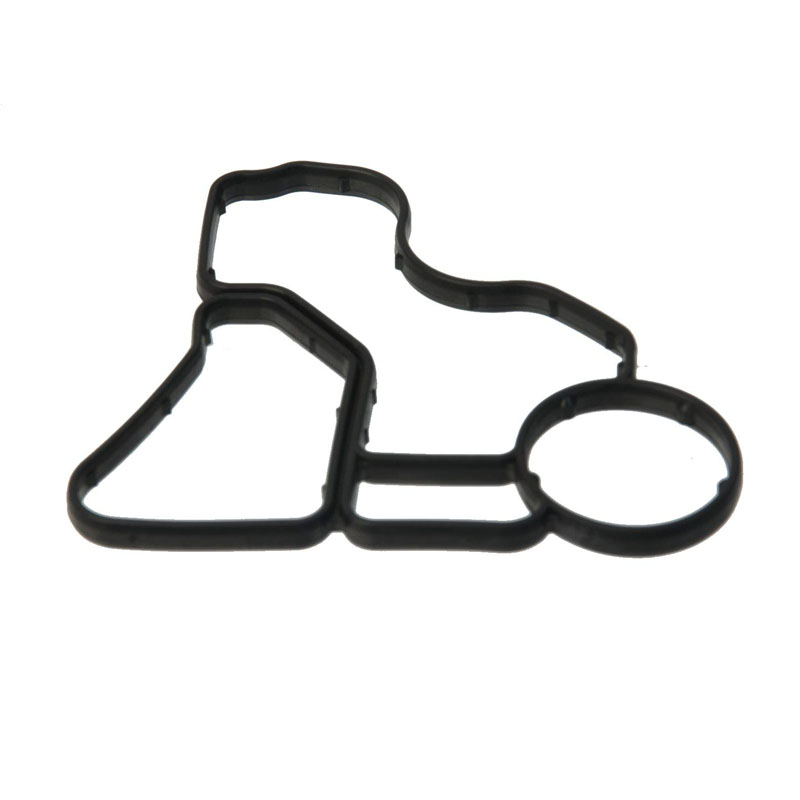

m14 aluminum crush washer

Understanding M14 Aluminum Crush Washers Essential Components for Effective Sealing

In the world of mechanical engineering and automotive applications, the importance of reliable sealing cannot be understated. One essential component that plays a crucial role in ensuring effective sealing is the aluminum crush washer, specifically the M14 aluminum crush washer. This specialized washer is designed to provide a secure and leak-proof seal in various applications, making it an invaluable asset for engineers and technicians alike.

Understanding M14 Aluminum Crush Washers Essential Components for Effective Sealing

When installed, the crush washer exerts uniform pressure when tightened, allowing it to deform slightly and fill gaps between the surfaces it joins. This deformation creates a tight seal that prevents fluid leaks, making it ideal for applications involving oil, fuel, and coolant. The M14 aluminum crush washer is particularly popular in automotive settings, where it is commonly used in oil drain plugs, transmission systems, and hydraulic lines.

m14 aluminum crush washer

Proper installation of M14 aluminum crush washers is crucial for optimal performance. Technicians must ensure that the washer is aligned correctly and that the surfaces it contacts are clean and free from debris. When tightened, the washer should crush evenly to create a reliable seal without over-compressing. Over-tightening can lead to deformation that compromises the washer’s integrity and ability to seal effectively.

The versatility of M14 aluminum crush washers extends beyond automotive applications. They are also found in numerous industrial settings, including machinery, plumbing, and aerospace. The ability to withstand high temperatures and pressures makes them suitable for a wide range of tasks.

In conclusion, M14 aluminum crush washers are integral to achieving effective seals in various applications. Their lightweight, durable, and corrosion-resistant properties make them a preferred choice across multiple industries. Understanding their function and proper installation techniques can significantly reduce the risks of leaks and ensure the longevity of mechanical assemblies. As technology progresses, these small yet powerful components will continue to be vital in mechanical design and engineering.

-

The Ultimate Solution with Bonded Seal Kits

News May.15,2025

-

The Essential Guide to Oil Drain Plugs: The Innovations You Need

News May.15,2025

-

Shaft Seals: Ensuring Reliable Performance in Your Machinery

News May.15,2025

-

Polaris Ranger Front Differential: Performance and Durability You Can Trust

News May.15,2025

-

Everything You Need to Know About Oil Plug Washers

News May.15,2025

-

Crankshaft Oil Seals: Protecting Your Engine's Integrity

News May.15,2025

-

Understanding the Importance of Replacing Your Oil Filter Housing Gasket

News May.14,2025

Products categories