts and connections, ensuring hot or cold air is delivered efficiently without energy loss.

4. Chemical Processing The chemical industry uses flat rope gaskets in tanks, reactors, and pipelines to contain various substances, including corrosive materials. Their material composition can be tailored to resist specific chemicals.

Materials Used in Flat Rope Gaskets

Flat rope gaskets can be made from a variety of materials, each offering different properties suited for specific applications

- Graphite Excellent for high-temperature applications, graphite gaskets are ideal for environments where heat resistance is required.

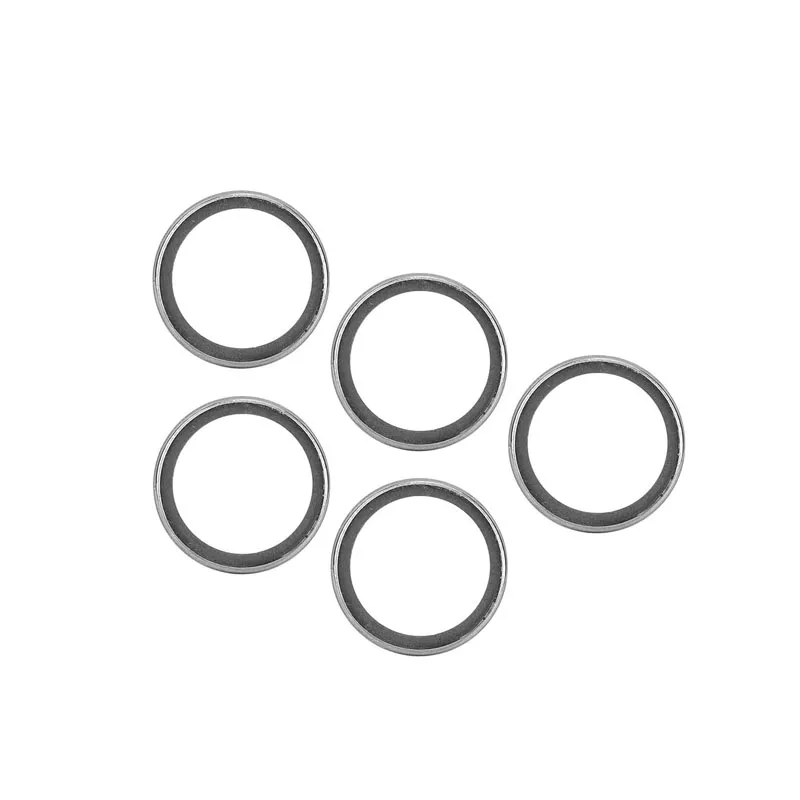

flat rope gasket

- PTFE (Teflon) Known for its chemical resistance, PTFE gaskets are suitable for harsh chemical applications and can also handle a wide temperature range.

- Fiberglass Often used in electrical applications, fiberglass gaskets provide insulation and are resistant to heat.

- Rubber Various rubber compounds offer flexibility, compliance, and resistance to water and other liquids, making them a popular choice for fluid sealing.

- Aramid Fibers These are used for enhanced strength and durability, often found in high-pressure applications.

Advantages of Flat Rope Gaskets

1. Customizable Flat rope gaskets can be manufactured in various sizes and shapes, allowing them to fit into unique applications and spaces.

2. Cost-Effective Compared to more complex sealing solutions, flat rope gaskets are simpler in design, making them an economical option for manufacturers and maintenance teams.

3. Ease of Installation Their flat design allows for straightforward installation and replacement, reducing downtime during maintenance.

4. Effective Sealing When compressed, flat rope gaskets offer a reliable seal that minimizes the potential for leaks in critical applications.

Conclusion

In conclusion, flat rope gaskets are essential components in many industrial and commercial applications. Their versatility, range of materials, and effective sealing capabilities make them a go-to solution for engineers and maintenance professionals alike. As industries continue to evolve and demand more efficient sealing solutions, the importance of flat rope gaskets will only grow, driving innovations in materials and designs to meet these challenges. Understanding their properties and applications can lead to enhanced performance and longevity in systems relying on effective sealing solutions.

-

Oil Drain Plug Washer Reusable Types

News Aug.22,2025

-

Oil Drain Plug Replacement Guide

News Aug.22,2025

-

Heavy Duty Seal Waterproof Features

News Aug.22,2025

-

Engine Oil Seals Installation Guide

News Aug.22,2025

-

Seal Oil for Sale High Temperature Grade

News Aug.22,2025

-

Cassette Seal Compact Design

News Aug.22,2025

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

Products categories