40x60x10 Oil Seal Specifications and Applications for Optimal Performance

Understanding Oil Seals A Focus on the 40 60 10 Model

Oil seals are essential components in a wide range of mechanical applications, playing a critical role in preventing the leakage of lubricants and fluids. One common type of oil seal is designated as 40 60 10, which provides specific dimensions and characteristics that make it suitable for various industrial uses.

What is an Oil Seal?

An oil seal, also known as a rotary seal or grease seal, is a mechanical component made of elastomers or rubber that forms a barrier between static and dynamic parts. Its primary function is to retain lubricant within the machinery while preventing contaminants like dirt, dust, and moisture from entering the system. This function is vital for ensuring the longevity and efficiency of several mechanical systems including engines, gearboxes, and pumps.

Analyzing the 40 60 10 Oil Seal

The designation 40 60 10 refers to the dimensions of the oil seal. In this context, the first number (40) indicates the inner diameter (ID) of the seal in millimeters, the second number (60) denotes the outer diameter (OD), also in millimeters, and the third number (10) represents the thickness of the seal in millimeters. Thus, the 40 60 10 oil seal has an inner diameter of 40 mm, an outer diameter of 60 mm, and a thickness of 10 mm.

These specific measurements make this model versatile, as it can fit a variety of shafts and housings in different types of machinery. Oil seals like the 40 60 10 are typically used in automotive applications, agricultural equipment, and other industrial machines where reliable sealing is paramount.

Material Composition

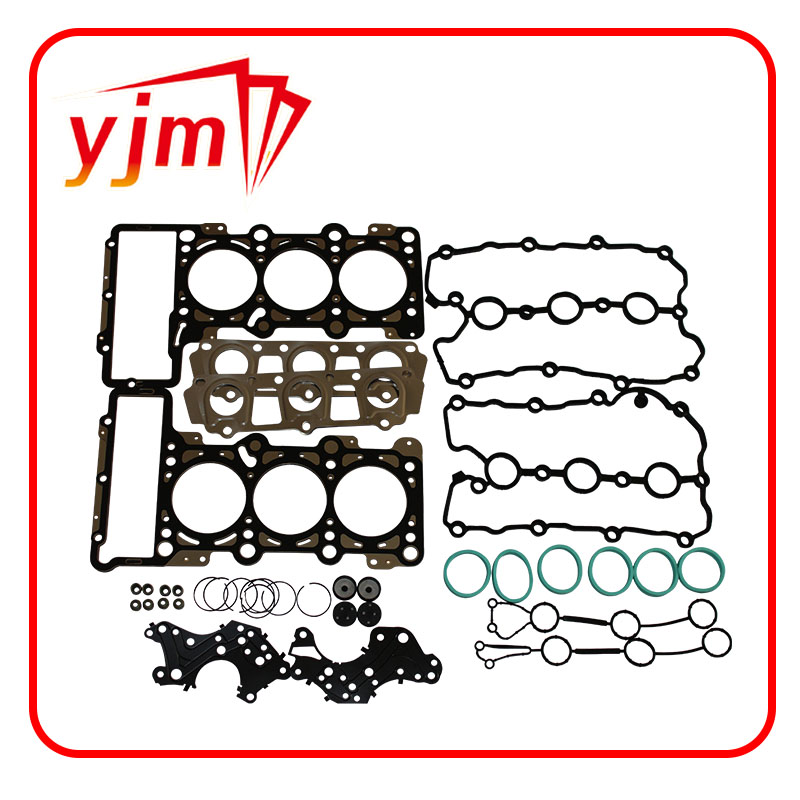

oil seal 40 60 10

Oil seals can be manufactured from various materials, depending on the application and the fluids they are intended to seal. Common materials include nitrile rubber (NBR), fluoroelastomers (FKM), and silicone rubber. Nitrile rubber is widely used for general applications due to its excellent wear resistance and oil tolerance. In contrast, fluoroelastomers are better suited for high-temperature and aggressive chemical environments.

The choice of material and the design of the oil seal contribute significantly to its performance, durability, and resistance to degradation over time. For example, the 40 60 10 oil seal made of NBR would typically function well in standard automotive lubrication systems but may not withstand higher temperatures or aggressive chemicals.

Installation and Maintenance

Correct installation of the oil seal is crucial to its performance. Before installation, the sealing surface must be inspected for damage, cleanliness, and proper lubrication. The seal should be installed evenly to avoid distortion and should not be driven too deep to prevent undue stress that can lead to failure.

Regular inspection is also recommended to ensure that the oil seal is functioning effectively. Indicators of seal failure can include oil leaks, a decrease in lubrication, or increased friction in the machinery. Replacing oil seals like the 40 60 10 as part of scheduled maintenance can help prevent larger mechanical failures and extend the lifespan of machinery.

Conclusion

In conclusion, the oil seal 40 60 10 is a vital component in many mechanical systems, providing essential sealing capabilities to protect the integrity of lubricants while preventing contamination. Its specific dimensions make it a versatile choice for various applications, but the material selection and proper installation are key factors in its effectiveness. Understanding the role of oil seals helps in making informed decisions regarding maintenance and replacement, ultimately enhancing machine performance and reliability. Whether in automotive engines or heavy industrial equipment, the significance of oil seals, such as the 40 60 10 model, cannot be overstated.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories