Understanding the Importance of Front and Rear Crankshaft Seals in Engine Performance

The Importance of Front and Rear Crankshaft Seals in Engine Performance

The crankshaft is a crucial component of an internal combustion engine, playing a pivotal role in converting the linear motion of pistons into rotational motion. To ensure the efficient operation of this complex system, the front and rear crankshaft seals are indispensable. These seals help maintain the proper functioning of the engine by preventing oil leaks and keeping contaminants at bay. In this article, we will delve into the functions, types, and maintenance of these vital components.

Functions of Crankshaft Seals

The primary purpose of front and rear crankshaft seals is to contain the engine oil within the crankcase while allowing the crankshaft to rotate freely. The seals create a barrier that prevents oil from leaking out and dirt and debris from entering the engine. This containment is crucial because engine oil lubricates various engine components, reducing friction and wear. With effective seals in place, the engine can maintain optimal oil pressure and ensure smooth operation.

The front crankshaft seal is located at the front of the engine, often near the timing belt or timing chain. This seal protects the crankshaft from contaminants and prevents oil from leaking out of the front of the engine. The rear crankshaft seal, on the other hand, is positioned at the rear of the engine, near the transmission. It serves a similar function by sealing the crankshaft on the transmission side, preventing oil loss and protecting the engine from external contaminants.

Types of Crankshaft Seals

There are several types of crankshaft seals, each designed to meet specific requirements

. The most common types include1. Lip Seals These are the most widely used crankshaft seals, featuring a flexible lip that presses against the rotating crankshaft. Lip seals are effective at preventing leaks and are available in various materials to suit different applications.

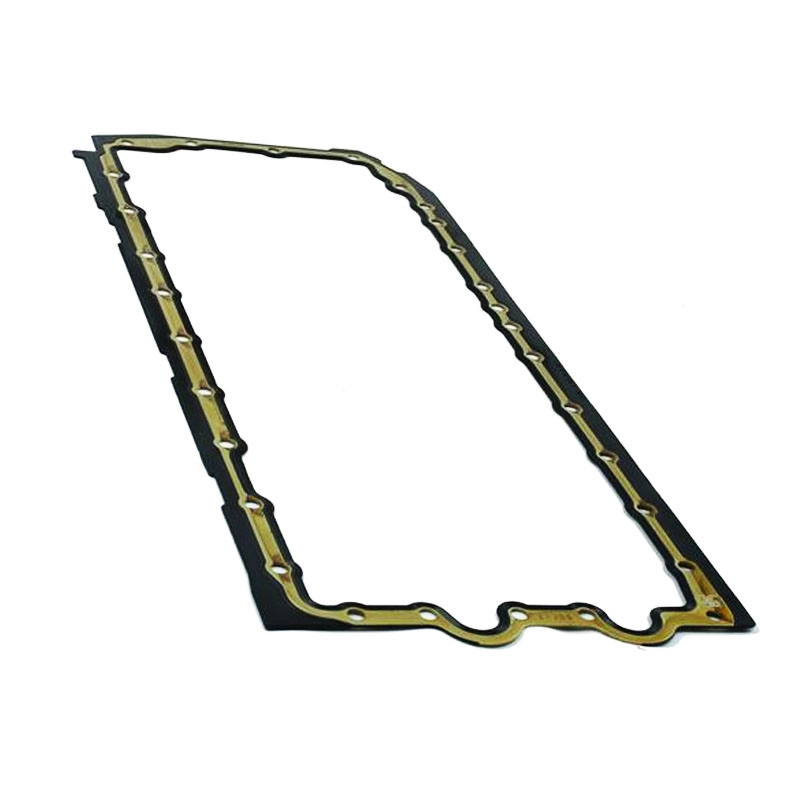

front and rear crankshaft seals

2. Face Seals These seals use a flat surface to create a leak-proof seal. Though less common in crankshaft applications, they may be found in high-performance engines where tighter tolerances are necessary.

3. PTFE Seals Made from polytetrafluoroethylene, these seals offer excellent resistance to wear and high temperatures. They are ideal for extreme operating conditions and are often used in racing applications.

Maintenance and Replacement

Regular maintenance of front and rear crankshaft seals is essential to ensure their longevity and prevent oil leaks. Signs of a failing seal may include oil spots under the vehicle, a drop in oil pressure, or unusual engine noise. If any of these symptoms are observed, it’s crucial to have the seals inspected and replaced if necessary.

Replacing crankshaft seals requires some mechanical knowledge and tools. Typically, the process involves removing the timing belt or chain, accessing the crankshaft, and carefully replacing the old seals with new ones. It is vital to ensure that the new seals are correctly installed to prevent future leaks.

Conclusion

Front and rear crankshaft seals are critical to the health and performance of an engine. By preventing oil leaks and protecting the engine from harmful contaminants, these seals play a vital role in ensuring the smooth operation of the vehicle. Regular inspection and timely replacement of worn seals can lead to improved engine efficiency and longevity. Understanding the significance of these components can help vehicle owners maintain their engines effectively, ensuring a reliable and long-lasting performance.

-

Understanding the Importance of the Crankshaft Oil Seal in Engine Performance

News Jun.16,2025

-

The Unsung Heroes of Engine Protection: Understanding Automotive Shaft Seals and Oil Seals

News Jun.16,2025

-

Keeping the Engine Tight: The Role of Crankshaft Seals and Gaskets in Oil Control

News Jun.16,2025

-

Complete Protection in Harsh Conditions: A Deep Dive into Cassette Seals

News Jun.16,2025

-

Choosing the Right Oil Seal: A Guide to Trusted Brands and Suppliers

News Jun.16,2025

-

Advanced Sealing Technologies: Exploring the Range of Modern Oil Seals

News Jun.16,2025

-

Your Essential Guide to Car Repair Kits: From Rust to Dings

News Jun.13,2025

Products categories